Sign board gluing process

A plate and marking technology, applied to the surface coating liquid device, coating, etc., can solve the problem of high cost, achieve low cost, fast speed, and improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

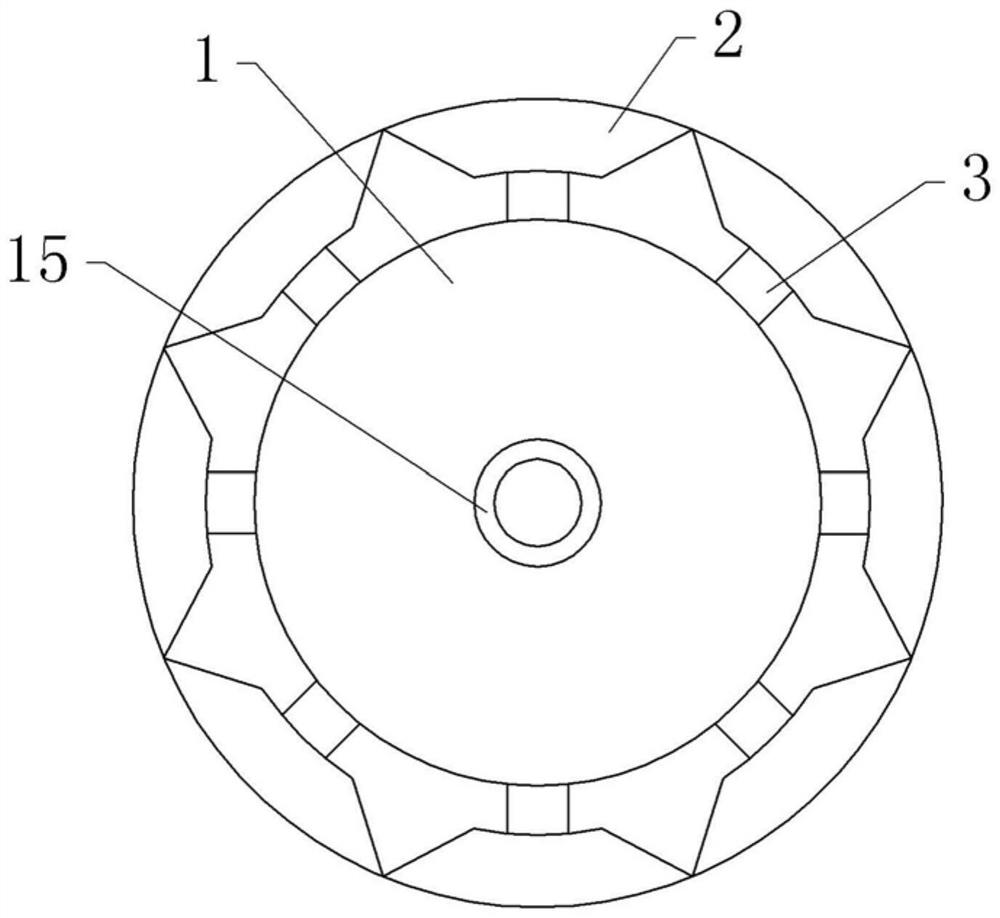

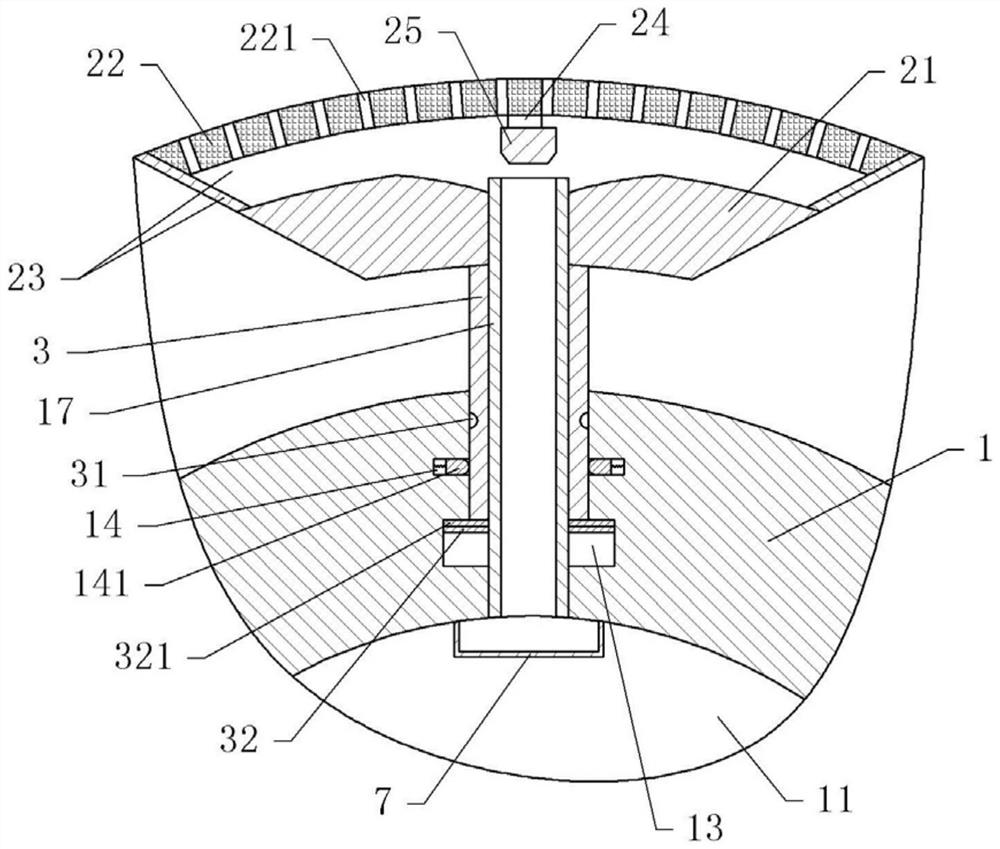

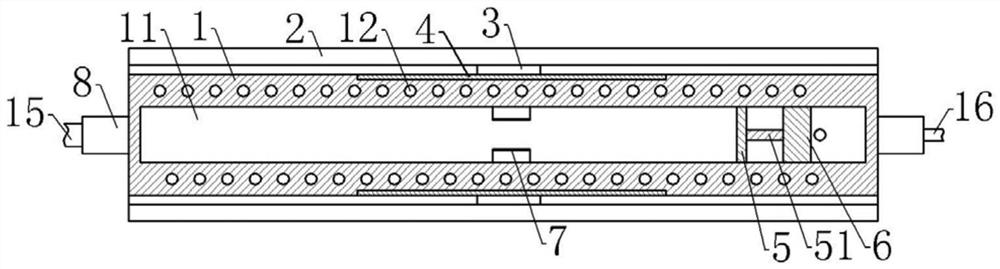

[0040] To identify the gluing process of the board, use the rubber roller to complete the coating of the glue solution. The rubber roller includes a roller body 1 and a plurality of glue blocks 2 wrapped outside the roller body 1. The number of glue blocks 2 can be based on actual needs To set, select 8 blocks in this embodiment. The gluing blocks 2 are all arc-shaped, and the 8 gluing blocks 2 are sequentially spliced into a cylindrical shape wrapped around the roller body 1 .

[0041] The rubberized blocks 2 all include an inner mounting block 21 and an outer rubberized layer 22, and also include a deformation layer 23 between the mounting block 21 and the rubberized layer 22, and the deformations on the left and right sides of the mounting block 21 and the rubberized layer 22 Layer 23 is a thin metal sheet. In the present embodiment, a copper sheet with a thickness of 2 mm is used. Therefore, when the rubber block 2 moves toward the inner side of the roller body 1, the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com