Device for rotating and pressing dumplings

A technology of rotary pressing and dumplings, applied in baking, dough processing, food science and other directions, can solve the problems of reduced service life of the wrapping mechanism, poor appearance quality of dumplings, increased friction between the slider and the slide rail, etc. The effect of improving the service life, improving the appearance and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

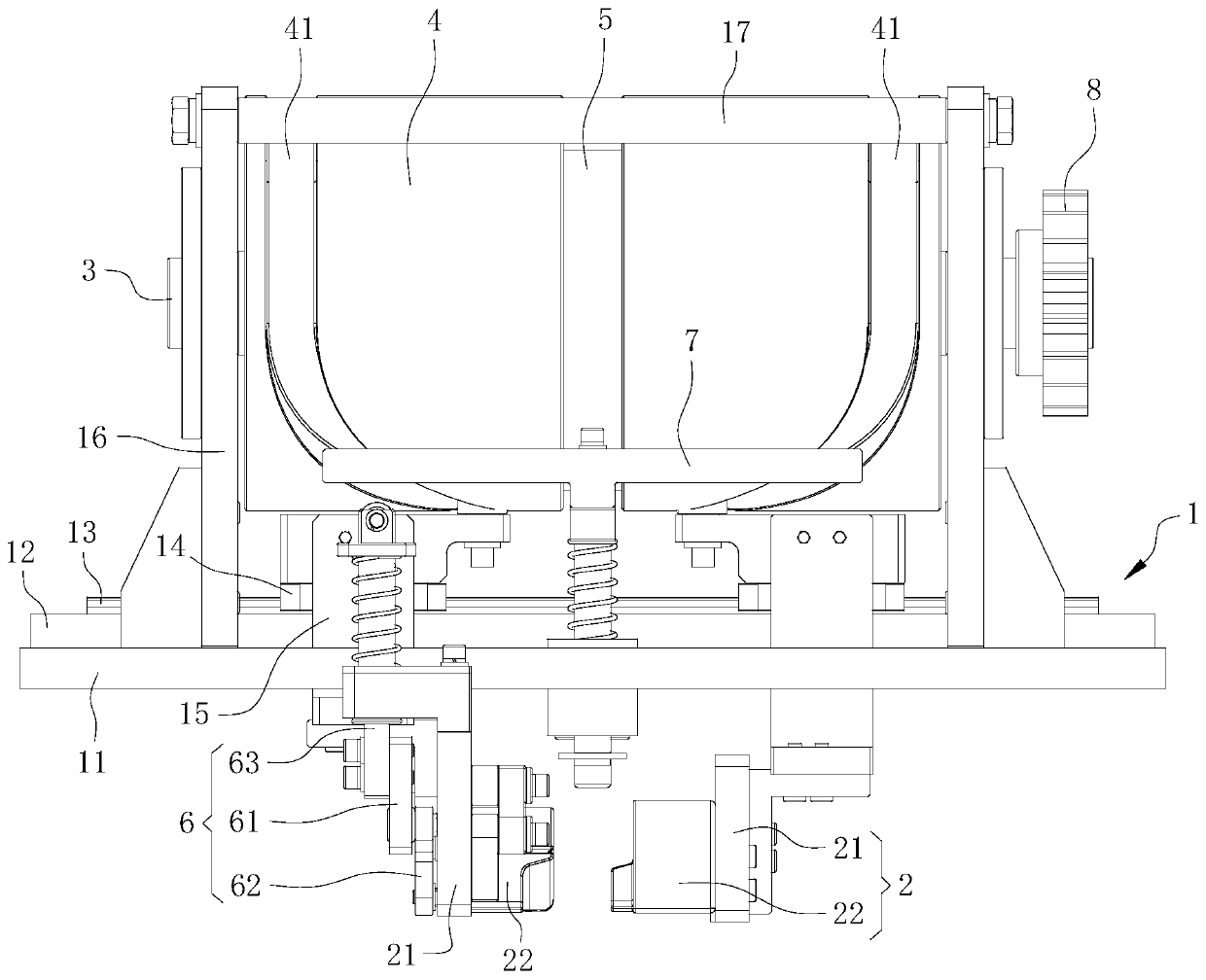

