A kind of assembly mechanism of led lamp

A technology of LED lamps and assembly mechanisms, which is applied to devices for coating liquid on the surface, connecting components, mechanical equipment, etc., can solve the problems of limited efficiency of LED lamp processing, increased production costs, inconvenience, etc., to ensure the solidification effect and Efficiency, production cost reduction, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

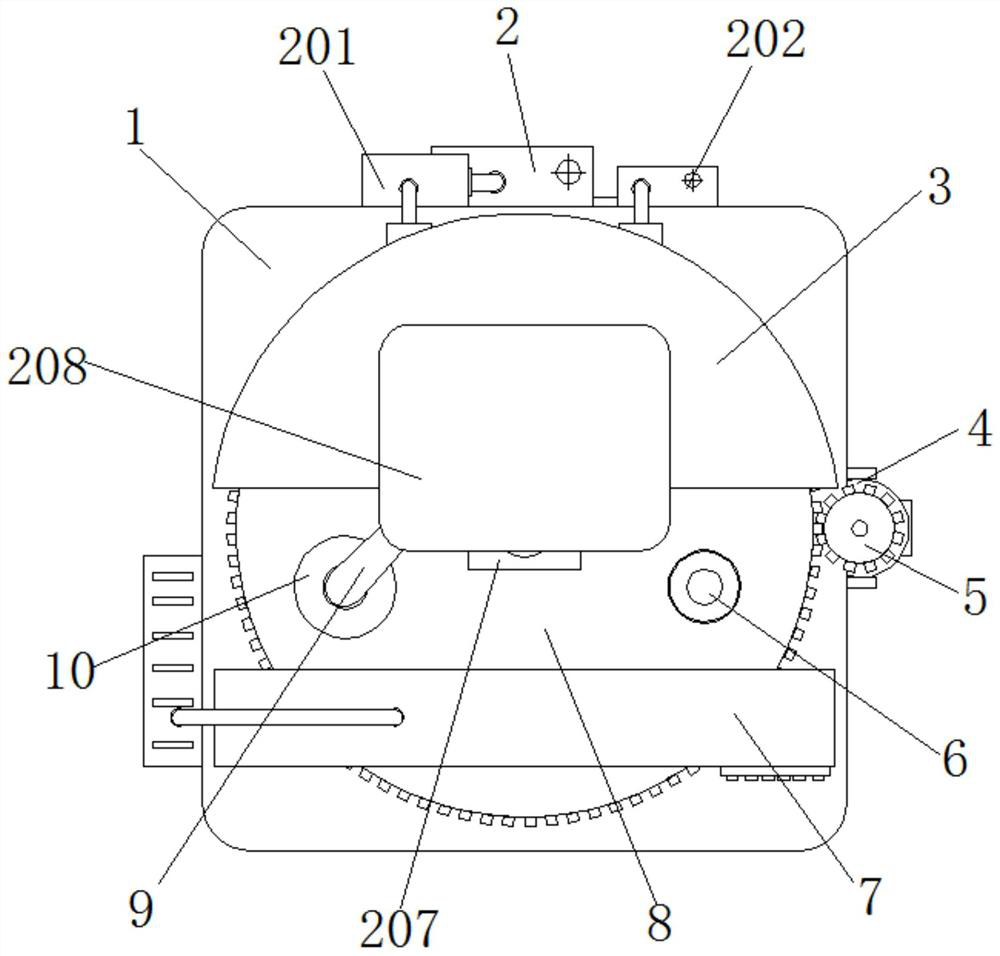

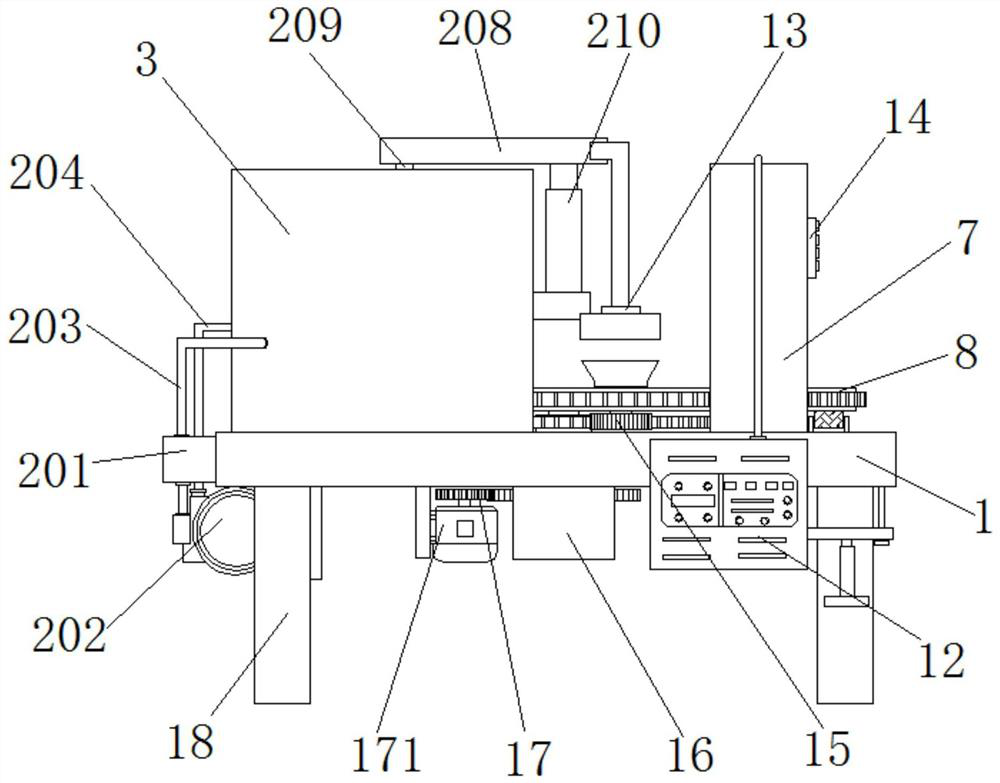

[0043] Example 1, such as Figure 1-7 As shown, when it is necessary to glue the edge position of the top of the lamp installation head, manually put the lamp installation heads into the interior of the placement groove 6 in groups, and control the rotation of the second servo motor 171 through the control panel 14, and the second The servo motor 171 drives the first installation pipe 174 to rotate through the cooperation of the first gear 176 and the second gear 175, and the first installation pipe 174 drives the second installation pipe 28 to rotate through the cooperation of the third gear 172 and the fourth gear 15, thereby Drive the placement groove 6 to rotate, and after the lamp installation head is placed into the placement groove 6 and gets stuck inside, control