Device and technology for preventing vacuum channel from being blocked in titanium sponge production

A technology of vacuum channel and titanium sponge is applied in the field of devices for preventing vacuum channel blockage, which can solve problems such as vacuum channel blockage, and achieve the effects of reducing labor intensity, saving power consumption of distillation production, and reducing product air intake rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

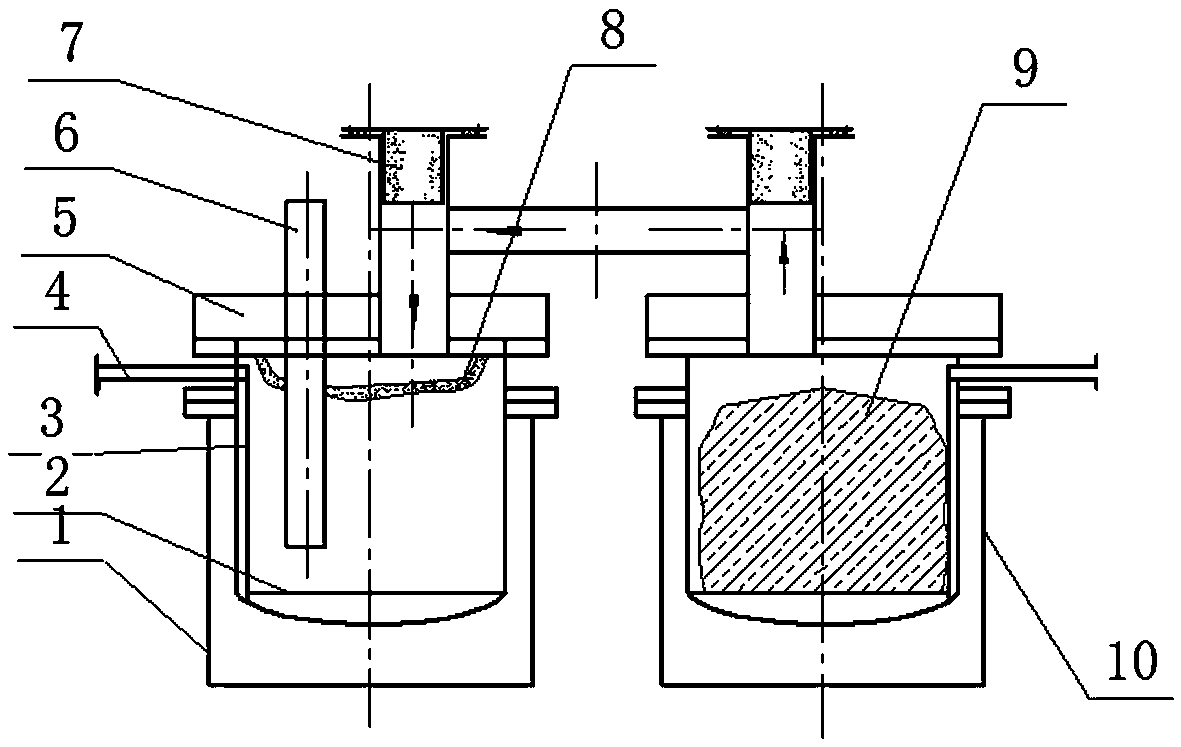

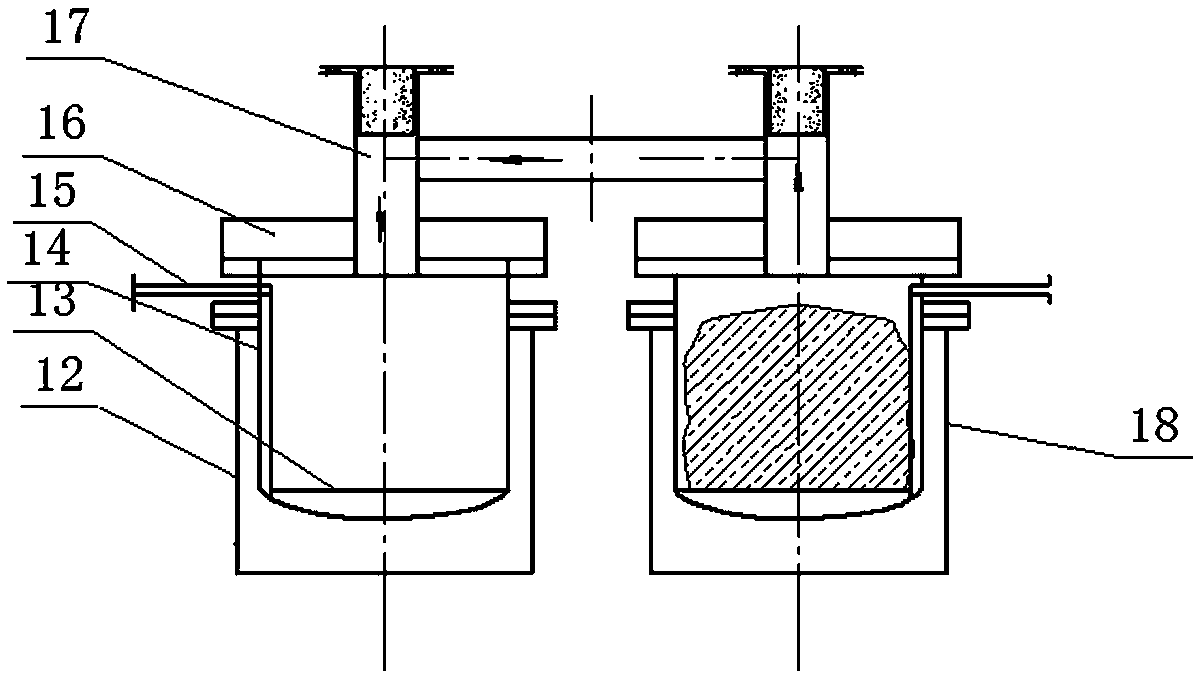

[0020] Such as image 3 Shown, a kind of anti-vacuum channel blocking device in the sponge titanium production comprises condenser 12, sieve plate 13, reactor 14, magnesium chloride tube 15, big cover 16, big cover riser 17 and heating furnace 18; It is characterized in that : the big cover riser 17 is arranged at the central position of the big cover 16.

[0021] A process for anti-vacuum channel blockage device in sponge titanium production, characterized in that:

[0022] After the reduction production is finished, hoist the assembled reactor 14, sieve plate 13 and large cover 16 into the condenser 12, pass cooling water into the condenser 12, connect the aisle, connect the magnesium chloride tube 15 to the vacuum system, and then carry out Exhaust the pressure, raise the temperature to 850°C, start low vacuum distillation at the same time, continue to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com