On-site explosive mixture automatic charging and safe detonating device and a charging and detonating method

A technology of mixing explosives and detonating devices, applied in blasting and other directions, can solve the problems of weakening of detonating effect of detonating cord, explosion of detonating cord or detonator explosive, damage of detonating cord, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

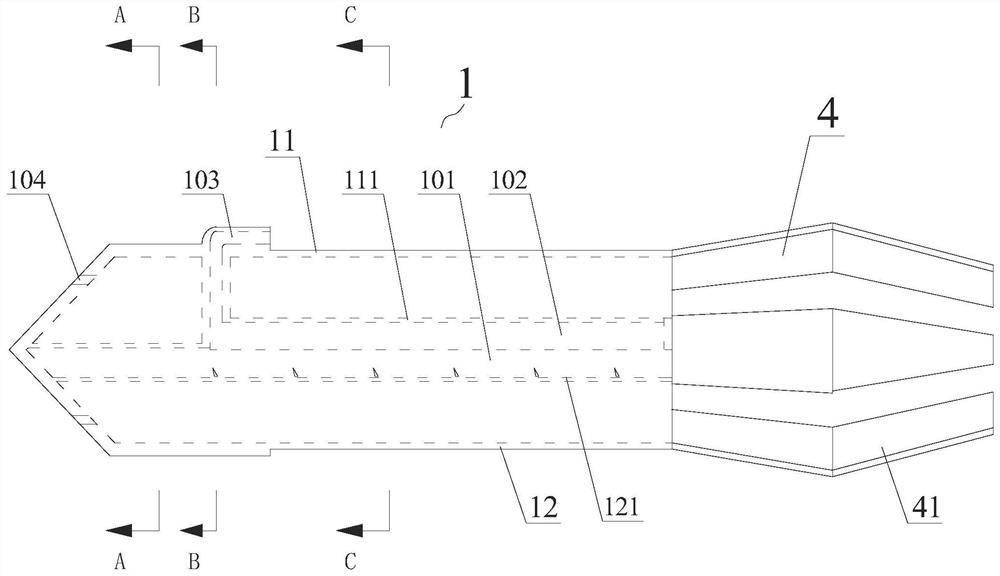

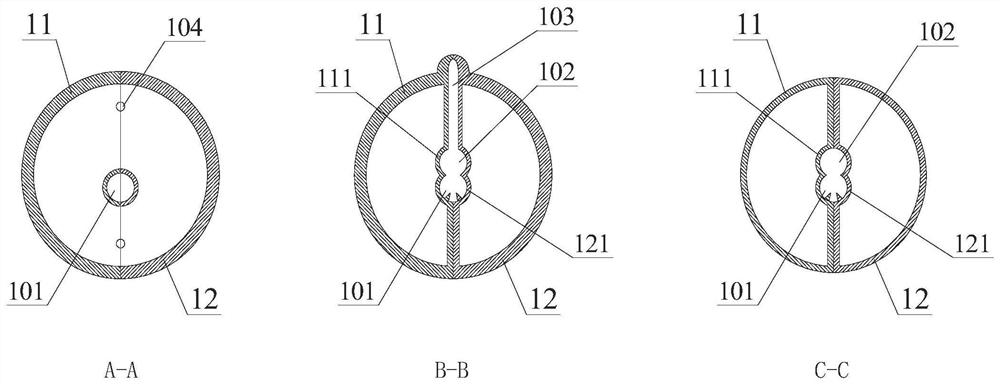

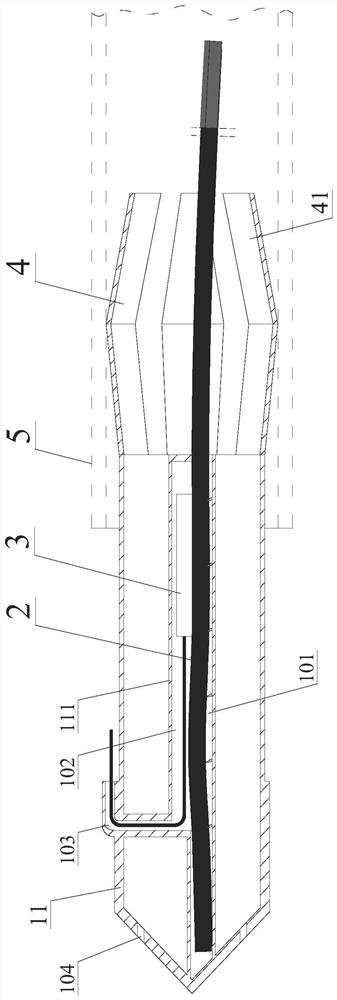

[0029] See attached Figure 1-3 As shown, the on-site mixed explosive automatic charge safety detonation device includes a safety protection main body 1, a detonating cord 2 and a detonator 3, and the safety protection main body 1 is provided with a detonating cord installation room 101 and a detonator installation room 102. The side of the protective body 1 is provided with a detonator lead wire hole 103 communicating with the detonator installation chamber 102, the detonating cord 2 is placed in the detonating cord installation chamber 101 and its tail extends to the rear end of the safety protection main body 1 The outside is mixed with the explosives filled in the blast hole, the detonator 3 is installed in the detonator installation chamber 102 and is tightly connected with the detonating cord 2, and the lead wire of the detonator 3 passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com