High-strength steel sheet and method for manufacturing same

A technology of high-strength steel plate and manufacturing method, which is applied in the direction of manufacturing tools, coatings, furnace types, etc., and can solve problems such as reduced toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

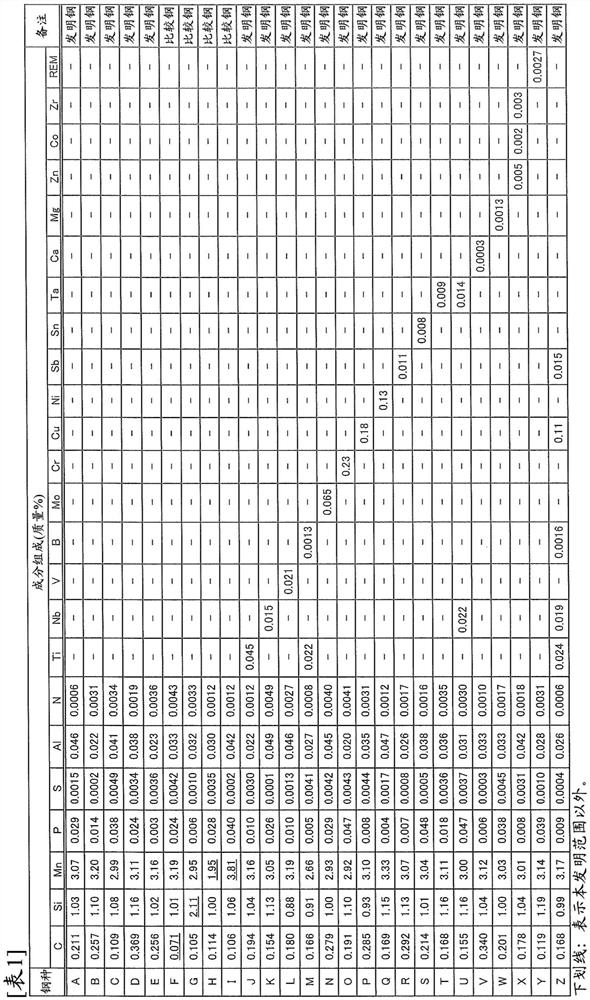

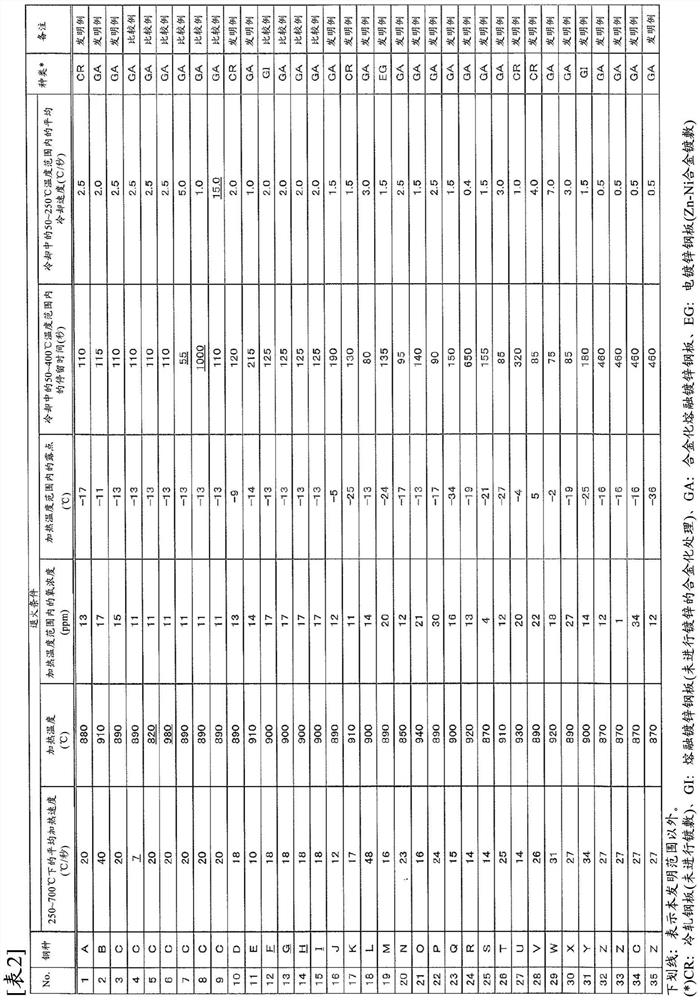

[0160] Steels having the composition shown in Table 1 with the balance being Fe and unavoidable impurities were melted in a converter, and steel slabs were produced by continuous casting. The obtained slab was heated, pickled after hot rolling, and then cold rolled.

[0161] Next, an annealing treatment was performed under the conditions shown in Table 2 to obtain a high-strength cold-rolled steel sheet (CR). In addition, a part of the high-strength cold-rolled steel sheet was subjected to a plating treatment to obtain a hot-dip galvanized steel sheet (GI), an alloyed hot-dip galvanized steel sheet (GA), an electrogalvanized steel sheet (EG), and the like. For the hot-dip galvanizing bath, in the case of GI, a zinc bath containing Al: 0.14 to 0.19% by mass is used, and in the case of GA, a zinc bath containing Al: 0.14% by mass is used, and the bath temperature is 470°C. Regarding the amount of plating, in the case of GI, it is 45 to 72 g / m equivalent to one side 2 (Double-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap