Friction-free air cylinder capable of adjusting air film gap

A frictionless cylinder and gap technology, applied in air cushion bearings, bearings, fluid pressure actuation devices, etc., can solve the problems of difficult processing, unadjustable air film gap, and easily limited use scenarios.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

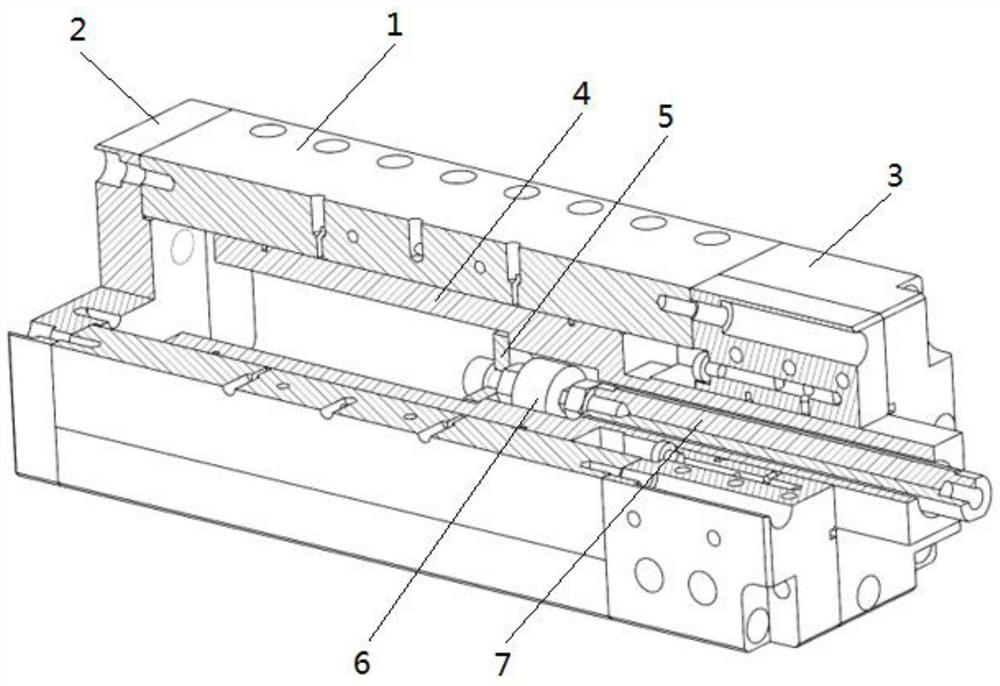

[0036] see Figure 1 ~ Figure 3 , a frictionless air cylinder with adjustable air film gap provided in this embodiment includes a cylinder barrel 1 and a first end cover 2 and a second end cover 3 respectively arranged at both ends of the cylinder barrel 1, and the cylinder barrel 1 has working The cavity 11 means that the whole inner cavity of the cylinder barrel 1 can be the working cavity 11 , or the inner cavity part of the cylinder barrel 1 can be used as the working cavity 11 . The working chamber 11 is provided with a piston assembly composed of the piston 4 and the piston rod 7, which means that the working chamber 11 is used for installing or assembling the piston assembly to achieve the purpose of forming the main body of the cylinder. It should be noted that the piston assembly can be in the form that both the piston 4 and the piston rod 7 can extend out of the working chamber 11 , or one of them, such as the piston rod, can extend out of the working chamber 11 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com