Plant juice extractor for cosmetic production

A technology for plant liquids and cosmetics, applied in presses, manufacturing tools, etc., can solve problems such as low extraction rate, and achieve the effects of improving extraction rate, thorough extrusion, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

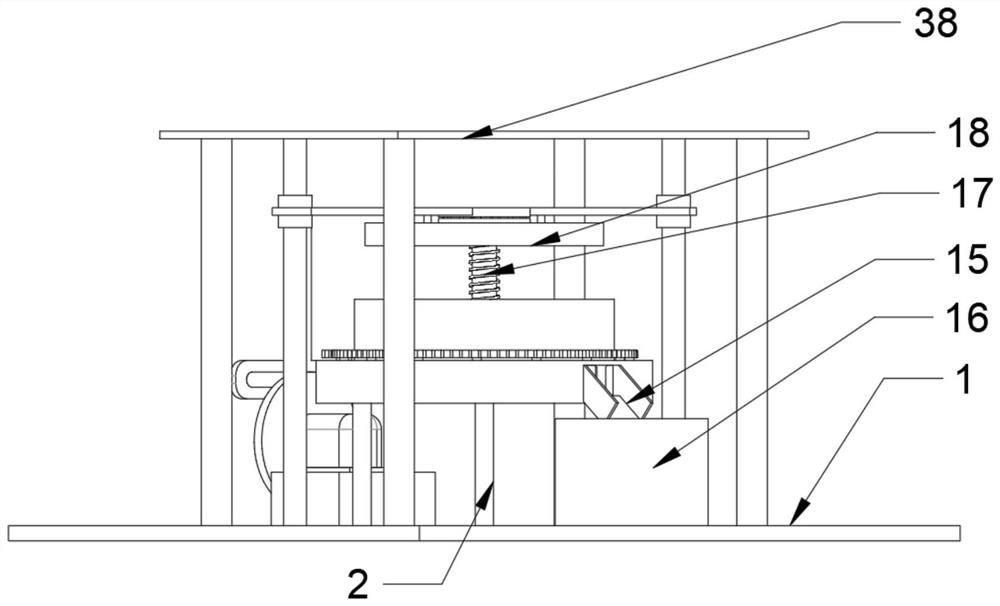

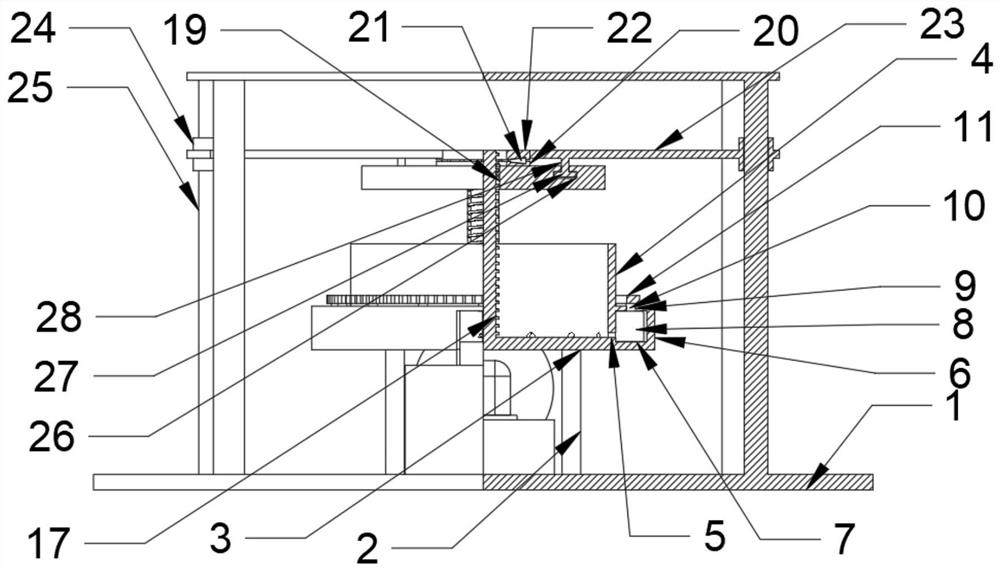

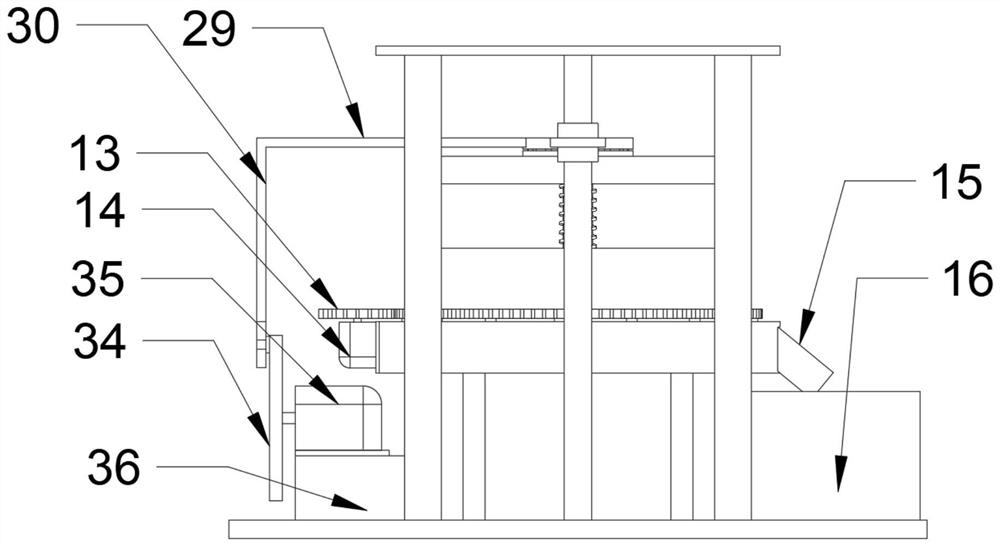

[0025] refer to Figure 1~5 , in an embodiment of the present invention, a plant juice extractor for cosmetic production, comprising a base 1, the base 1, a first support rod 2 fixedly connected to the middle position of the base 1, and a top end of the first support rod 2 fixedly connected to The upper fixed plate 3 is fixedly connected with the raw material cylinder 4 at the middle position of the upper surface of the upper fixed plate 3, and the bottom end of the inner wall of the raw material cylinder 4 is provided with a liquid outlet 5, and the edge of the upper surface of the upper fixed plate 3 is fixedly connected with an outer plate 6, and the outer A material guide groove 7 is formed between the plate 6 and the outer wall of the raw material cylinder 4, and the plant material in the raw material cylinder 4 is squeezed by the briquette 18, and the plant juice starts to be discharged, and the extruded plant juice flows into the guide through the liquid outlet 5. In th...

Embodiment 2

[0028] refer to figure 1 The present invention also provides another embodiment. The difference between this embodiment and the above embodiment is that a second support rod 37 is fixedly connected to the corner of the base 1, and a top end of the second support rod 37 is fixedly connected to a The upper baffle 38, the device is shielded by the setting of the upper baffle 38, reducing dust and other sundries from falling into the device and affecting the quality of the product.

[0029]The working principle of the present invention is: the device drives the flywheel 34 to rotate through the second motor 35. The flywheel 34 drives the block 33 to rotate, and the block 33 drives the fixed rod 31 to lift through the second slide rail 32, and the fixed rod 31 passes through the lifting rod 30. Drive the rear connecting rod 29 to lift, and the rear connecting rod 29 drives the upper bearing plate 22 to lift. When the upper bearing plate 22 is lowered under the drive of the rear con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com