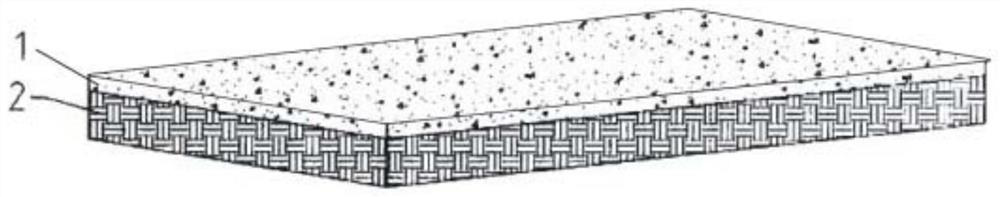

Stealth material compatible with laser and radar and preparation method thereof

A stealth material and stealth coating technology, applied in the field of stealth materials and their preparation, can solve the problems of ineffective compatibility with radar and optical camouflage performance, and achieve the effects of convenient production, convenient use, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

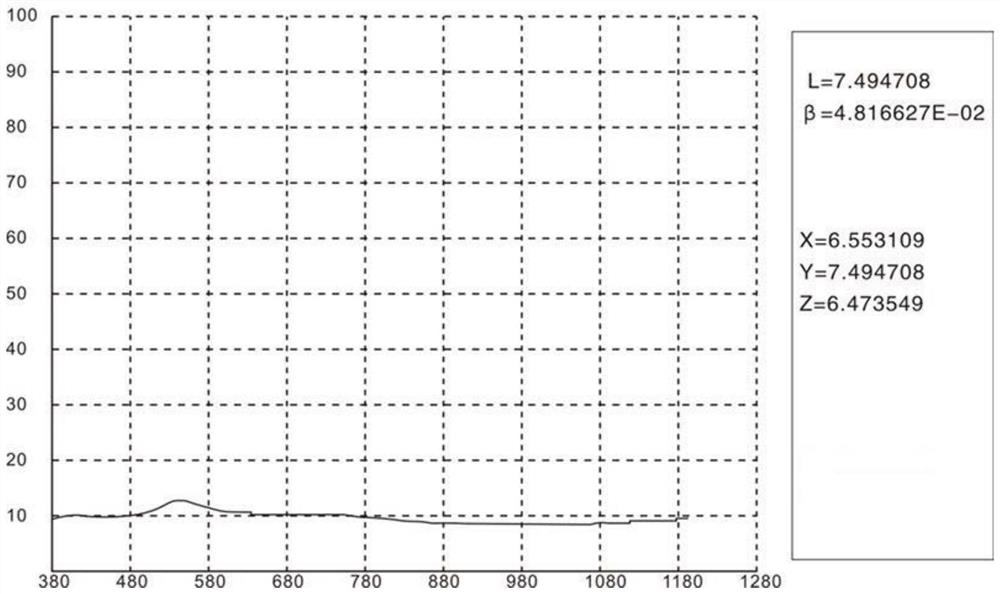

Embodiment 1

[0048] A stealth material compatible with laser and radar provided by a preferred embodiment of the present invention comprises the following components by mass: 40 parts of elastic polyester resin, 13 parts of chromium oxide green, 0.25 parts of titanium dioxide, and 10 parts of iron oxide yellow , 3.5 parts of iron oxide red, 5 parts of iron oxide black, 0.1 part of purple powder, 10 parts of laser absorbing pigment, 0.5 part of defoamer, 0.7 part of anti-sedimentation aid, 1 part of dispersant, 15 parts of composite solvent, 6 parts of matting agent Parts, 12 parts of elastic curing agent.

[0049] The preparation method of the above-mentioned stealth material compatible with laser and radar comprises the following steps:

[0050] Mix xylene, butyl acetate and propylene glycol methyl ether acetate in a volume ratio of 6:3:1 to form a composite solvent, and dissolve the dispersant in the composite solvent; weigh the formula amount of chromium oxide green, titanium dioxide, i...

