High-temperature-resistant rapid forming injection mold

An injection mold, high-temperature-resistant technology, applied in the field of high-temperature-resistant rapid prototyping injection molds, can solve problems such as position deviation, increased difficulty of molten material injection, and loss of lower mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

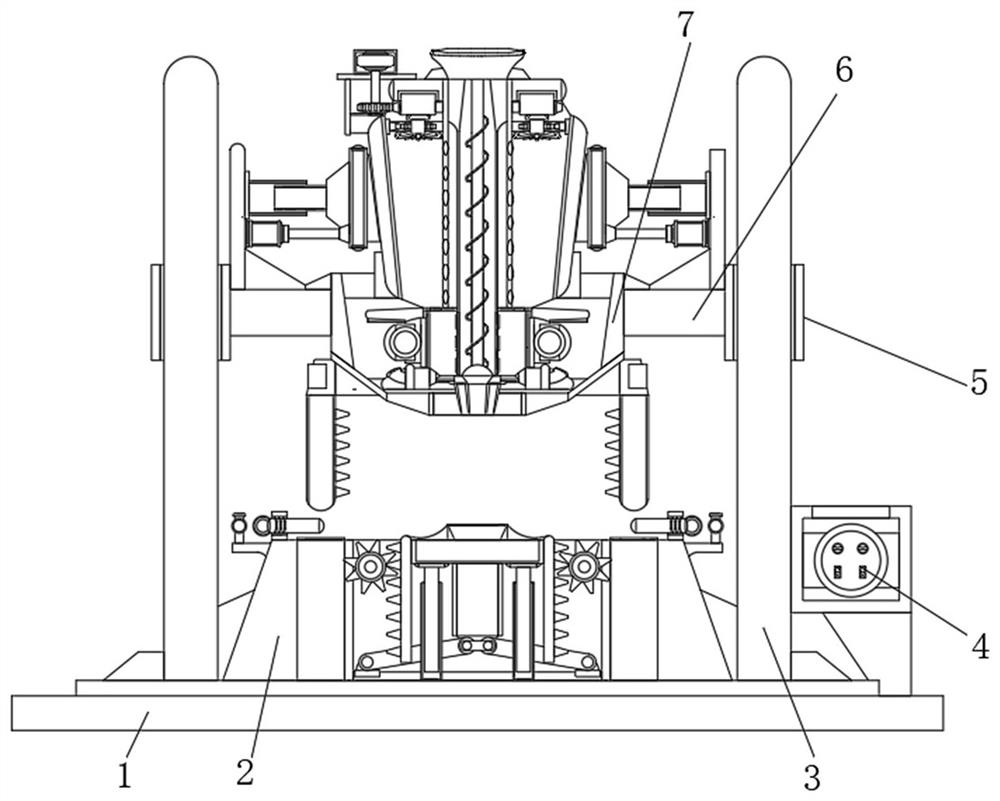

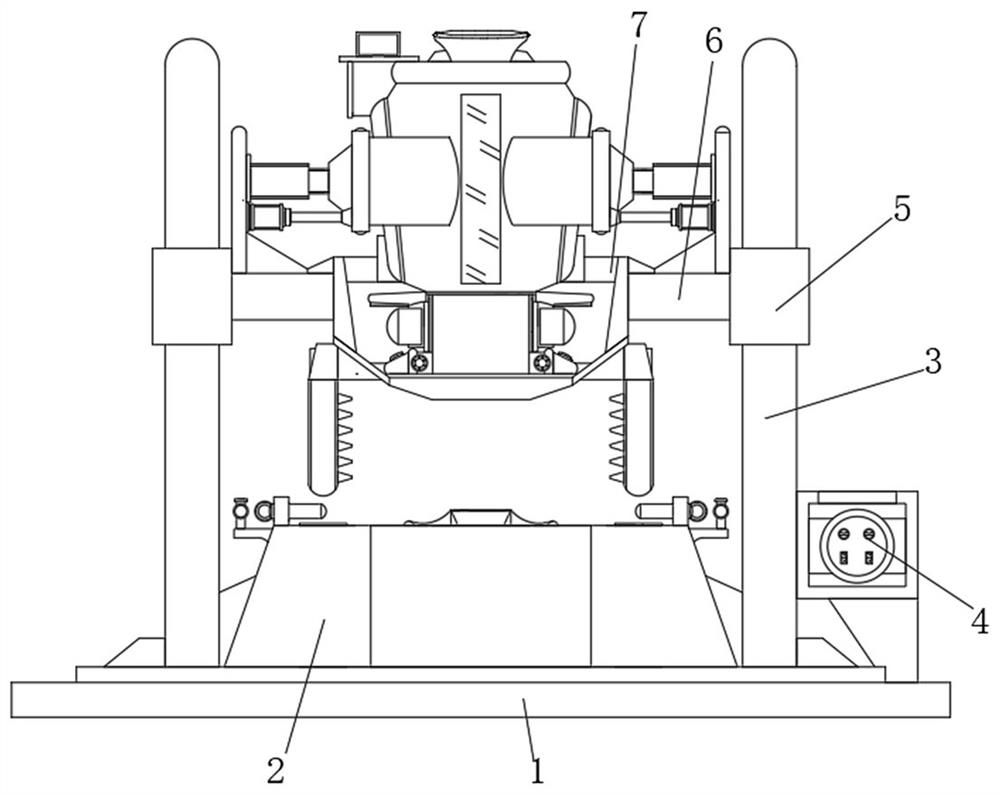

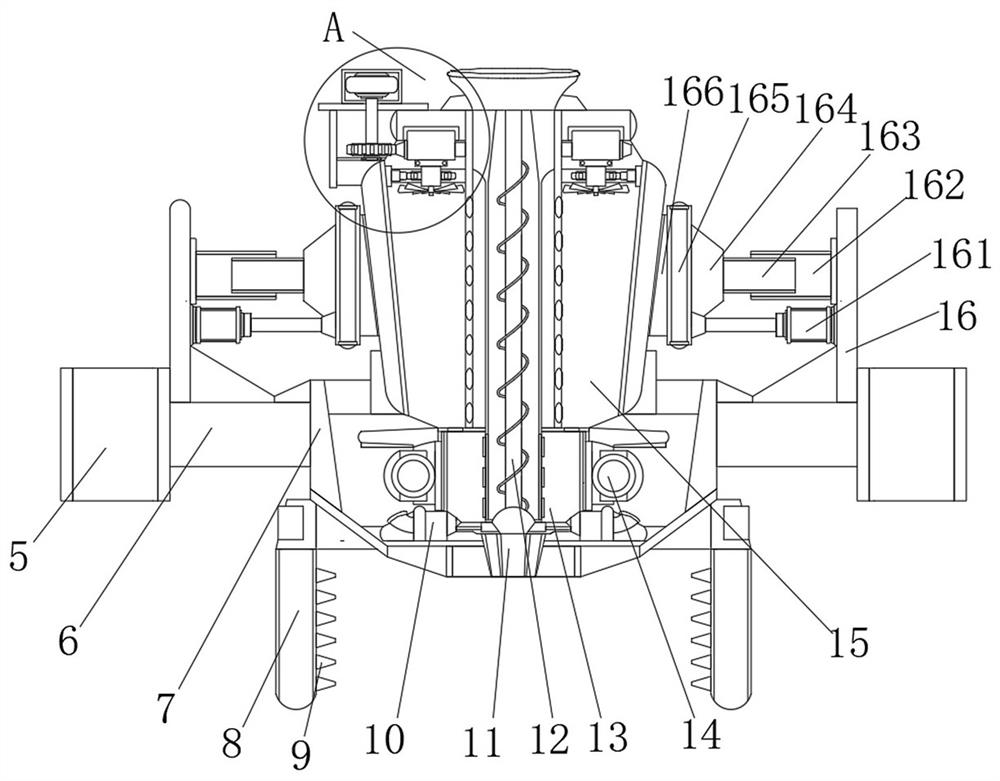

[0043] Example 1, such as image 3 and Figure 6 As shown, when the upper mold base 7 moves as a whole, the electric cylinder 161 can be activated through the console 4 to drive the installation plate 164 to approach inward under the guidance of the outer sleeve 162 and the inner sleeve 163, so that the installation plate 164 drives the sound-absorbing panel 165 The rock wool sleeve 15 is fitted and clamped with the semi-arc clamping wall 166, which not only provides a fitting and fixing effect on the outer wall of the rock wool sleeve 15, but also absorbs the impact and noise received by the rock wool sleeve 15, and passes through the semi-arc The shape of the clamping wall 166 is used for buffering and shock absorption, and the scattered fit of the sound-absorbing plate 165 and the sound-absorbing hole 167 is used to disperse and eliminate the noise, thereby increasing the functionality of the device.

Embodiment 2

[0044] Example 2, such as image 3 and Figure 4 As shown, when the molten material is guided from the injection molding tube 12, the heat source is infiltrated into the rock wool casing 15 through the injection molding tube 12, and the drive motor 221 is used to start the drive motor 221 to drive the gear B223 to rotate through the injection molding tube 12, so that the gear B223 drives the meshing The outer ring gear 224 of the outer ring gear 224 makes the slider 222 rotate in a ring under the rotation of the annular chute 22. With the rotation of the slider 222, the rotating rod 227 and the gear C226 are forced to rotate under the meshing fit with the inner ring gear 225. The rod 227 drives the fan blade 228 to rotate to form a guide wind, and the heat source in the infiltration and rock wool sleeve 15 flows downward, so that the heat source is guided from the annular guide flow groove 23 to the heat insulation cavity while dissipating heat from the injection tube 12 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com