Glass cup packaging equipment for product wholesale

A technology of packaging equipment and glasses, which is applied in the field of glass packaging equipment for wholesale products, can solve the problems of high cost, low efficiency, unsafe manual packaging, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

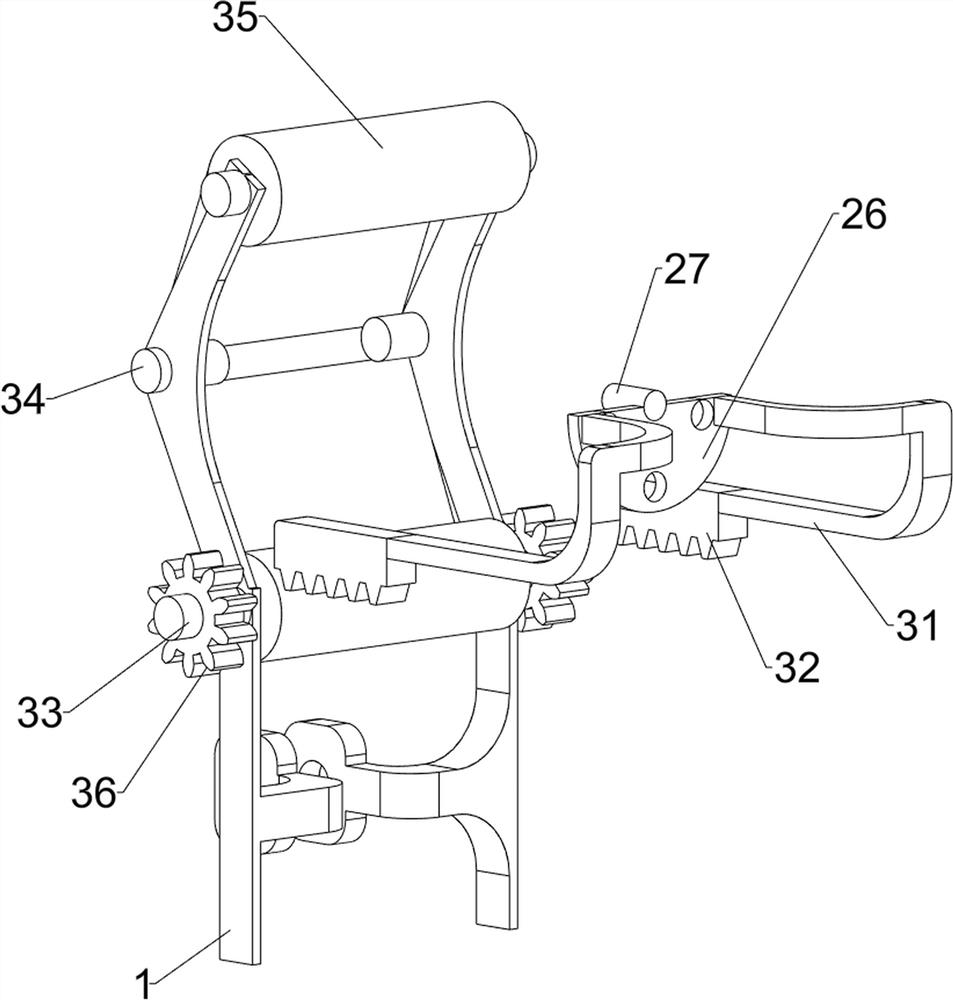

[0080] A kind of glass packaging equipment for wholesale products, such as figure 1 and figure 2 As shown, it includes a bottom plate 1, a push mechanism 2 and a film sealing mechanism 3. The bottom plate 1 is provided with a push mechanism 2 at the upper rear, and the bottom plate 1 is provided with a film sealing mechanism 3 at the upper middle. The push mechanism 2 is connected with the film sealing mechanism 3.