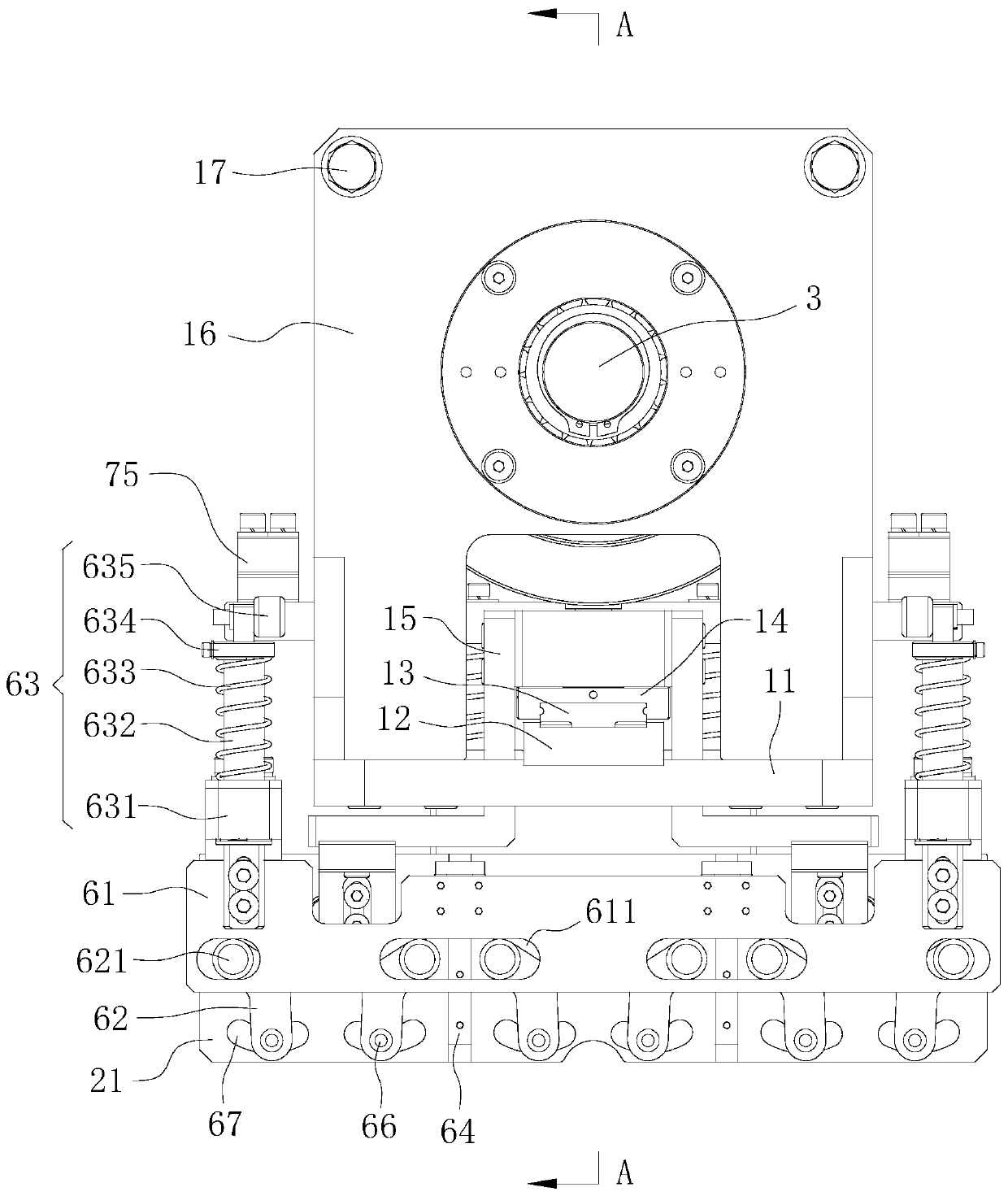

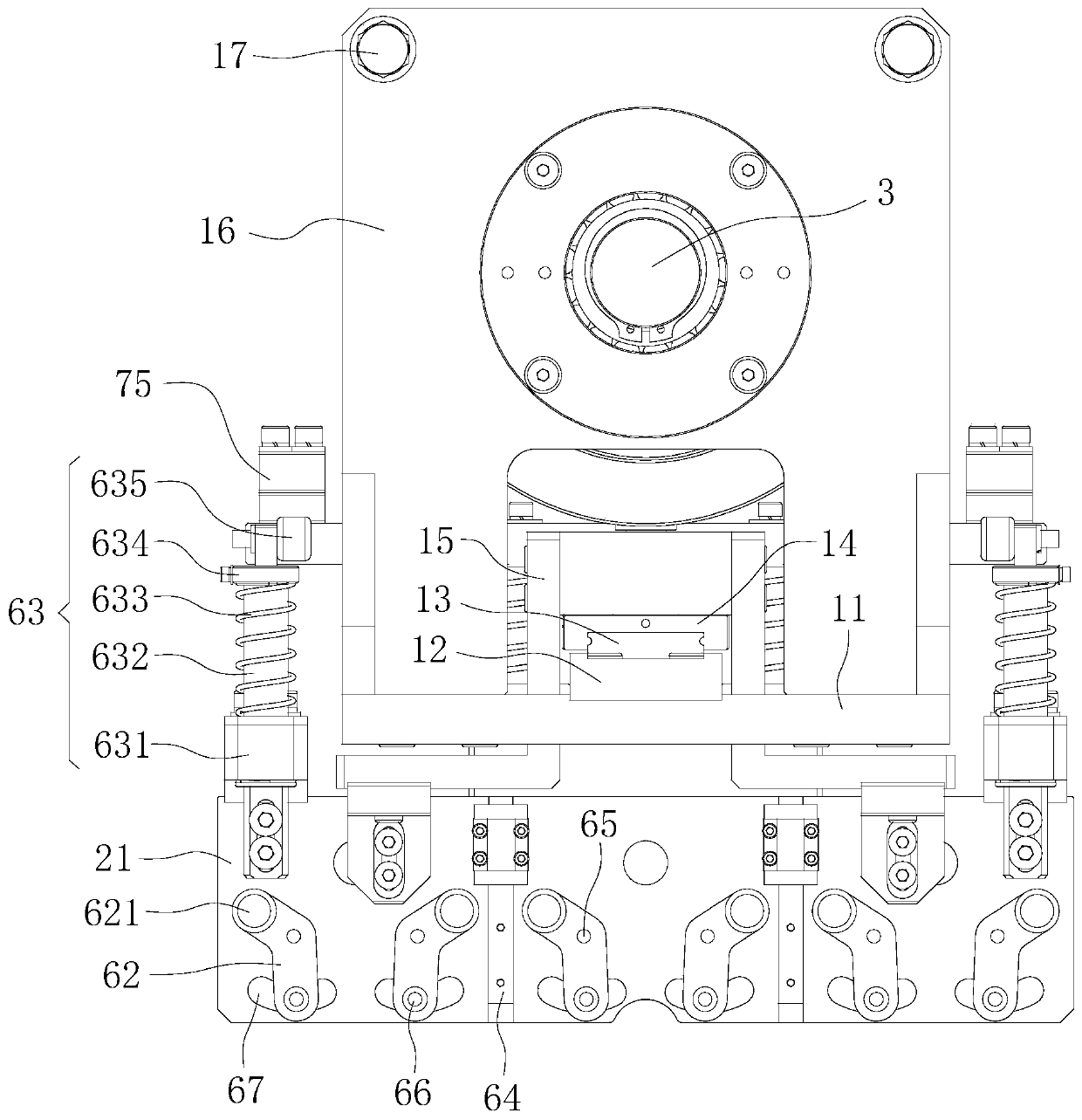

[0030]The dumpling rotary press-fitting device of the present invention comprises a mounting frame 1 and two opposite mold clamping parts 2 ; The combined module 22 on the first mounting plate 21; the combined module 22 on at least one first mounting plate 21 includes two extruded mold halves 221 that are rotatably arranged on the first mounting plate 21; A horizontal rotating shaft 3 is provided; a space cam 4 and a disk cam 5 are sleeved on the horizontal rotating shaft 3; grooves 41 corresponding to each clamping part 2 are arranged on the outer peripheral surface of the space cam 4, and the grooves The groove 41 is fitted with the first roller 42 arranged on the clamping mold part 2; the first mounting plate 21 is also provided with a rotary drive assembly 6 that drives the two extruding mold halves 221 to squeeze each other. The mounting frame 1 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com