Automatic sealing machine

An automatic sealing machine and sealing technology, applied in the direction of closures, thin material processing, winding strips, etc., can solve the problems of increasing the height of the container, increasing the container, polluting the bottle body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

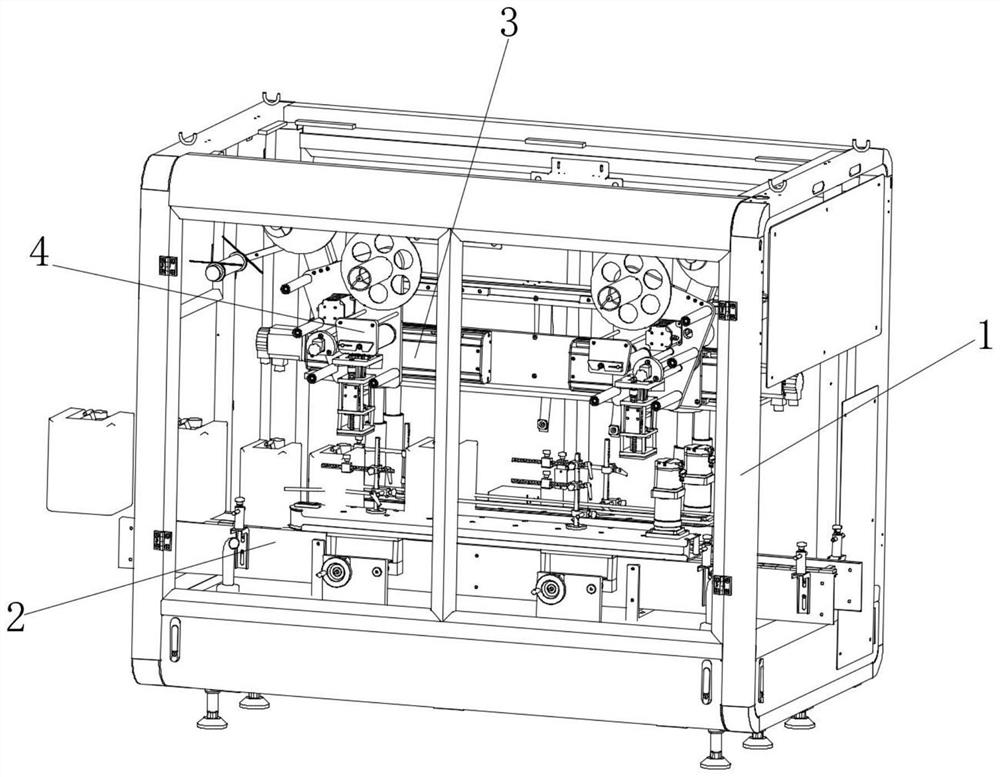

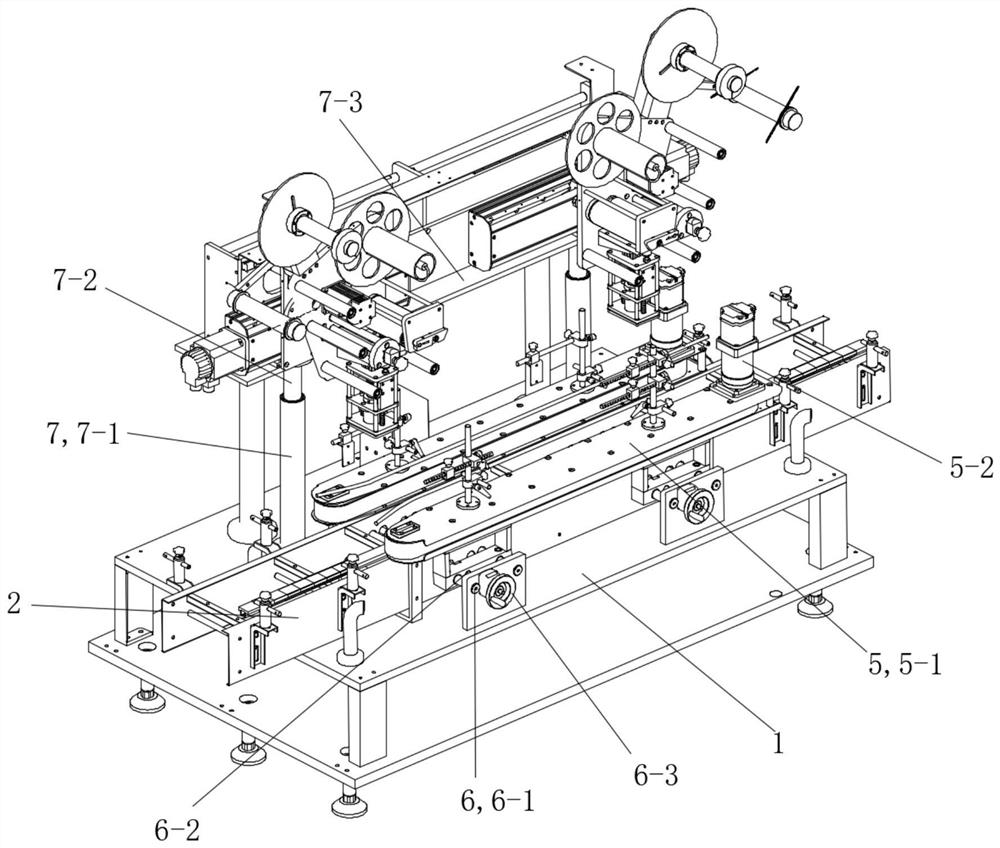

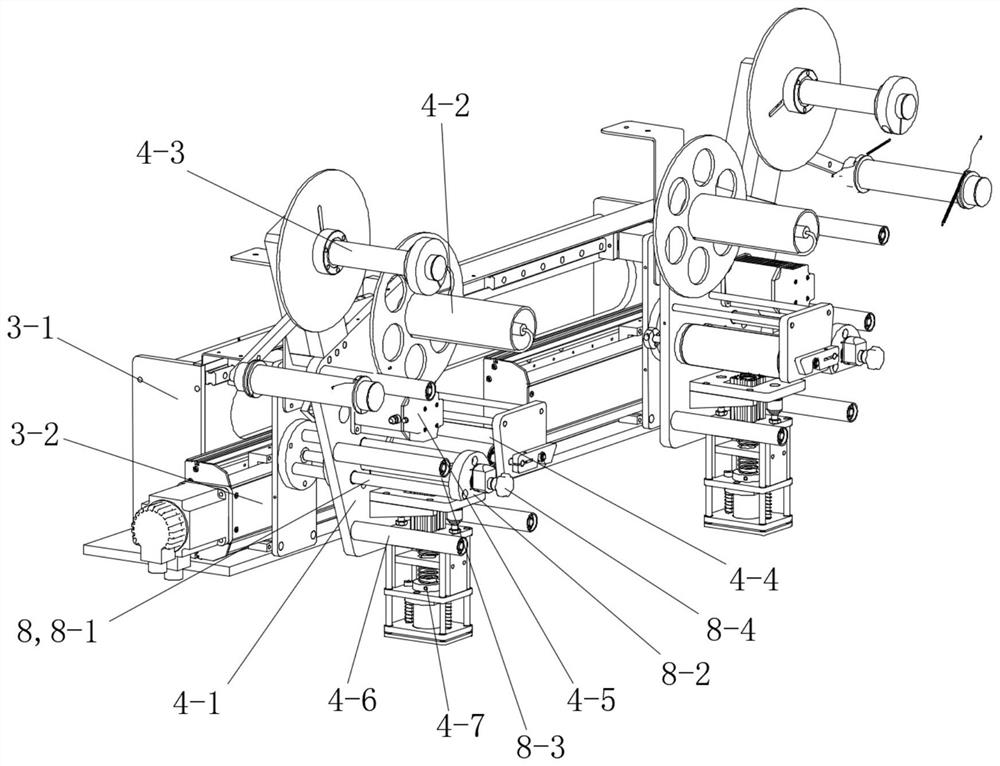

[0027] See Figure 1 to Figure 4 , the automatic sealing machine of this embodiment includes a frame 1 and a conveying line 2 arranged on the frame 1 . A follower mechanism 3 that can move synchronously with the bottles conveyed on the conveying line 2 is provided above the conveying line 2 . The following mechanism 3 is provided with a sealing mechanism 4 for sealing the bottle.

[0028] Further, both sides of the conveying line 2 are symmetrically provided with a decelerating mechanism 5 for decelerating the bottles entering the conveying line 2. The decelerating mechanism 5 includes a conveying frame 5-1, and the two ends of the conveying frame 5-1 are respectively equipped with active Wheel and driven wheel, by belt transmission between the driving wheel and the driven wheel, the conveying frame 5-1 is provided with the driving wheel drive motor 5-2 that drives the driving wheel to run.

[0029] Further, the deceleration mechanism 5 is provided on both sides of the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com