Orthosis with a fabric layer and a 3D printed layer

A 3D printing, 3D printer technology, applied in the direction of 3D object support structure, auxiliary operation of additional layers, manufacturing tools, etc., can solve problems such as inability to provide cost-effectiveness, high orthotics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In the various figures, identical parts are always provided with the same reference numerals, so they are usually also described only once. In particular, the drawings should be understood as representing various components or showing them in simplified form for greater clarity.

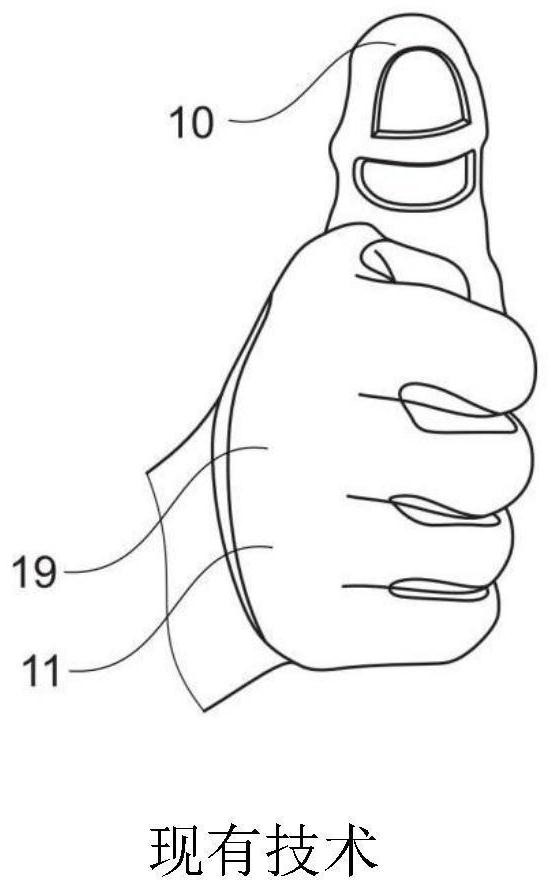

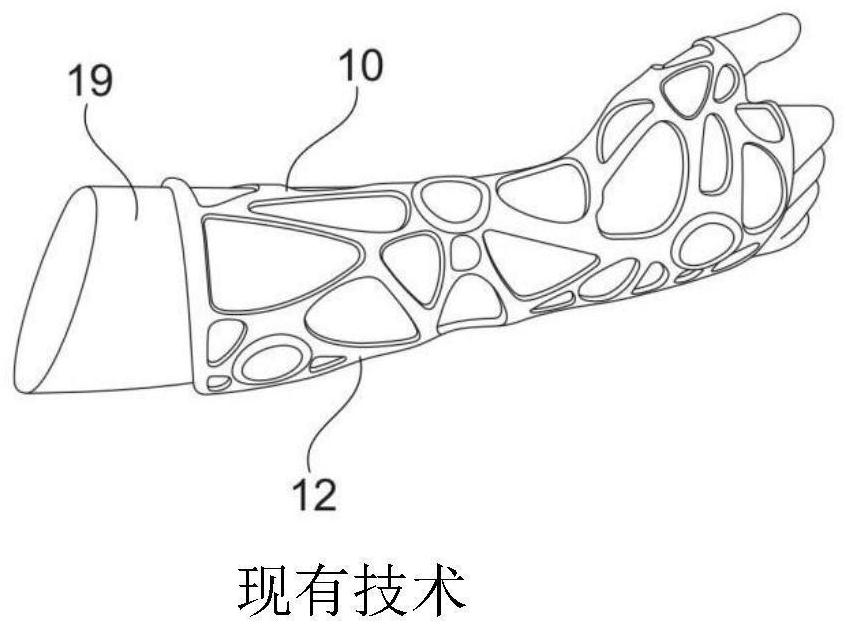

[0048] Figure 1a An orthosis 10 from the prior art is shown, which is designed as a thumb orthosis. The orthosis 10 is integrated into the glove 11 . The thumb orthosis protects the thumb joint of the user 19 during fitting operations that are performed very frequently and require a pressing movement of the thumb, for example. This reduces stress on the thumb joint. Figure 1b An orthosis 10 from the prior art is shown, which is designed as an exoskeleton 12 of the forearm and palm. Such an orthosis 10 can also be used for medical purposes, as well as an aid to assist the movements that are often performed especially in assembly operations, for example during continuous manufacturing on as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com