Device for enabling air flows to mutually communicate between titanium blocks during titanium sponge reduction distillation

A technology of sponge titanium and titanium lumps, which is applied in the field of devices for producing sponge titanium, can solve the problems that the vacuum air flow cannot penetrate each other, the titanium lump and the separation device are not easy to separate, and the distillation time is long, so as to shorten the distillation production cycle and structure Simplicity, effect of improving distillation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

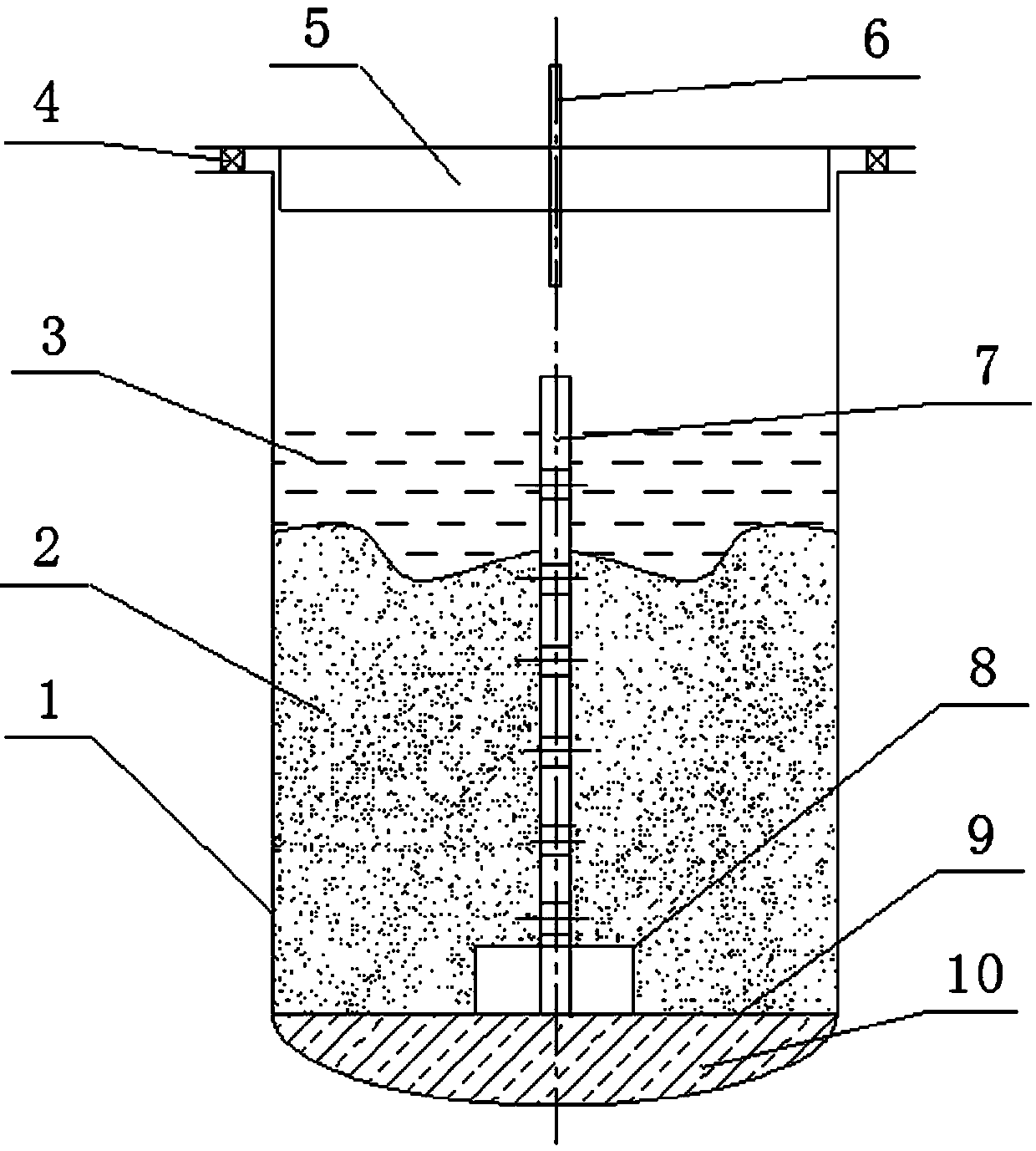

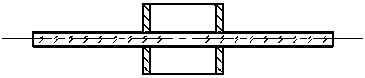

[0018] Such as figure 1 As shown, the reactor 1 forms a closed reduction distillation system through the sealing gasket 4 and the large cover 5, and the sieve plate 9 is placed on the reactor 1.

