Rectangular sealing strip and variable displacement vane pump

A sealing strip and vane pump technology, which is applied in the field of oil pumps, can solve problems such as unexpected variables, advanced variables, and inaccurate oil pump variables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

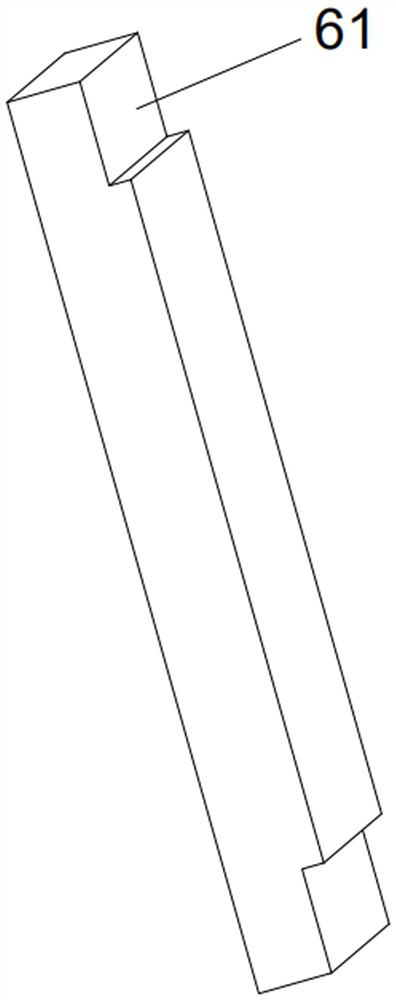

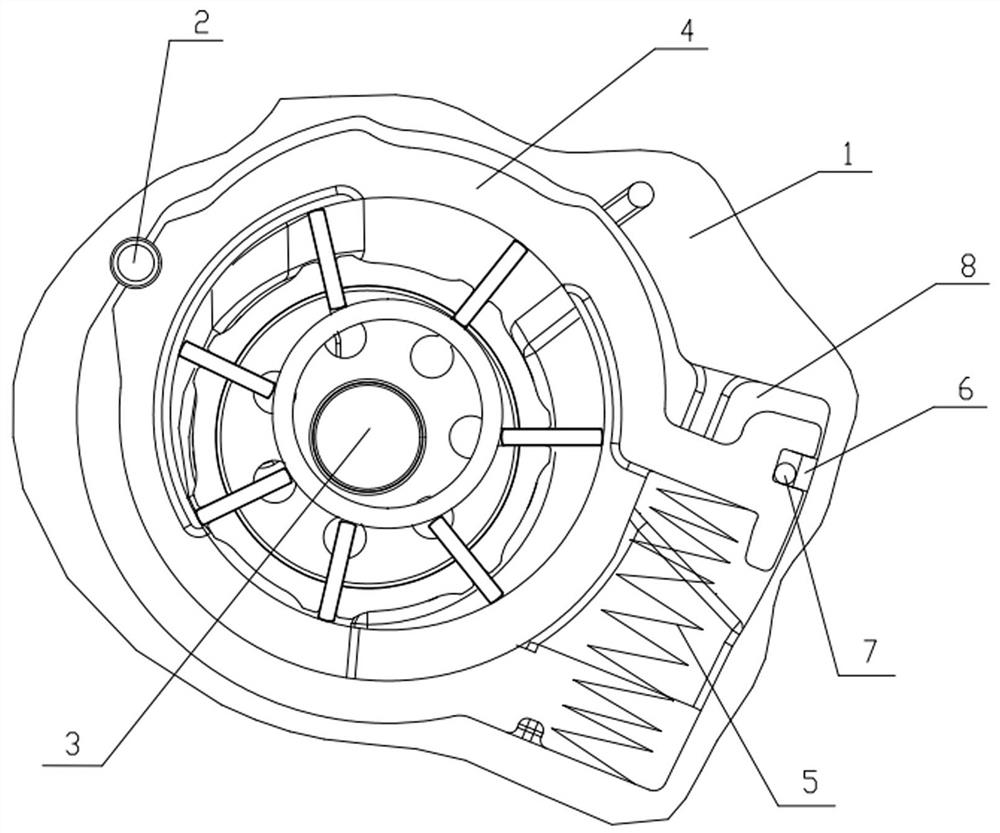

[0021] Such as figure 1 The shown rectangular sealing strip is used to be installed in the seal installation groove of the variable slider of the vane pump. The specific installation position is as follows: figure 2 As shown, notches 61 are provided on the same side of the upper and lower ends of the rectangular sealing strip.

Embodiment 2

[0023] Such as figure 1 , 2 As shown, a variable displacement vane pump includes a pump body 1, a rotating pin 2, a rotor 3, a variable slider 4, a variable spring 5, a rectangular sealing strip 6, and a sealing support 7. The pump body 1 and the variable sliding A variable control cavity 8 is provided between the blocks 4; the variable slider 4 is provided with a spring pressure block and a seal installation groove, and the seal support 7 and the rectangular sealing strip 6 are installed in the seal installation groove of the variable slider 4; the seal support The part 7 is a round rubber rod; the upper and lower ends of the rectangular sealing strip 6 are provided with notches 61 on the outward side.

[0024] Since the ends of the upper and lower ends of the rectangular sealing strip 6 are provided with gaps 61, the excess pressure oil in the variable control chamber 8 can pass through the gaps 61 and flow into the oil inlet chamber of the oil pump through the gap between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com