Concrete frame column roll welding spiral stirrup reinforcement cage and preparation method thereof

A technology of spiral stirrups and steel cages, which is applied in the directions of columns, piers, pillars, etc., can solve the problem that multi-layer composite spiral stirrups do not provide solutions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

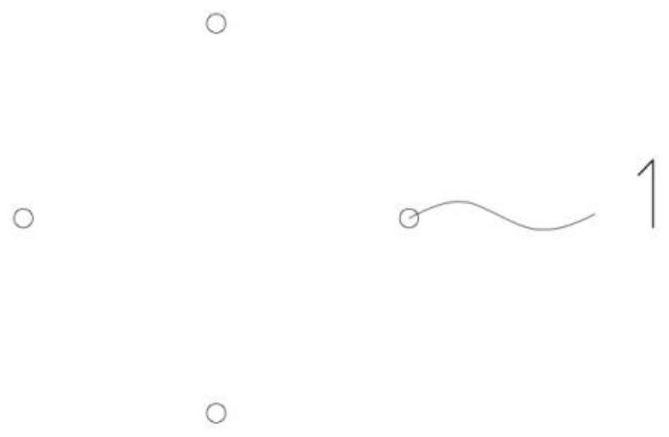

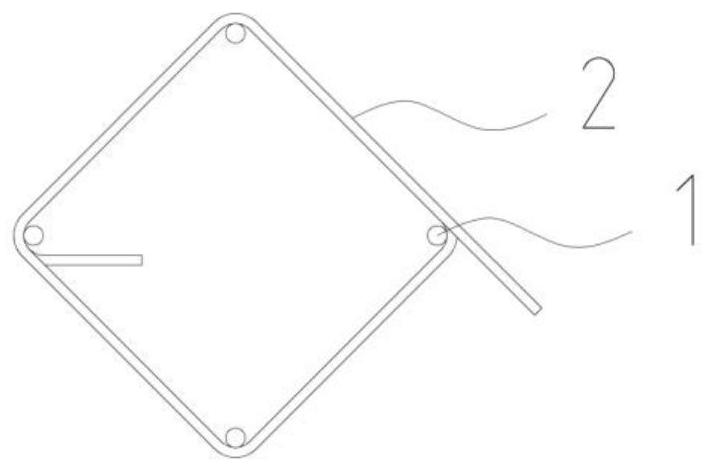

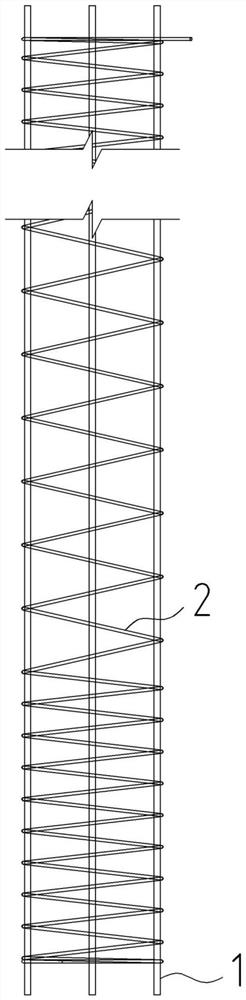

[0044] A concrete frame column roll welded spiral stirrup reinforcement cage, such as Figure 1 to Figure 9 As shown, the column roll welded spiral stirrup reinforcement cage 7 includes an inner ring longitudinal reinforcement 1, an inner ring polygonal spiral stirrup 2, a middle longitudinal reinforcement 3, a middle polygonal spiral stirrup 4, an outer ring longitudinal reinforcement 5 and an outer ring polygonal spiral stirrup Tendon 6;

[0045] Such as figure 2 and image 3 As shown, the inner ring longitudinal steel bar 1 is at the inner side of the corner of the inner ring polygonal spiral stirrup 2, and the inner ring polygonal spiral stirrup 2 is wound around the outer side of the inner ring longitudinal steel bar 1 and bent at the position of the inner ring longitudinal steel bar 1;

[0046] Such as Figure 5 and Figure 6 As shown, the middle longitudinal steel bar 3 is at the inner side of the corner of the middle polygonal spiral stirrup 4, and the middle poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com