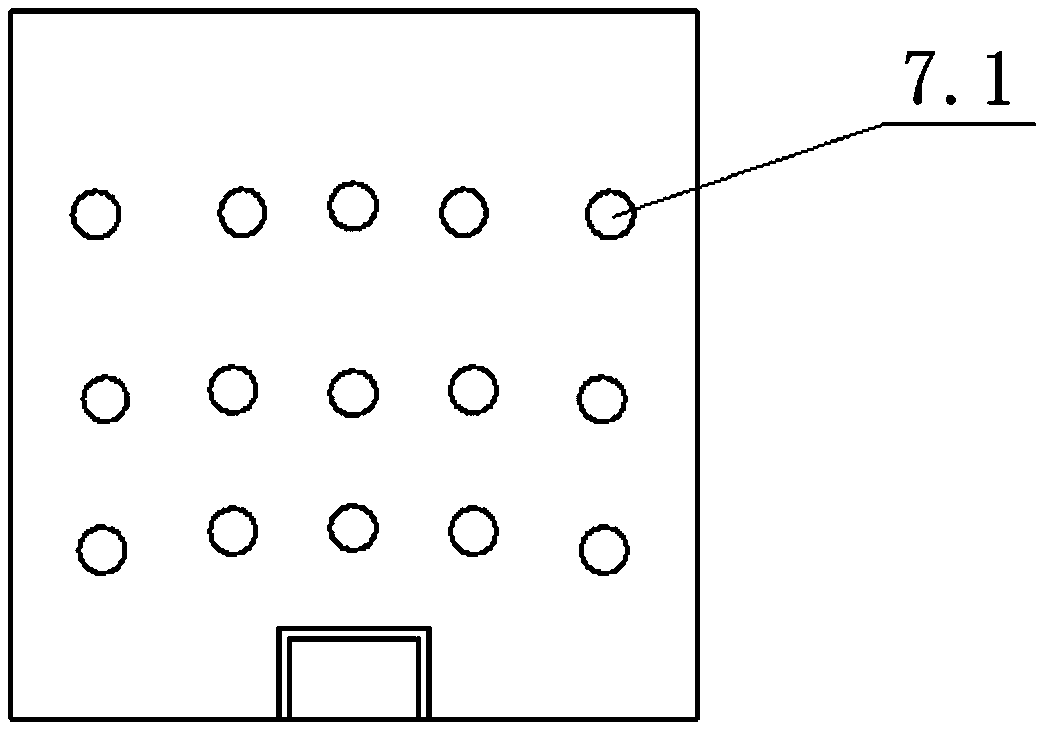

[0019] As shown in Figures 2 and 3, the device for allowing the airflow between the titanium lumps to communicate with each other during the reduction distillation of the sponge titanium includes a partition plate 7; 10-20 airflow holes 7.1 are provided on the partition plate 7, and one end of the titanium lump 2 The airflow can enter the other end of the titanium lump 2 through the airflow hole 7.1 on the partition plate 7, so that the airflow at both ends of the titanium lump 2 can communicate with each other, so as to increase the distillation effect and shorten the distillation time.

[0020] The unsealed box body 8 is welded symmetrically at the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com