An adjustable combined staircase steel formwork for high-rise buildings

An adjustable technology for high-rise buildings, applied to the preparation of building components on site, construction, building construction, etc., can solve problems such as unstable structures and performance, reduce the probability of brittle deformation, facilitate use, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

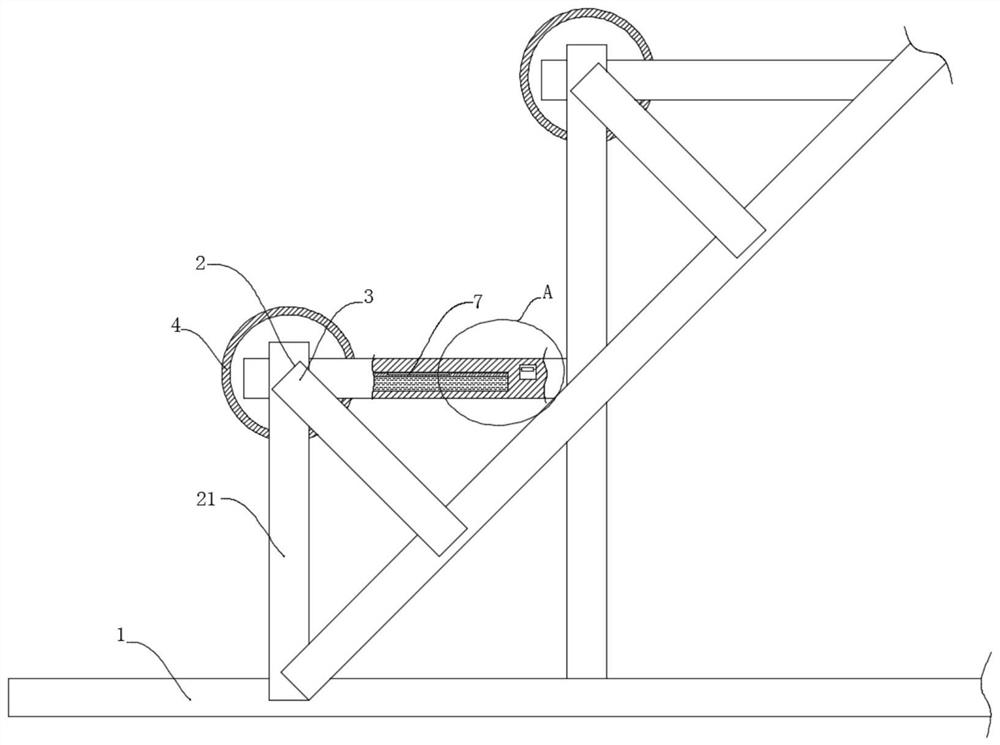

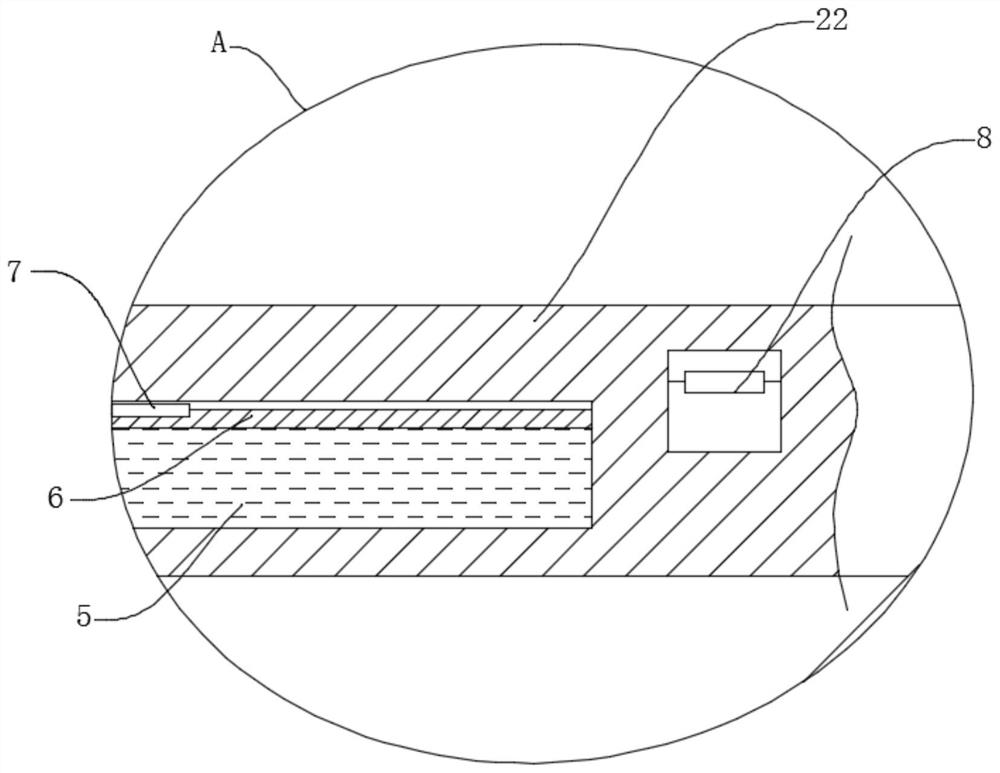

[0022] refer to Figure 1-3 , an adjustable combined staircase steel formwork for high-rise buildings, including a bottom plate 1 and a support plate 2, the support plate 2 includes a vertical plate 21 and a horizontal plate 22, and the connection between the vertical plate 21 and the horizontal