Novel efficient crushing equipment for quartz sand production

A crushing equipment and quartz sand technology, applied in the field of quartz stone crushing, can solve the problems of large energy consumption, heavy workload, and large volume of quartz sand production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

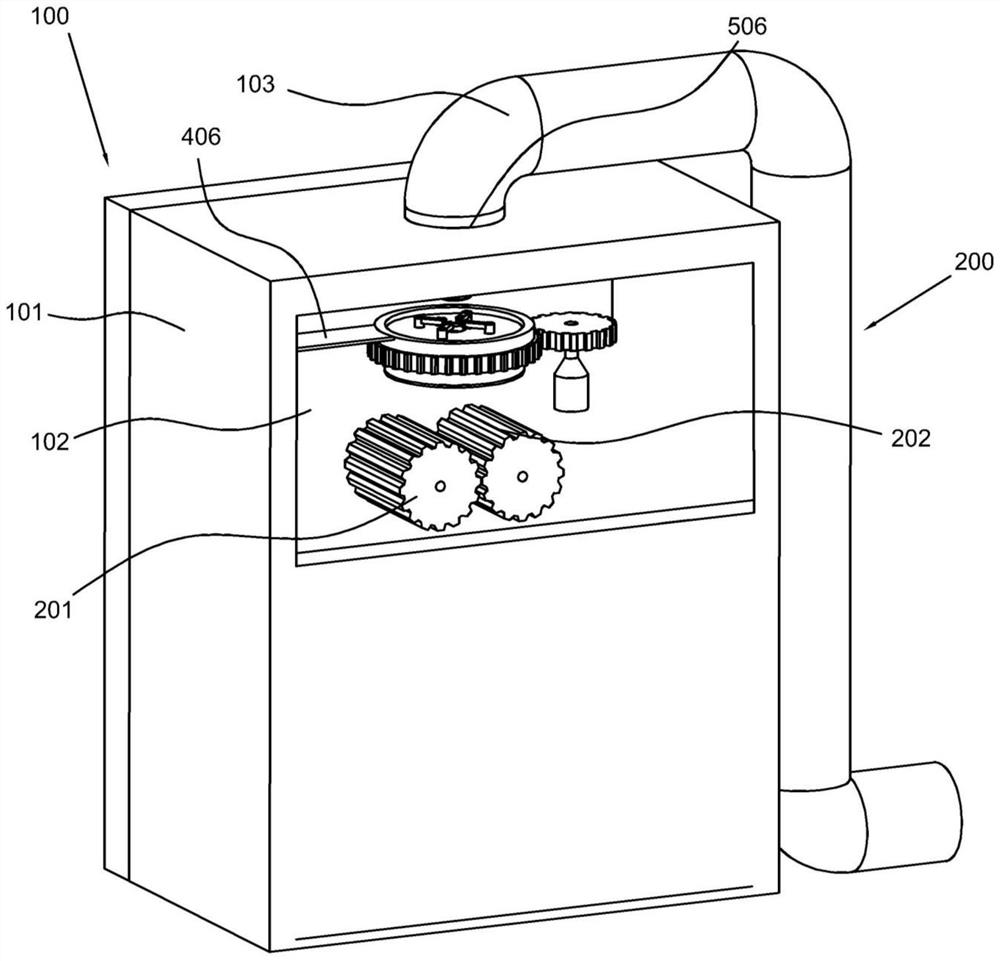

[0029] refer to figure 1 , a new type of high-efficiency crushing equipment for quartz sand production, including a load-bearing assembly 100, including a load-bearing body 101, a crushing space 102 opened in the load-bearing body 101, and a transportation pipeline 103 arranged on the upper end of the load-bearing body 101; the crushing assembly 200 includes Rotate the crushing wheel 201 connected in the crushing space 102, the crushing teeth 202 arranged on the outer surface of the crushing wheel 201, and the primary screen plate 203 arranged below the crushing wheel 201. There are two crushing wheels 201 and they are arranged close to each other; and, auxiliary The crushing assembly 300200 and the auxiliary crushing assembly 300200 are arranged on the upper end of the crushing assembly 200 .

[0030] Specifically, the main body of the present invention includes a bearing assembly 100. In this embodiment, the bearing assembly 100 includes a bearing body 101. The bearing body ...

