Tunnel advanced drilling geological refined forecasting method and application

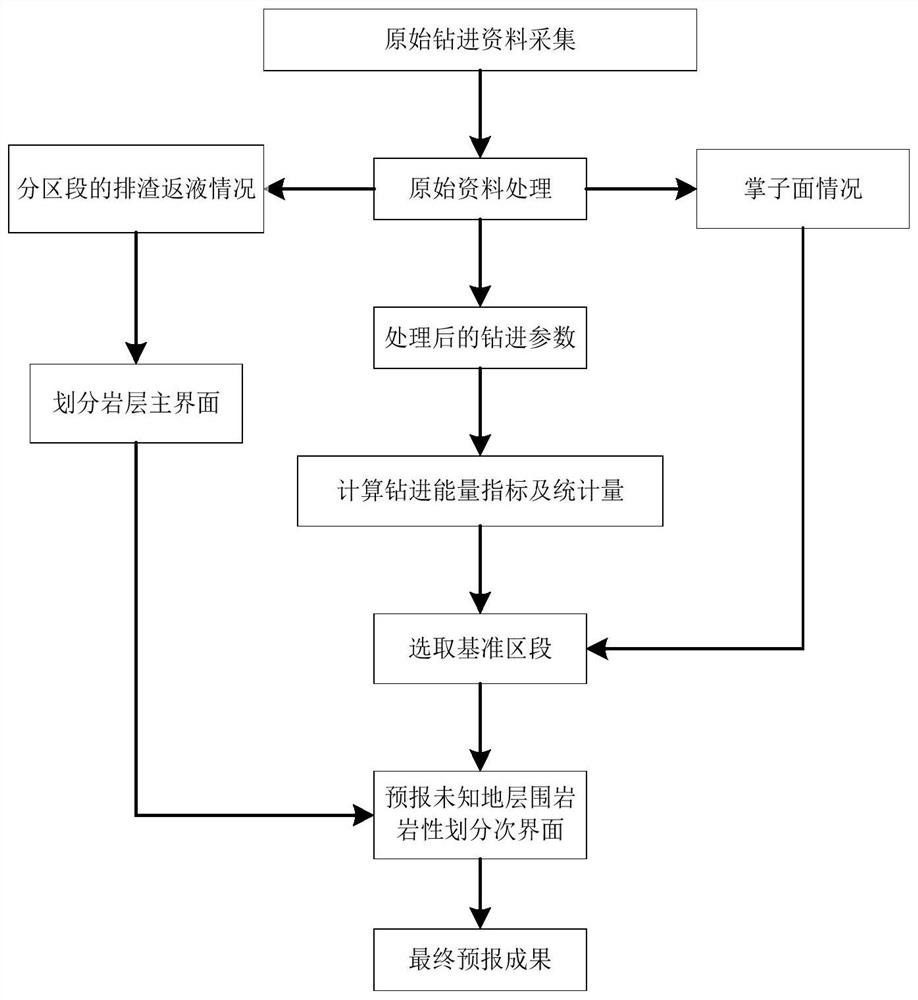

A tunnel and geological technology, applied in the field of tunnel geological survey, can solve the problems of inability to accurately predict the detailed characteristics of unknown strata, high misjudgment rate, and waste of drilling parameter response information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the given examples are only used to explain the present invention, and are not intended to limit the scope of the present invention.

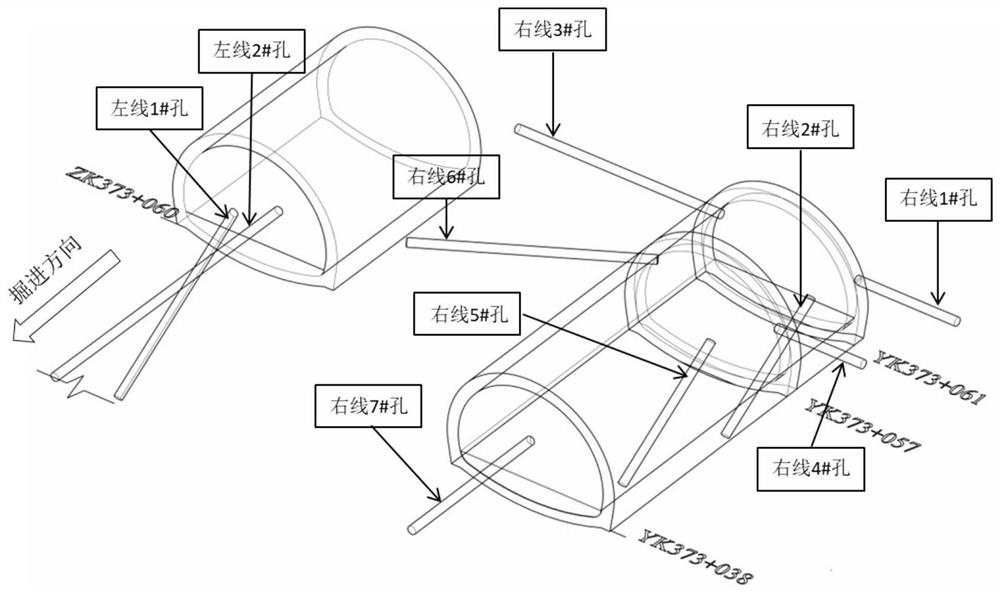

[0024] The C6-XP full-hydraulic crawler multifunctional drilling rig developed by Italian Casacolandi Company was used to carry out advanced drilling detection for the No. 2 tunnel in the lower row of the Du'an-Bama section of the Hezhou-Bama Expressway. When the left hole of the tunnel was excavated to the tunnel face ZK373+090, and the right hole was excavated to the tunnel face YK373+060, the clay mixed with rocks were respectively exposed to fill the karst cave. Collapse cavity karst cavity. The drilling method used in this drilling is the top drive hydraulic hammer type. Use the LUTZ drilling data acquisition system equipped on the drilling rig to collect the drilling parameters. The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com