Screening device with detection mechanism for fluorescent powder waste

A technology of detection mechanism and screening device, applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems of waste of rare earth resources, uneven size of phosphor waste, large space for transportation, etc., and achieves high specification uniformity. , convenient for secondary processing, and the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

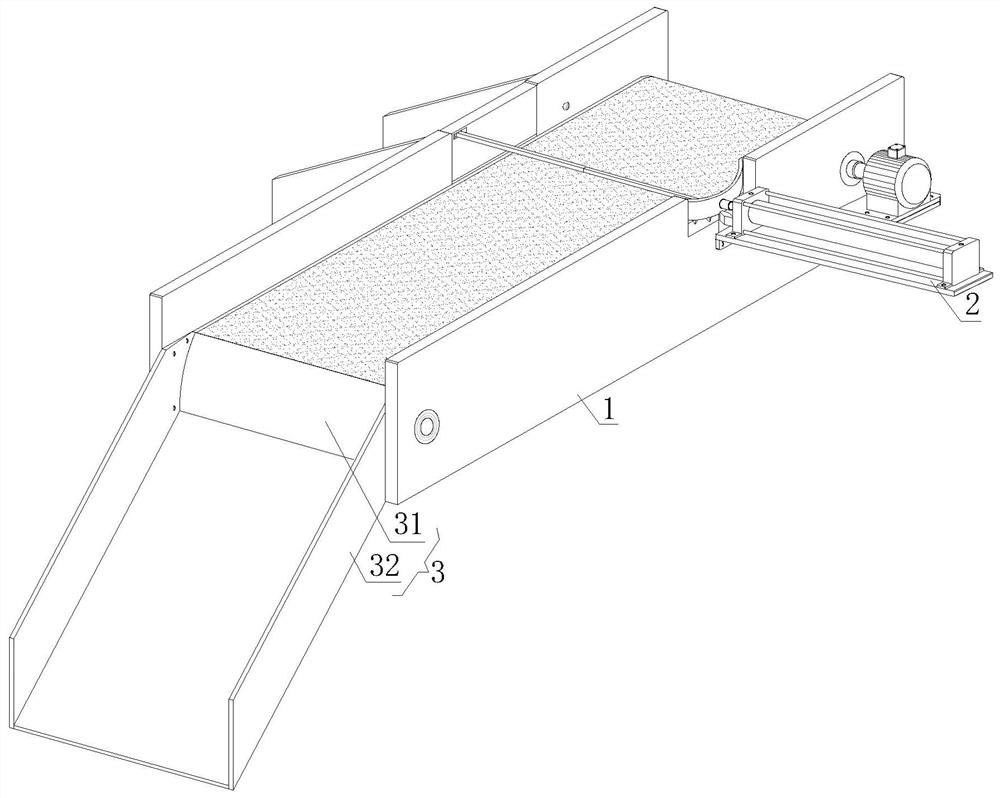

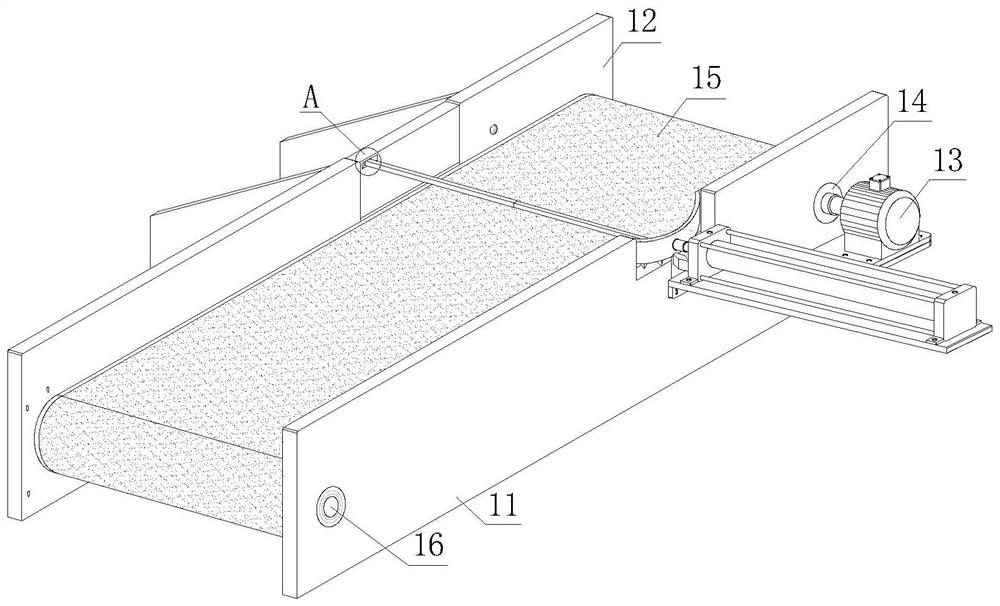

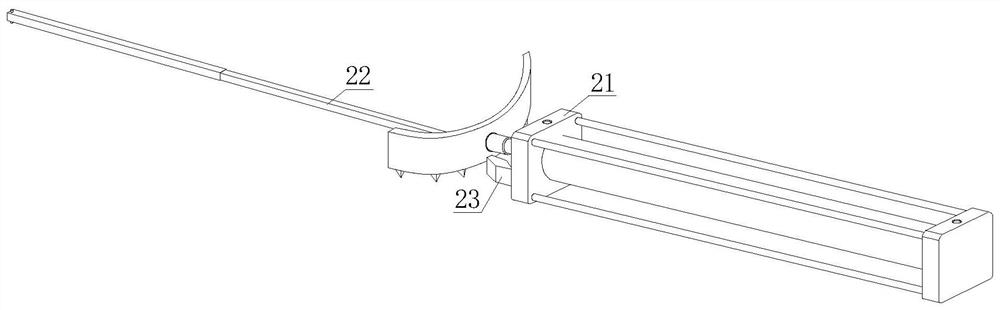

[0032] see Figure 1-2, a screening device with a detection mechanism for fluorescent powder waste, comprising a detection conveying mechanism 1, a screening mechanism 2 and a material guide mechanism 3, the screening mechanism 2 is arranged on the upper end of the detection conveying mechanism 1, and the material guide mechanism 3 is arranged on Detect the output end of the conveying mechanism 1. The detecting conveying mechanism 1 includes a mounting plate 11, a detecting connecting plate 12, a servo motor 13, a driving shaft 14, a conveyor belt 15 and a driven shaft 16. The servo motor 13 is arranged on one side of the mounting plate 11 One end of the drive shaft 14 is movably connected to one end on one side of the mounting plate 11, and the other end of the drive shaft 14 is movably connected to one end on one side of the detection connection plate 12. The detection connection plate 12 includes a sensor 121, a hinge 122, a splash-proof plate 123 and miscellaneous guide pl...

Embodiment 2

[0038] see Figure 1-2 , a screening device with a detection mechanism for fluorescent powder waste, comprising a detection conveying mechanism 1, a screening mechanism 2 and a material guide mechanism 3, the screening mechanism 2 is arranged on the upper end of the detection conveying mechanism 1, and the material guide mechanism 3 is arranged on Detect the output end of the conveying mechanism 1. The detecting conveying mechanism 1 includes a mounting plate 11, a detecting connecting plate 12, a servo motor 13, a driving shaft 14, a conveyor belt 15 and a driven shaft 16. The servo motor 13 is arranged on one side of the mounting plate 11 One end of the drive shaft 14 is movably connected to one end on one side of the mounting plate 11, and the other end of the drive shaft 14 is movably connected to one end on one side of the detection connection plate 12. The detection connection plate 12 includes a sensor 121, a hinge 122, a splash-proof plate 123 and miscellaneous guide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com