Embodiment 2

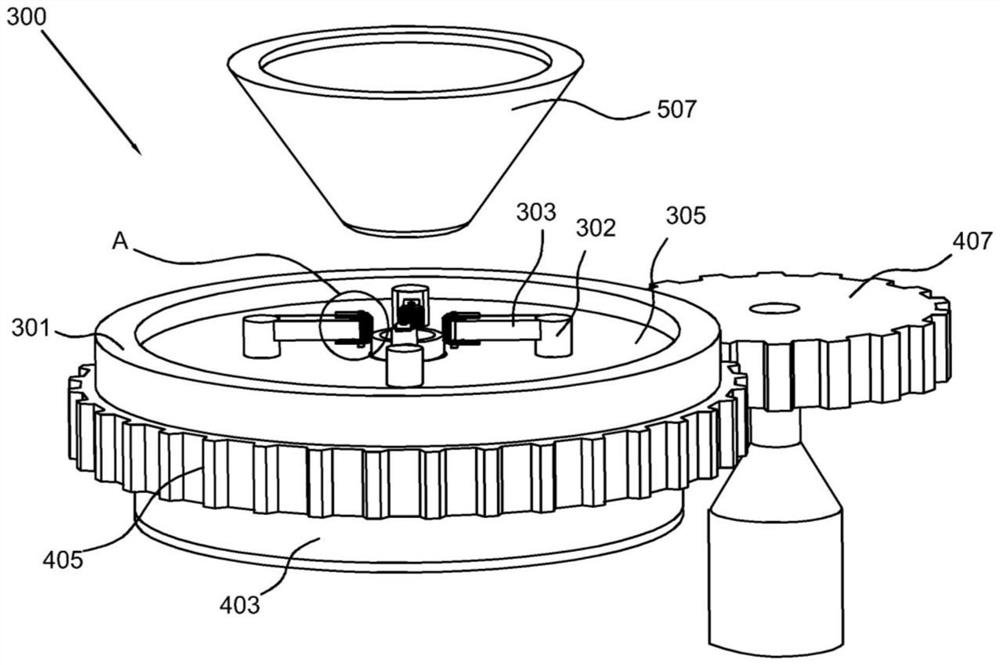

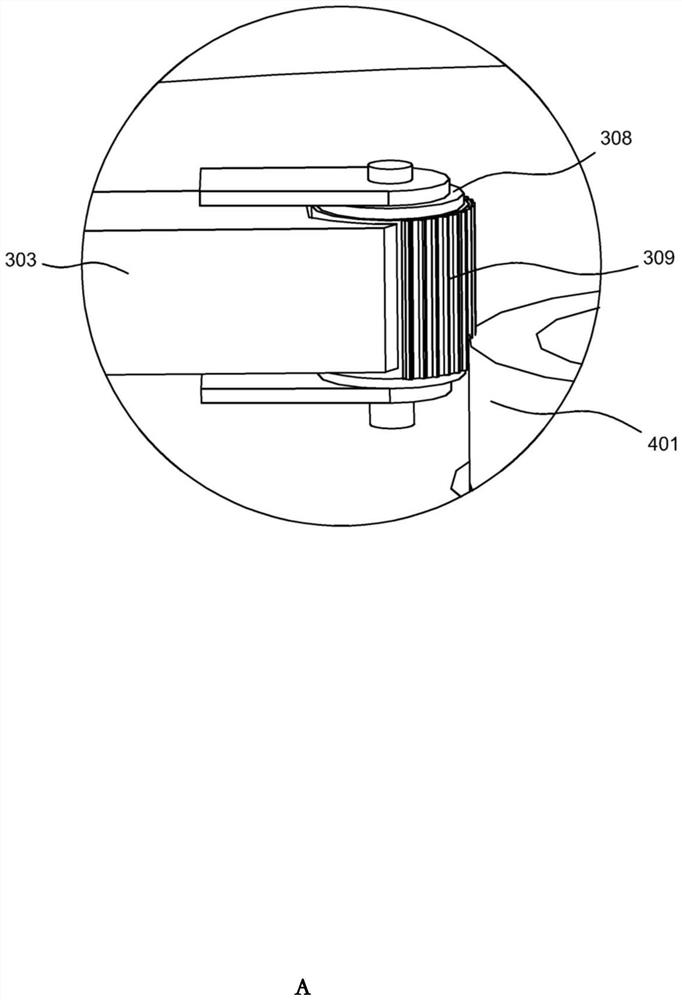

[0035] refer to Figure 1-4, This embodiment is different from the first embodiment in that: the auxiliary crushing assembly 300200 includes a rotating disk 301 arranged in the crushing space 102, several rotating rods 302 rotatably connected in the rotating disk 301, and one end of the rotating rod 302 The crushing rod 303 and the centrifugal rod 304 arranged at the other end of the rotating rod 302, wherein, the rotating disk 301 is fixed with an isolation plate 305, and the separating plate 305 divides the rotating disk 301 into an outer space and an inner space, and the crushing rod 303 is in the outer space In the inner space of the centrifugal rod 304, a through hole 306 is opened in the center of the rotating disk 301, and the end position of the crushing rod 303 is rotatably connected with a roller 308. The crushing tooth 309 is covered with a silicon knife shell, and a receiving column 400 is connected to the hole 306 by sliding in the vertical direction. The upper en...

Embodiment 3

[0044] refer to Figure 5 This embodiment is different from the above embodiments in that: the primary sieve plate 203 is provided with a number of first filter holes 503, the primary sieve plate 203 is slidably connected with a matching sieve plate 505, and the matching sieve plate 505 is provided with a second filter hole. hole 504, the first filter hole 503 aperture is smaller than the second filter hole 504, the side walls of the primary sieve plate 203 and the matching sieve plate 505 are equipped with electric cylinders, and the electric cylinders are connected to the primary sieve plate 203 or the matching sieve plate 505 With telescoping sleeve.

[0045] Specifically, a number of first filter holes 503 are opened on the primary sieve plate 203, and then a matching sieve plate 505 is slidably connected to the primary sieve plate 203, and the size of the matching sieve plate 505 is consistent with the size of the primary sieve plate 203 , and a second filter hole 504 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com