plate 22 is fixedly connected with a slanting plate 3. The other end of the slant plate 3 is fixedly connected to the support. A liquid chamber 5 is opened in each horizontal plate 22. The liquid chamber 5 is filled with a buffer liquid. The inner wall of the liquid chamber 5 is slidingly connected with a pressure guiding plate 6. A piezoelectric sheet 7 is embedded on the top;

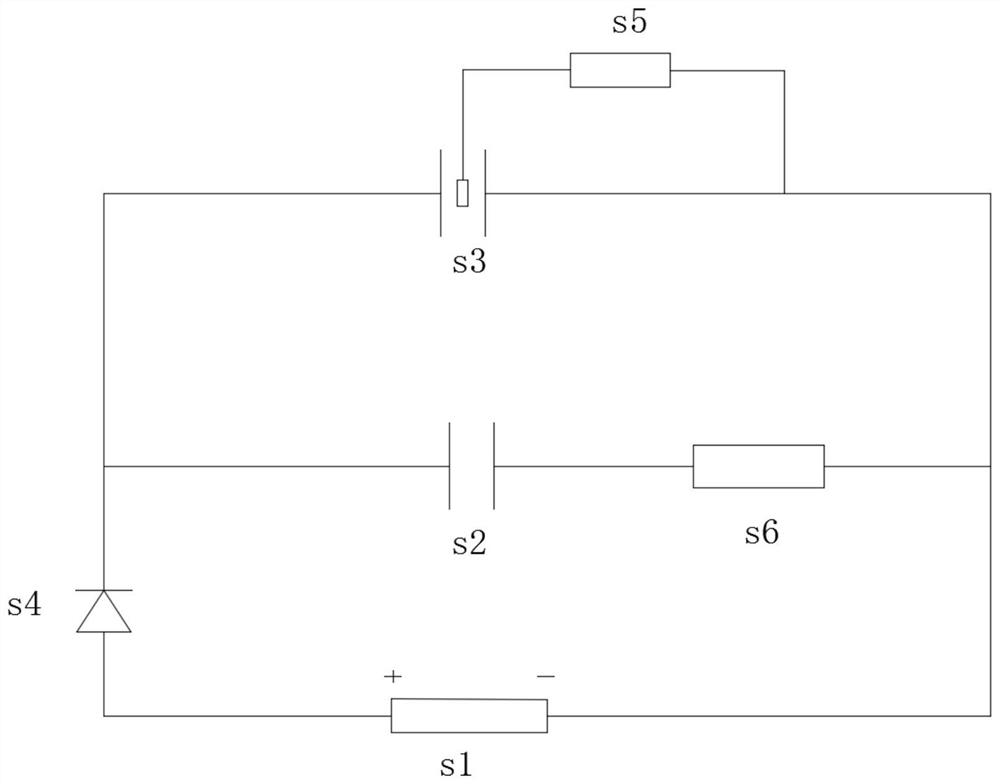

[0023] The buffer liquid adopts n-hexane liquid with low viscosity, and the gap between the pressure guide plate 6 and the side wall of the liquid chamber 5 is matched. The piezoelectric sheet 7 is not in contact with the top wall of the liquid chamber 5, and the piezoelectric sheet 7 in each horizontal plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com