Sealing detection device for movement diaphragm capsule of diaphragm gas meter

A membrane gas meter and sealing detection technology, which is applied in the direction of detecting the appearance of fluid at the leakage point and using liquid/vacuum degree to measure the liquid tightness, etc., can solve the problem of gas leakage and sealing performance that do not meet the requirements of the core bellows , endangering human life and property safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

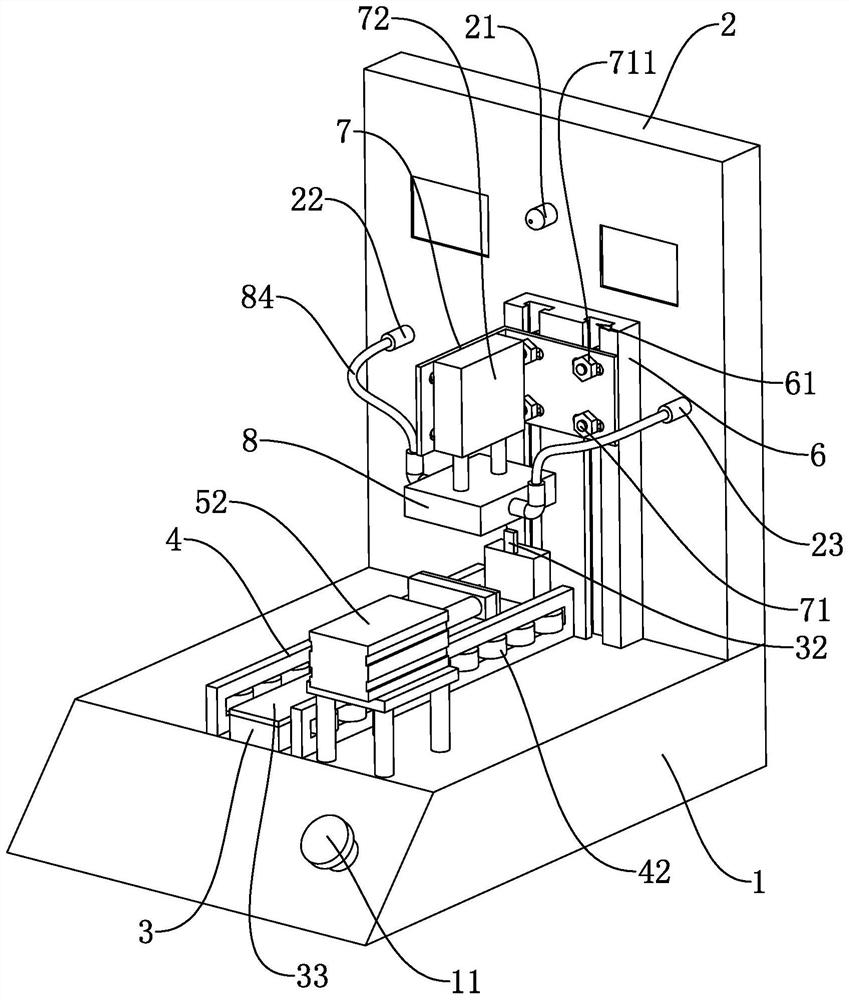

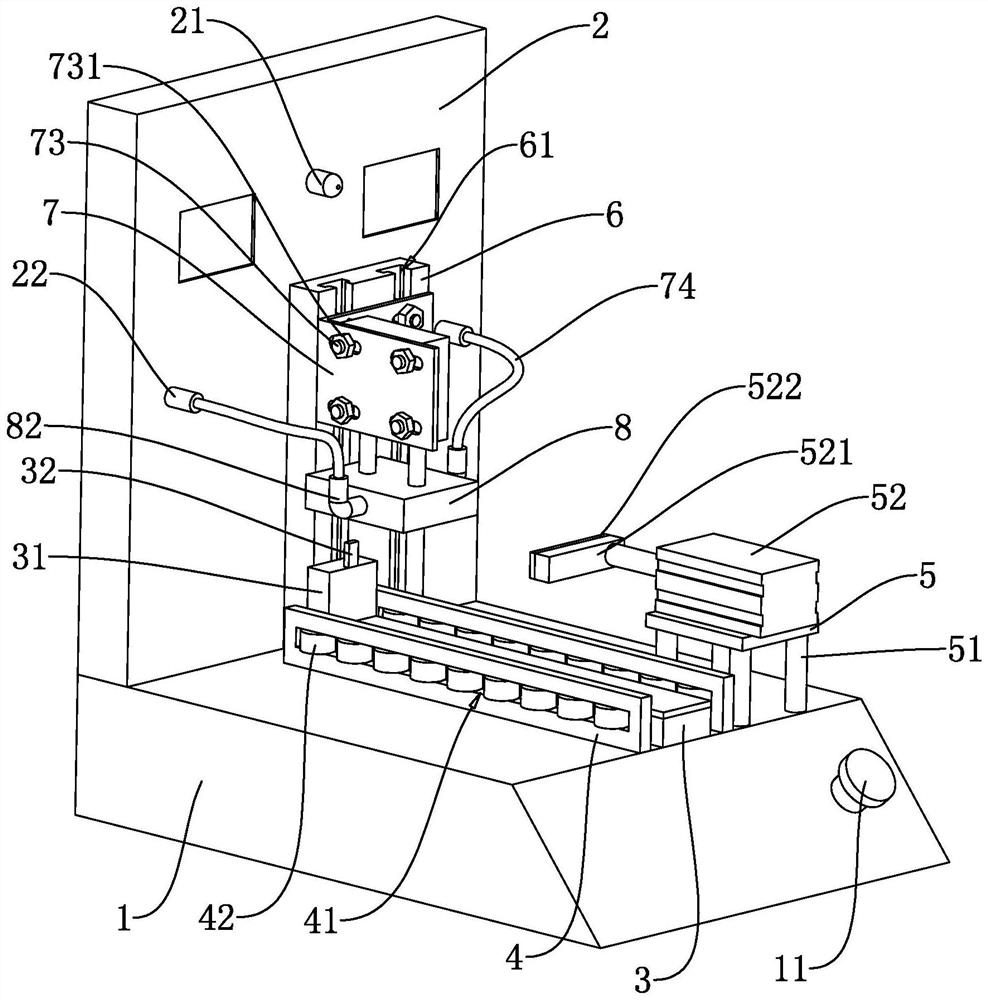

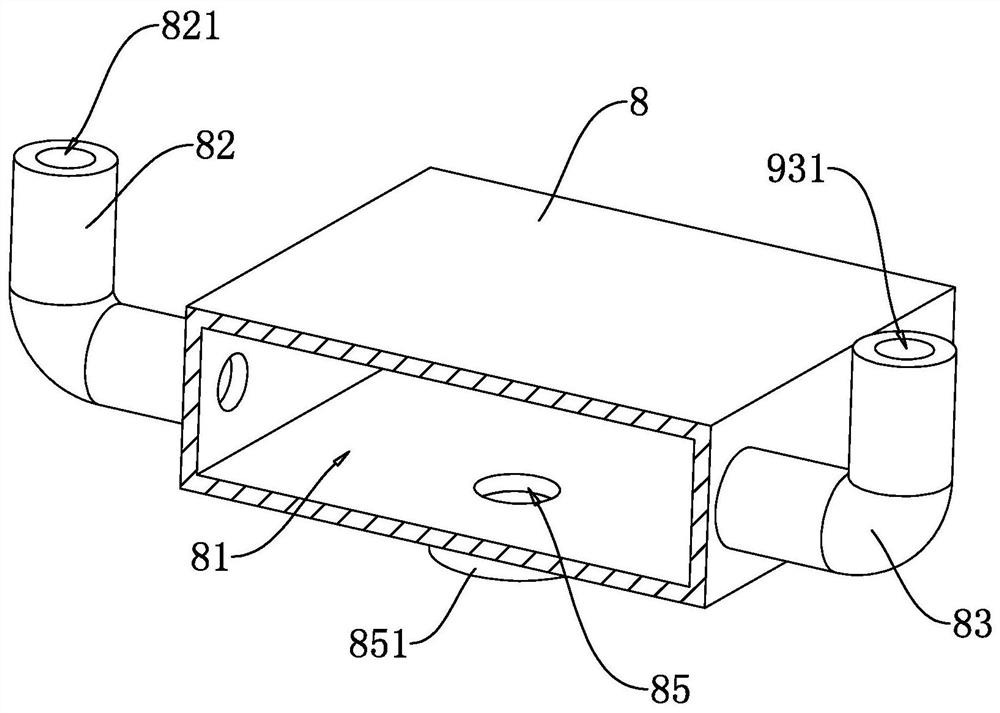

[0019] The following is attached Figure 1-3 The application is described in further detail.

[0020] The embodiment of the present application discloses a sealing detection device for a diaphragm box of a diaphragm gas meter.

[0021] refer to figure 1 A sealing detection device for a membrane box of a membrane gas meter, comprising a frame 1, the frame 1 is in the shape of a cuboid as a whole, and the length direction of the frame 1 is horizontally arranged, and one end of the length direction of the frame 1 is provided with a emergency Stop switch 11. Therefore, the convenience of closing the sealing detection device can be improved.

[0022] refer to figure 1 The side of the frame 1 in the longitudinal direction away from the emergency stop switch 11 is provided with a tightness detector 2 . The sealing detector 2 is provided with an indicator light 21 . A first connecting pipe 22 and a second connecting pipe 23 are arranged on the airtightness detector 2 , and both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com