Multi-process manufacturing system functional health state modeling method based on coupling operation factors

A technology for manufacturing systems and health status, applied in manufacturing computing systems, instruments, random CAD, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

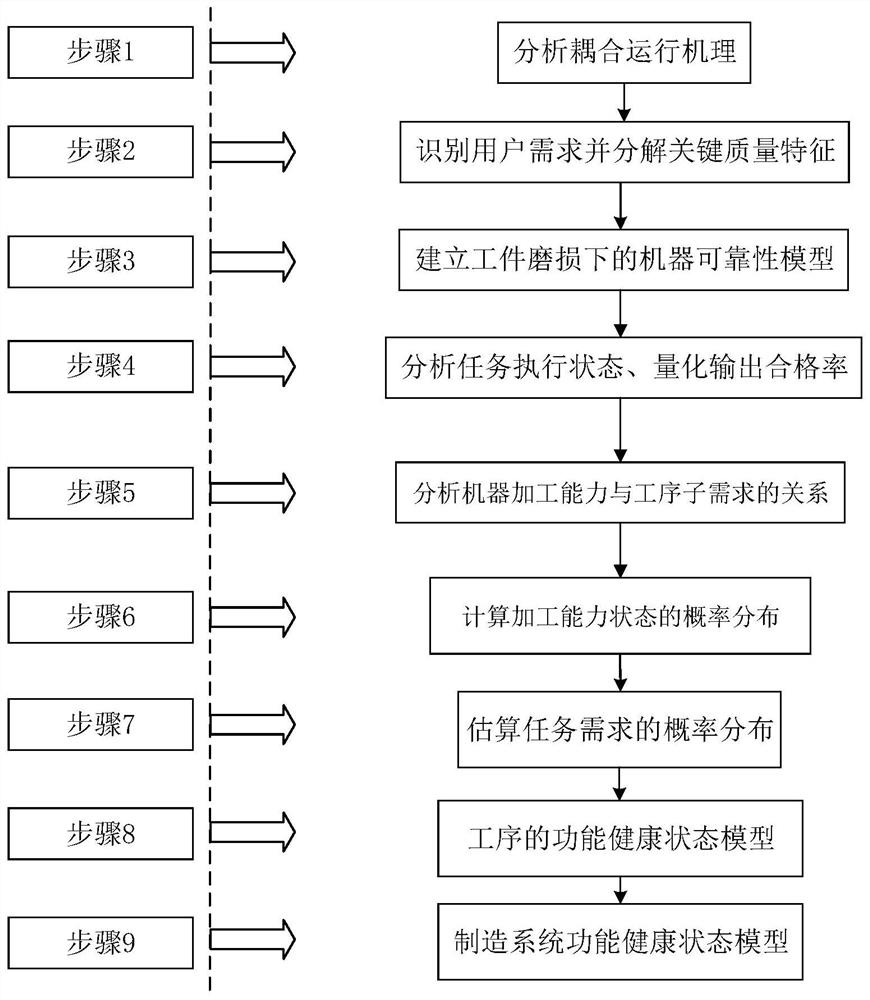

[0083] The present invention is a multi-process manufacturing system functional health state modeling method based on coupling operation factors, see figure 1 As shown, the steps are as follows

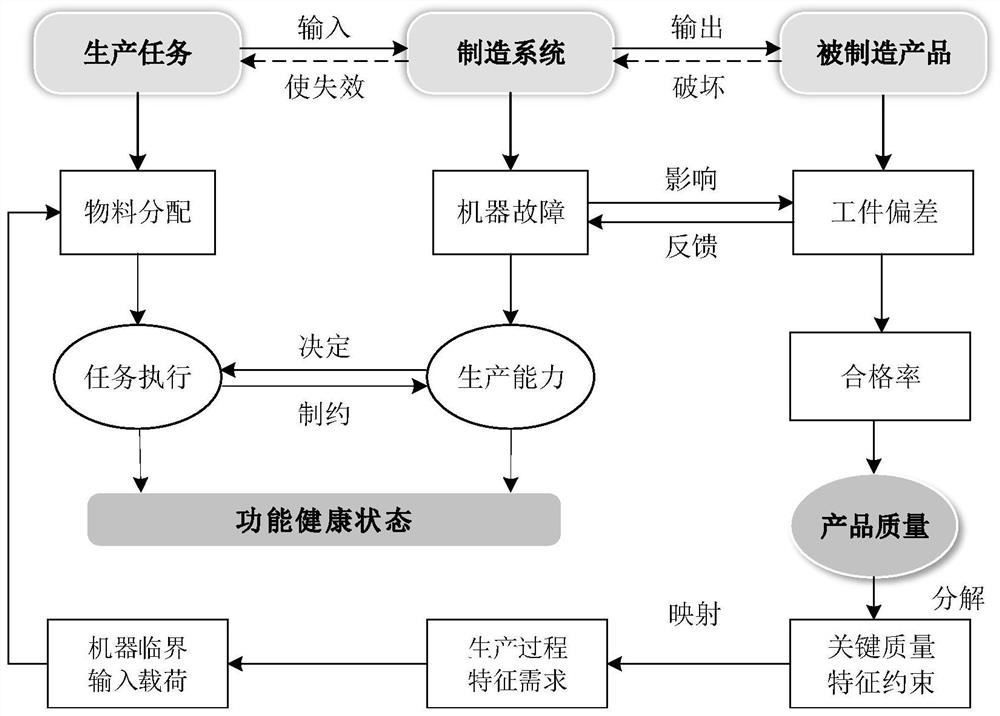

[0084] Step 1 Analyze the coupling operation mechanism of a ferrite phase shifting unit manufacturing system and its impact on functional health, such as figure 2 shown. The fragility of the ferrite phase shifting unit itself means that irresistible damage or dimensional deviation is very easy to occur during the production process. When a defective workpiece causes a failure of a downstream machine, it will significantly affect the machine performance and reduce the output pass rate . To compensate for the load pressure caused by increased scrap, the machines had to be run at higher levels of production capacity. This series of coupling effects is not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com