Optical camouflage compatible laser protection material, preparation method and application thereof

A technology of laser protection and protective materials, which is applied in the fields of rayon manufacturing, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of inconvenient use, narrow wavelength range of laser protection, poor aging performance, etc., and achieves simple preparation methods and high application The effect of wide range and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also proposes a preparation method of the above-mentioned novel laser protection material, comprising the following steps:

[0037] S1: Weigh squaraine dyes, cyanine dyes and methylcyanine dyes in parts by mass, stir with a glass rod for 3 to 5 minutes, and mix evenly to obtain a laser absorbing material;

[0038] S2: Weigh dispersant, coupling agent, ultraviolet aging aid, light stabilizer and antioxidant by mass parts, stir with a glass rod for 3-5 min, and mix uniformly to obtain a mixing aid;

[0039] S3: Weigh the laser absorbing material, organic solvent, transparent resin, toning pigment and auxiliary agent by mass parts of 0.5-5, 40-50, 40-60, 5-30 and 0.3-0.5, put the transparent resin at 60°C Seal and dry for 4h;

[0040] S4: Mix the laser absorbing material, the organic solvent, the dried transparent resin, the coloring pigment and the auxiliary agent, and stir at a speed of 300 to 500 r / min for 1 to 2 hours to make it evenly mixed to o...

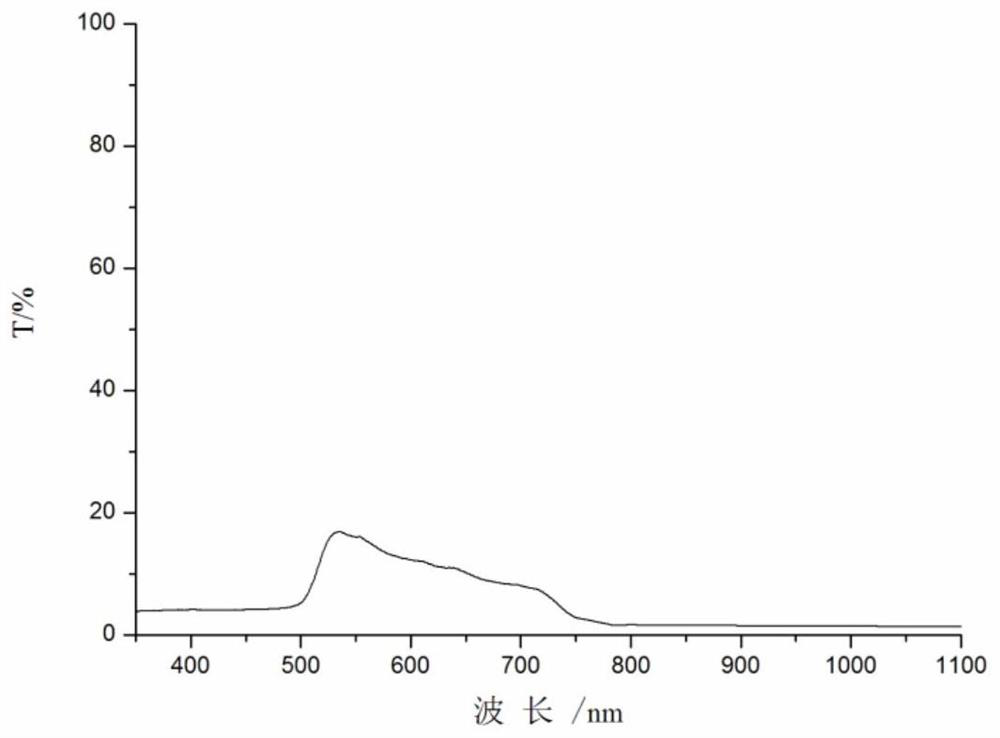

Embodiment 1

[0045] This embodiment provides an optical camouflage compatible laser protection material. The components in the protective film and their parts by mass are as follows: 2 parts by mass of laser absorbing material, 50 parts by mass of organic solvent, 50 parts by mass of transparent resin, and 10.5 parts by mass of coloring pigment parts by mass and 0.4 parts by mass of additives.

