Device for producing sponge titanium by magnesium reduction method

A technology of reduction method and sponge titanium, which is applied in the field of equipment for producing sponge titanium by magnesium reduction method, and can solve the problems of concentrated feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0012]The present invention will be further described in conjunction with cross-sectional views and specific embodiments.

[0013]The present invention will be further described below with reference to the accompanying drawings, but it is not understood to the present invention, and without departing from the above technical ideology without departing from the present invention, there is a general technical knowledge and Various modifications, replacements, and modifications made by the usual means are included within the scope of the invention.

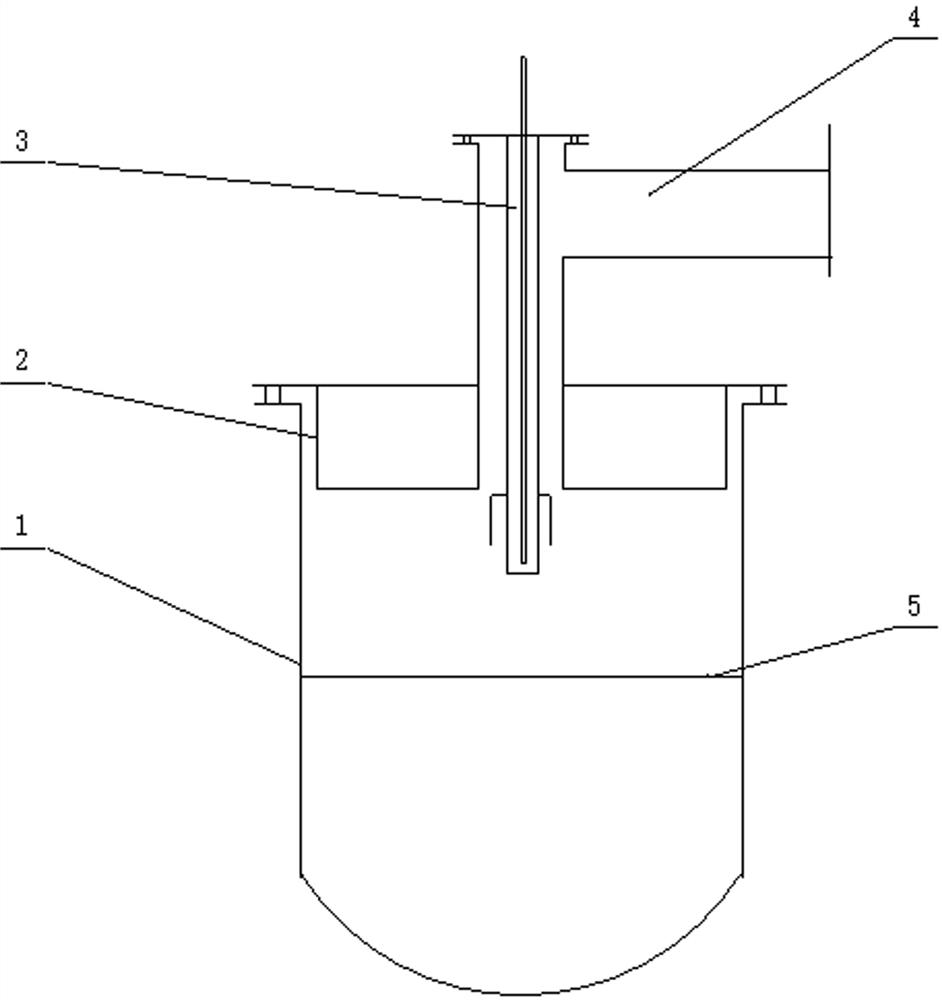

[0014]Such asfigure 1 withfigure 2As shown, a device for producing sponge titanium by magnesium reduction, mainly reactor 1, large cover 2, vaporization device 3, three-way tube 4, and magnesium surface 5; reactor 1 and the large cover 2 by bolts Connecting, a three-way tube 4 is provided on the large cover 1; the lower portion of the vaporization device 3 extends into the reactor 1;

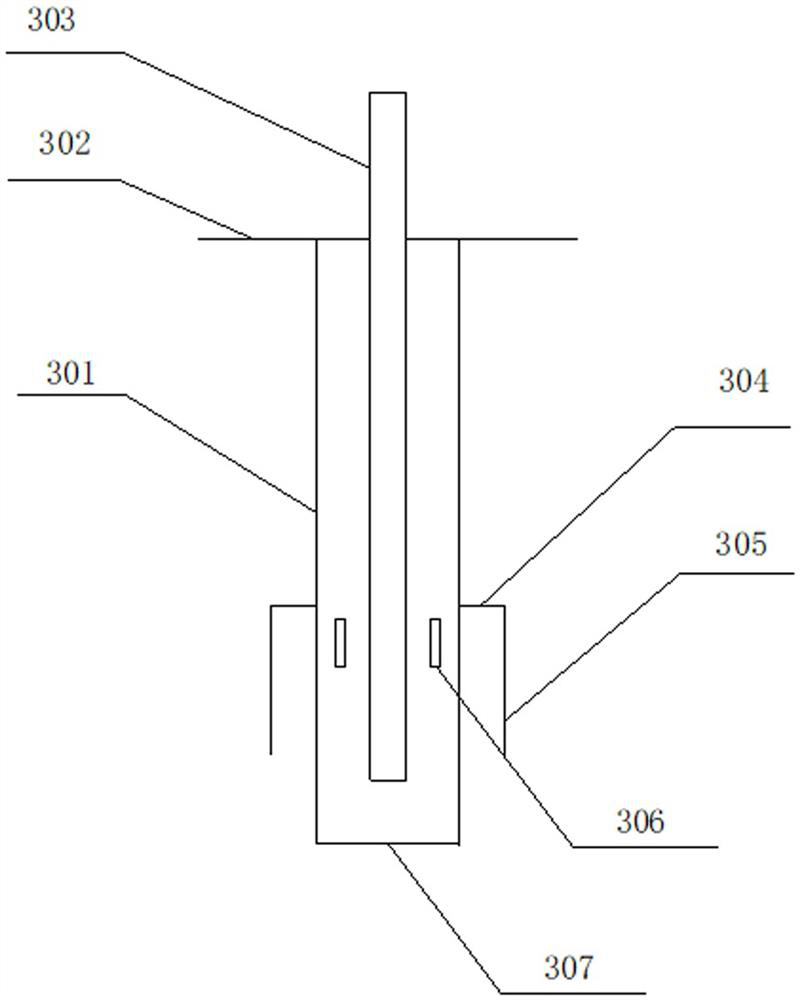

[0015]The vaporization device 3 consists of a cylinder 301, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com