Laser welding equipment for aluminum plates

A laser welding and equipment technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of difficult to solve the double-sided welding of profiles, low product flatness, low degree of automation, etc., to achieve high flatness, The effect of automatic welding process and great versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

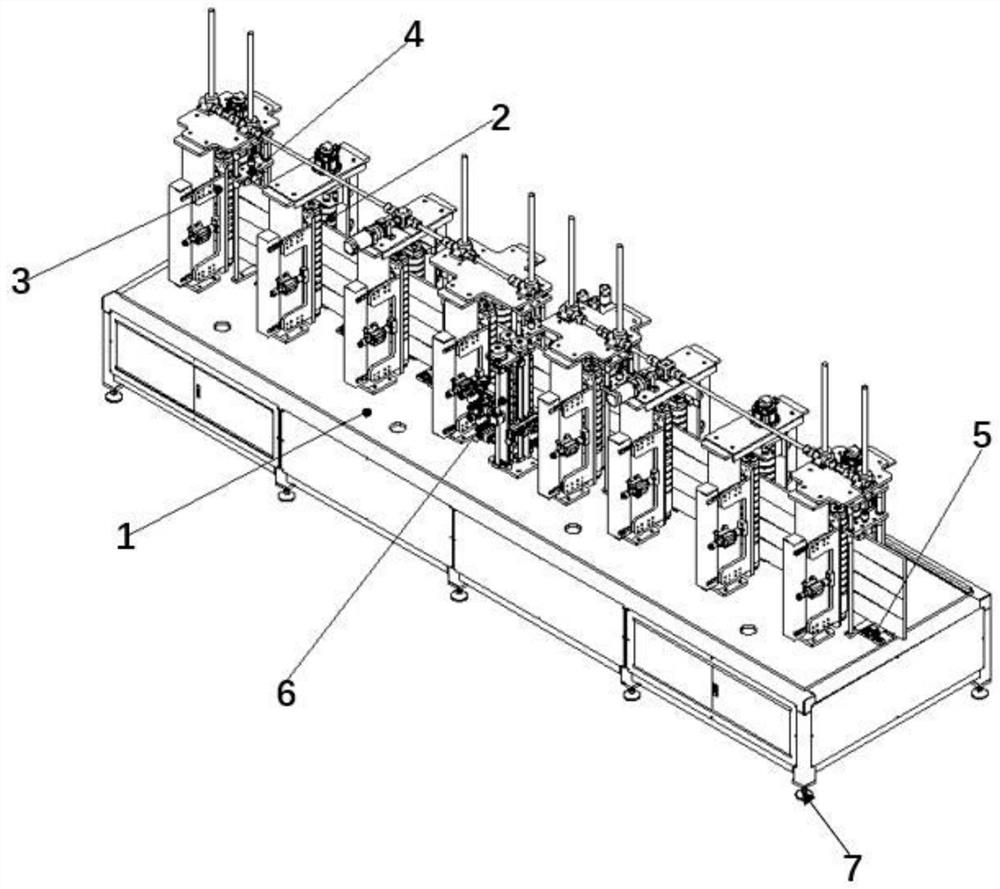

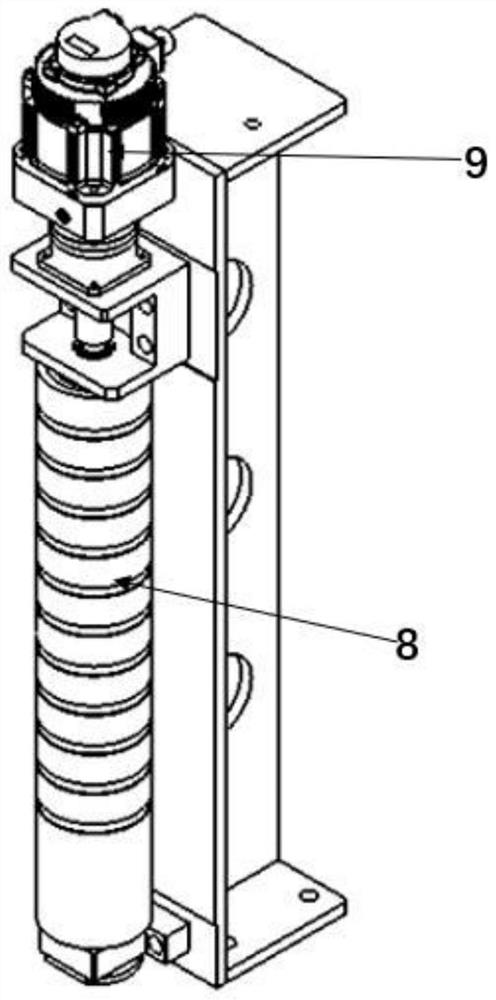

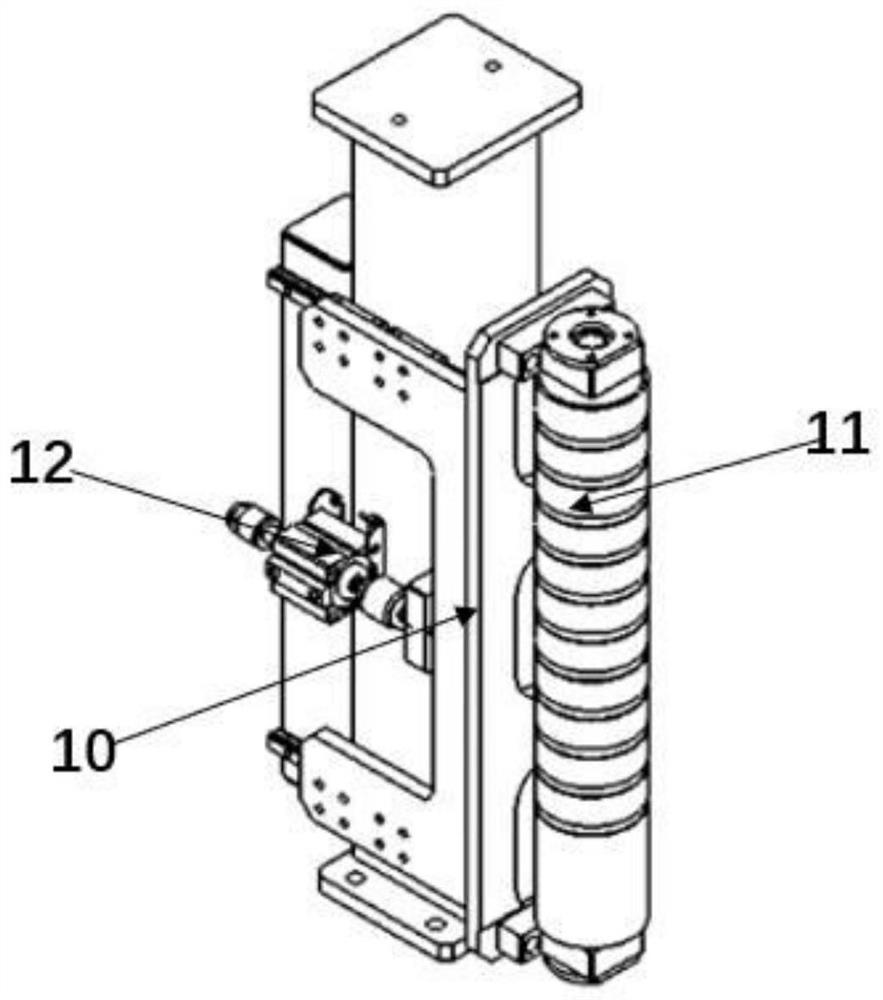

[0021] Such as Figure 1-6 As shown, a laser welding equipment for aluminum plate includes a main frame 1, a power roller mechanism 2, a side push driven roller mechanism 3, a lower pressing mechanism 4, a bottom idler mechanism 5 and a laser adjustment mechanism 6. The middle part of the right end of the top surface of the main frame 1 is fixedly equipped with a bottom idler mechanism 5. The bottom idler mechanism 5 is a driven mechanism, which adopts a unified standard part to ensure the height consistency of the bottom surface. The top front and back of the main frame 1 Several side push driven roller mechanisms 3 and several power roller mechanisms 2 are respectively equidistantly installed at both ends, and the tops between the side push driven roller mechanisms 3 and the power roller mechanisms 2 are fixedly installed with For the lower pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com