Pressure relief valve with overpressure protection function and corresponding mining layered pressure relief air bag retaining wall

A technology of overpressure protection and pressure relief valves, which is applied in the direction of ventilation valves, safety valves, balance valves, etc., and can solve problems such as inconvenient transportation, easy displacement, and additional air storage tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

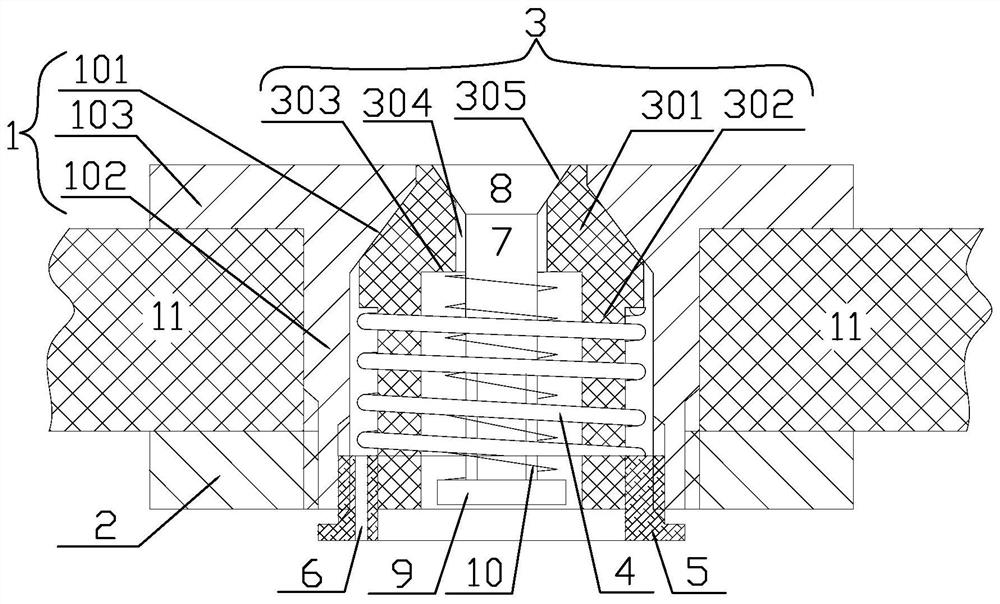

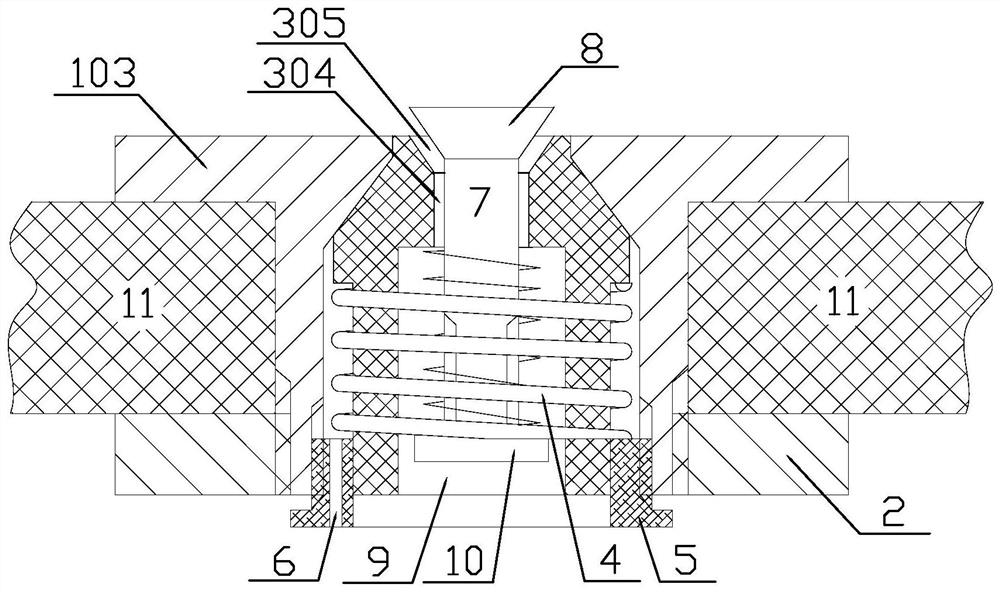

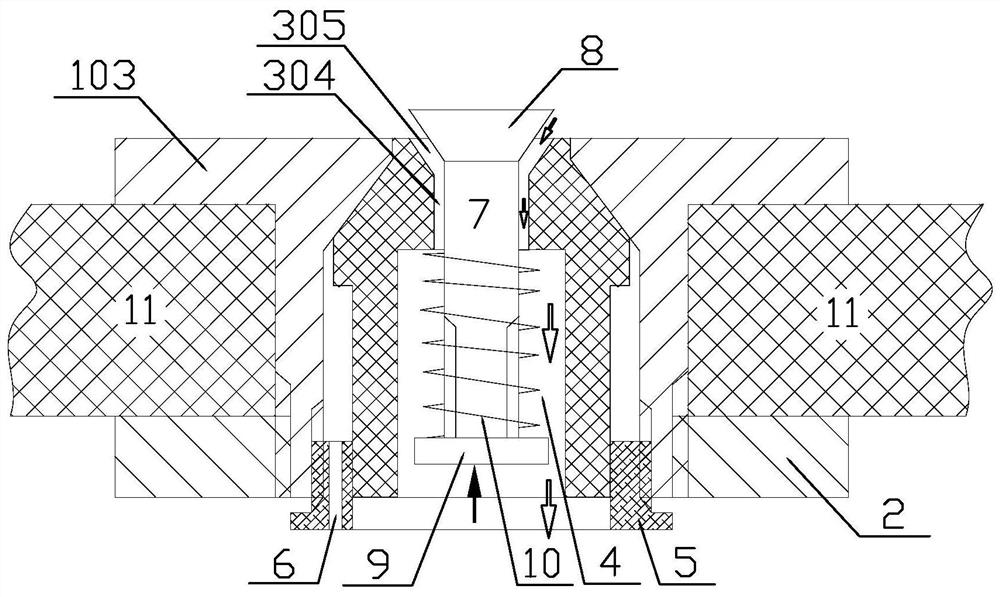

[0027] Implementation mode one: if Figure 1-4 As shown, the pressure relief valve with overpressure protection includes a valve seat 1, a fastening nut 2, a valve core 3, a coil spring 4 and an adjustable nut 5, and the valve seat 1 includes a tapered hole seat 101 and a solenoid 102, the inner end of the valve seat 1 is provided with a base plate 103, and the inside and outside of the screw tube 102 are respectively provided with internal threads and external threads, and the fastening nut 2 is screwed on the external thread of the screw tube 102, and the adjustable nut 5 is screwed on the inner thread of the spiral tube 102.

[0028] Described spool 3 comprises conical frustum 301 and guide post 302, and the conical center angle of the outer conical surface of described conical frustum 301 is identical with the conical central angle of the inner conical surface of described conical hole seat 101, and described guide post 302 is fixed On the large end axis of the cone trunc...

Embodiment approach 2

[0031] Implementation mode two: if Figure 5-6 As shown, the mine-used layered pressure-relief airbag retaining wall includes an airbag body 11, which is provided with an inflation valve 12 and a pressure relief valve 13, and the inner space of the airbag body 11 is divided into an upper air chamber 14 and a lower airbag body. The air chamber 15 is characterized in that: the upper air chamber 14 and the lower air chamber 15 are respectively provided with an inflation valve 12 and a pressure relief valve 13, and the pressure relief valves 13 of the upper air chamber 14 and the lower air chamber 15 are both described in the first embodiment Pressure relief valve with overpressure protection.

[0032] A water filling chamber 16 is also provided below the lower air chamber 15, and the water filling chamber 16 is provided with a water filling valve 17 and a pressure relief valve 13. pressure relief valve. Fixing holes 18 are respectively arranged on the sides of the upper air cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com