the first electric push rod 19 to elongate, so that the output end of the injection nozzle 20 is close to the edge position of the top of the lamp installation head, and then pass The glue supply device 12 sen...

Embodiment 2

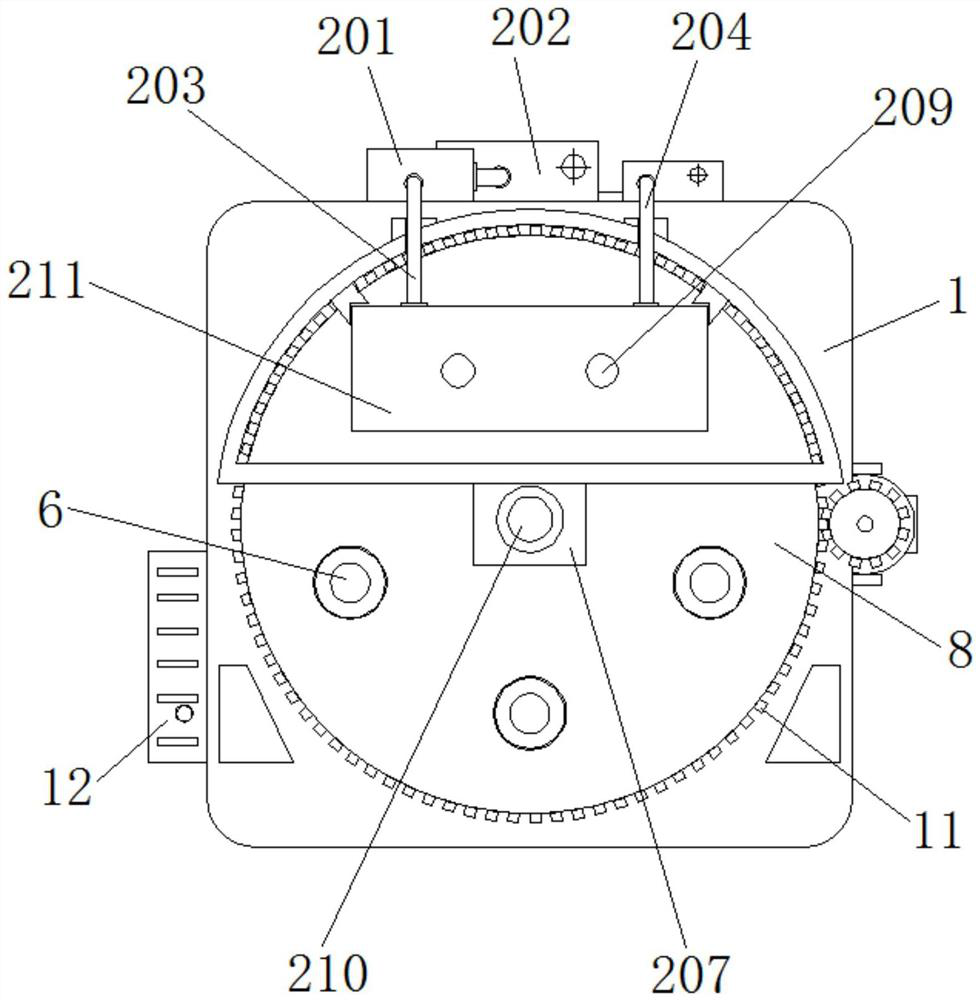

[0044] Example 2, such as figure 1 , 2 , 3, 4, 5, 6 and 8, when it is necessary to accelerate the solidification of the glue, when the lamps on one group of placement grooves 6 move to the directly below the inner annular warehouse 206, the electric lifting rod 210 is controlled to shorten, so that the two groups of annular The warehouse 206 descends, and the lamps pass through the inner circle of the annular warehouse 206 until the inner circle of the annular warehouse 206 moves to the position where there is glue on the connection between the lampshade and the lamp installation head, and then the electric heating tube 205 is controlled to energize to generate heat. The air pump 202 blows the heat generated by the electric heating tube 205 into the interior of the first group of annular chambers 206 through the air outlet pipe 203, and uses the through holes in the inner ring of the annular chambers 206 to blow the hot air to the glue, so that the glue is accelerated to solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com