[0046] The present invention also proposes a method for preparing a laser protection material as described above, comprising the following steps:

[0047] S1: Weigh 20 parts by mass of squaraine dyes, 10 parts by mass of cyanine dyes, and 20 parts by mass of methyl cyanine dyes, stir with a glass rod for 3 to 5 minutes, and mix uniformly to obtain a laser absorbing material;

[0048] S2: weigh 30 parts by mass of dispersant, 10 parts by mass of coupling agent, 20 parts by mass of ultraviolet aging aid, 20 parts by mass of light stabilizer and 10 parts by mass of antioxidant, stir with a glass rod f...

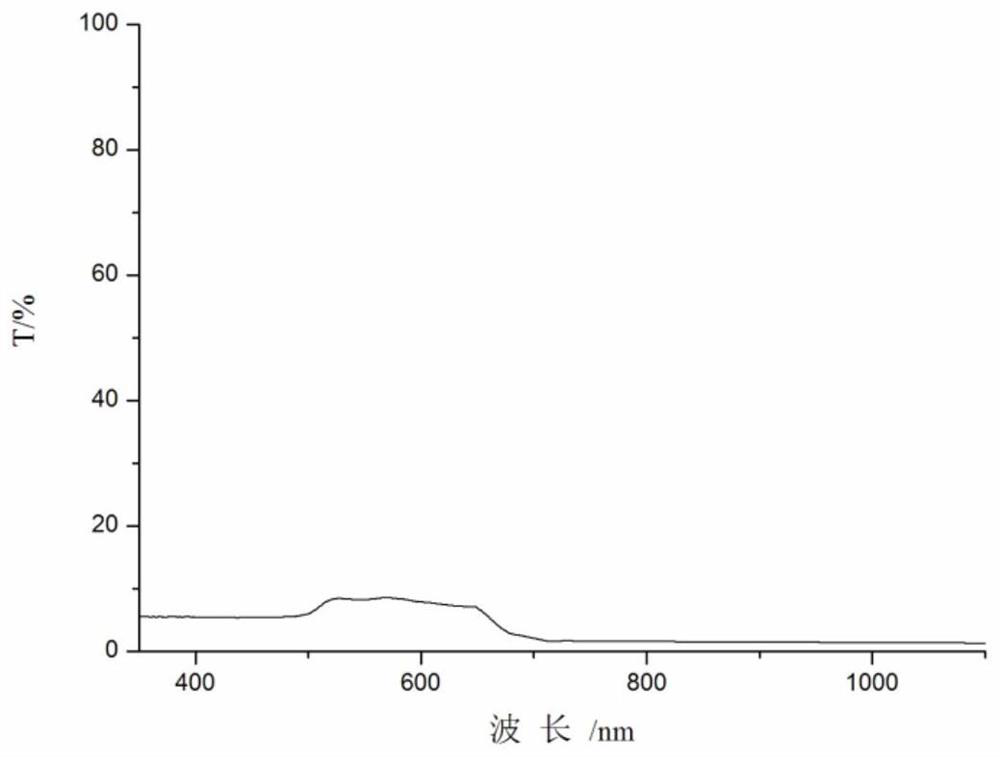

Embodiment 2

[0055] This embodiment provides an optical camouflage compatible laser protection material. The components in the protective film and their parts by mass are as follows: 2 parts by mass of laser absorbing material, 50 parts by mass of organic solvent, 40 parts by mass of transparent resin, and 18 parts by mass of coloring pigment parts by mass and 0.4 parts by mass of additives.

[0056] The present invention also proposes a method for preparing a protective film as described above, comprising the following steps:

[0057] S1: same as Example 1;

[0058] S2: same as Example 2;

[0059] S3: According to the requirements of dark green DG0730 laser stealth, weigh 2 parts by mass of laser absorbing material, 50 parts by mass of dimethylformamide, 40 parts by mass of transparent polyvinyl chloride, and coloring pigments (10 parts by mass of chrome green, 4 parts by mass of permanent yellow, 2 parts by mass of permanent red, 2 parts by mass of carbon black) and 0.4 part by mass of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com