Head groove edge-grinding machine

An edger and head technology, which is applied to machine tools, grinders, and grinding/polishing equipment suitable for grinding the edges of workpieces, can solve the problems of affecting the appearance quality of containers, high cost, and difficulty in guaranteeing the groove size. , to achieve the effect of good groove geometry, improved service life and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

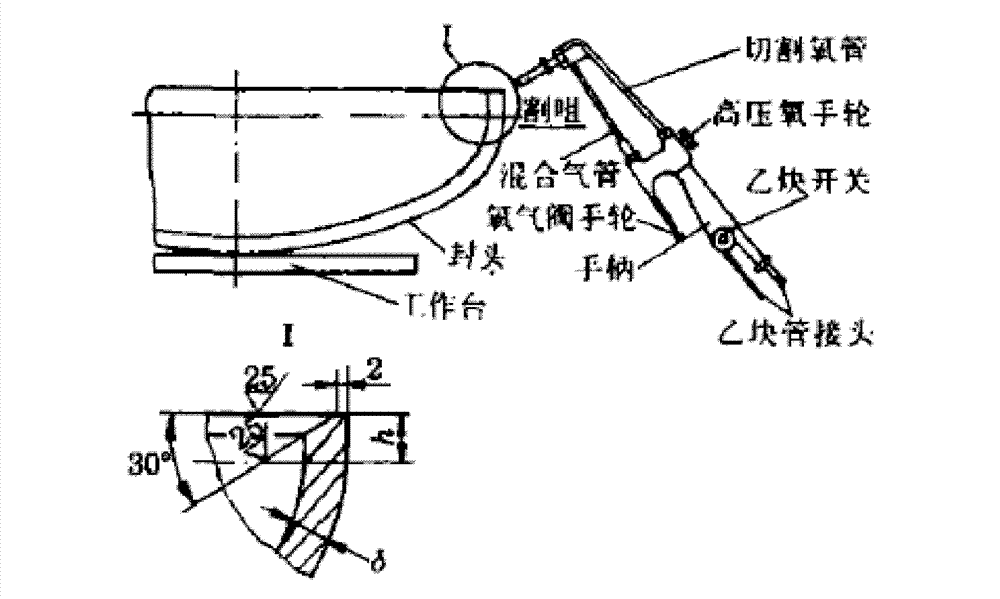

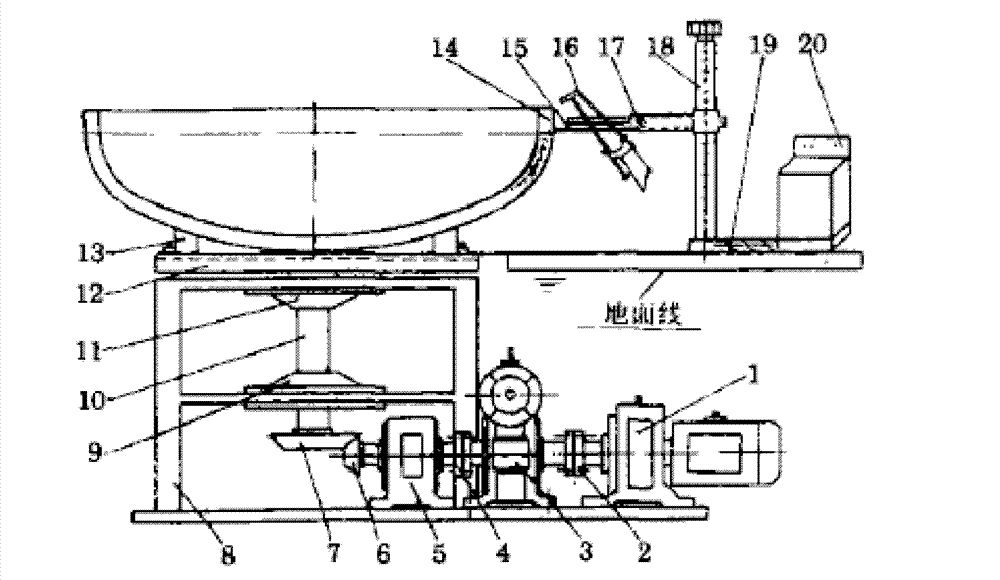

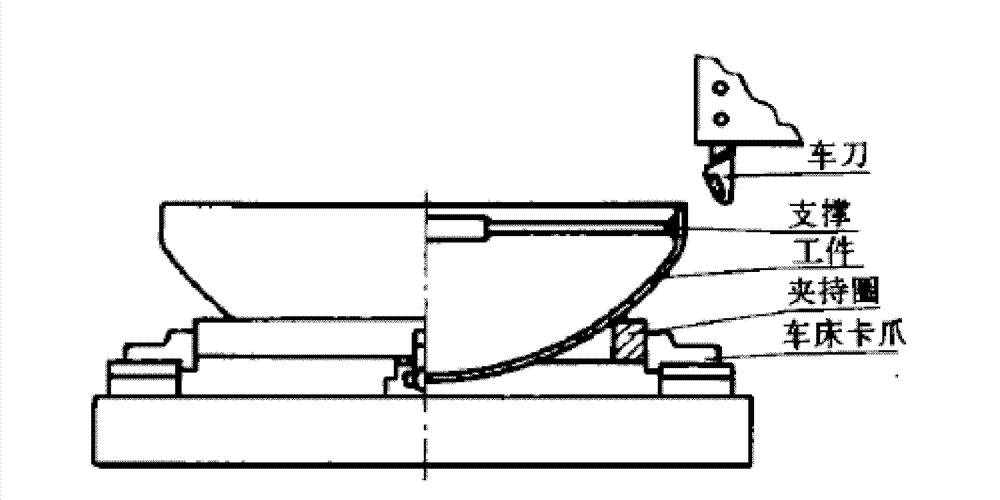

[0037] see Figure 4-6 , The head bevel edge grinding machine of the present invention mainly includes several major parts such as a frame, an angle adjustment part, a lifting adjustment part, a lateral movement part and an angle grinder. The head F to be processed rotates on the disk, and the disk adopts the prior art, such as figure 2 The disc shown is no longer described in detail. The frame has two fixed pressing wheels that are always in contact with the end face and the outer wall of the head, and it also has a movable pressing wheel, which is pressed against the inner wall of the head under the action of a cylinder, so as to ensure The relative position of the frame and the head remains unchanged. The angle grinder E is installed on the lateral moving part, and the lateral moving part can adjust the position of the angle grinder in the cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com