Embodiment 2

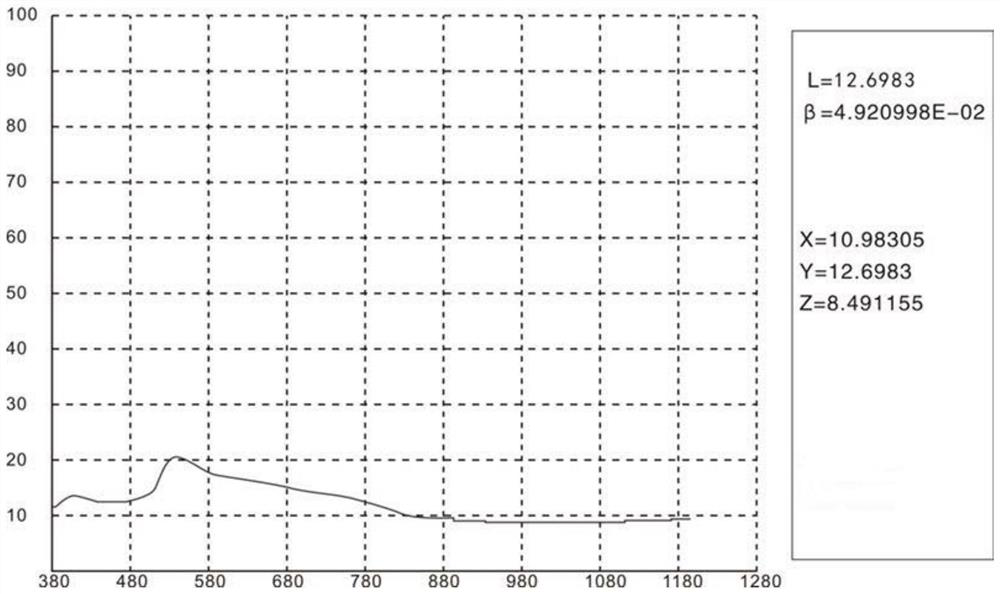

[0054] A stealth material compatible with laser and radar provided by a preferred embodiment of the present invention comprises the following components by mass: 42 parts of elastic polyester resin, 16 parts of chromium oxide green, 1 part of titanium dioxide, and 5 parts of iron oxide yellow , 0.5 parts of iron oxide red, 0.2 parts of iron oxide black, 0.1 parts of purple powder, 8 parts of laser absorbing pigment, 0.5 parts of defoamer, 0.5 parts of anti-sedimentation aid, 1 part of dispersant, 10 parts of composite solvent, 6 parts of matting agent Parts, 12 parts of elastic curing agent.

[0055] The preparation method of the above-mentioned stealth material compatible with laser and radar comprises the following steps:

[0056] Mix xylene, butyl acetate and propylene glycol methyl ether acetate in a volume ratio of 6:3:1 to form a composite solvent, and dissolve the dispersant in the composite solvent; weigh the formula amount of chromium oxide green, titanium dioxide, ir...

Embodiment 3

[0060] A stealth material compatible with laser and radar provided by the preferred embodiment of the present invention comprises the following components by mass: 50 parts of elastic polyester resin, 10 parts of chromium oxide green, 1.8 parts of titanium dioxide, and 8 parts of iron oxide yellow , 0.2 parts of iron oxide red, 0.1 parts of purple powder, 10 parts of laser absorbing pigment, 0.5 parts of defoamer, 0.5 parts of anti-sedimentation aid, 1 part of dispersant, 11 parts of composite solvent, 8 parts of matting agent, 14 parts of elastic curing agent share.

[0061] The preparation method of the above-mentioned stealth material compatible with laser and radar comprises the following steps:

[0062] Mix xylene, butyl acetate and propylene glycol methyl ether acetate in a volume ratio of 6:3:1 to form a composite solvent, and dissolve the dispersant in the composite solvent; weigh the formula amount of chromium oxide green, titanium dioxide, iron oxide Yellow, iron ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com