[0081] Manual packaging is unsafe, low in efficiency and high in cost. This equipment can automatically pack glasses, which is safe, efficient and can reduce costs. First, people put glasses in the push mechanism 2, and then make the push mechanism 2 run , the push mechanism 2 moves the glass forward. When the glass passes through the sealing film mechanism 3, the sealing film mechanism 3 seals it and packs it. When the packaged glass is removed from the sealing film mechanism 3, people make the glass Come off, then take away the packaged glass, when the pushing...

Embodiment 2

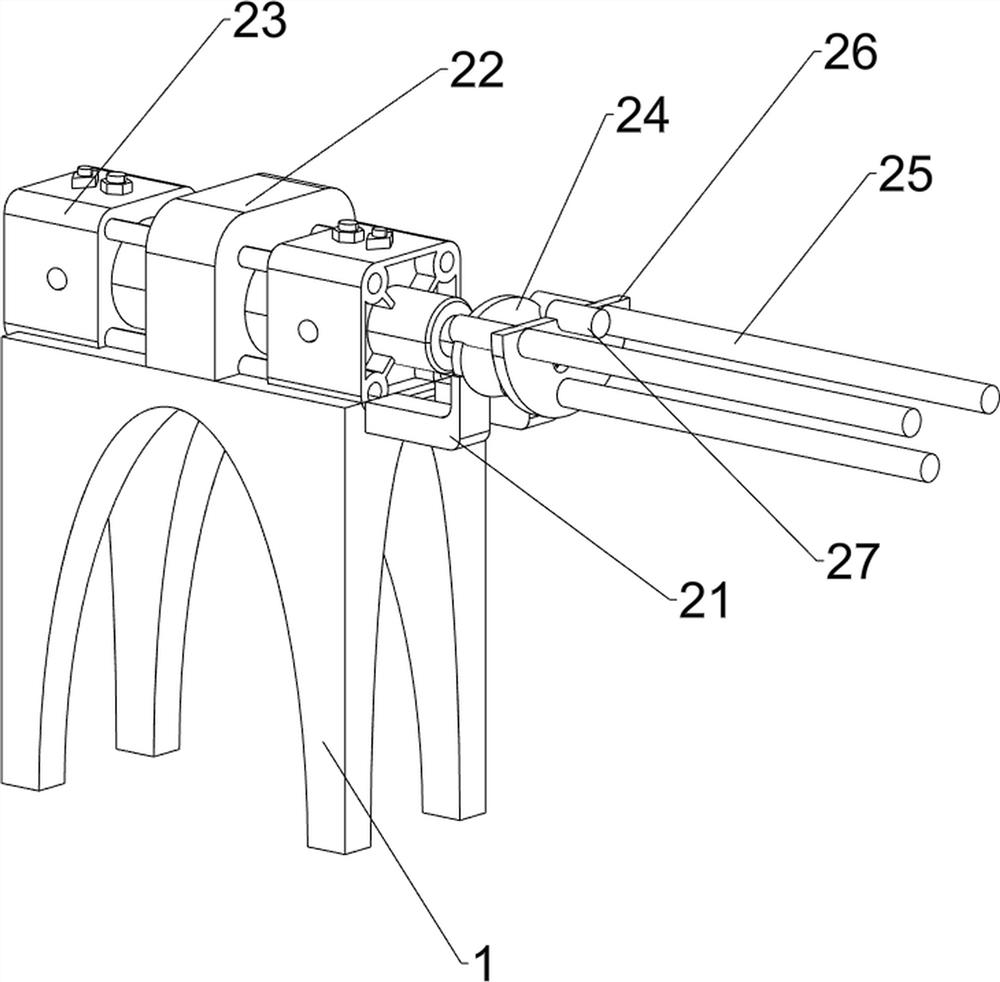

[0083] On the basis of Example 1, such as image 3 and Figure 4 As shown, the pushing mechanism 2 includes a first fixed block 21, a second fixed block 22, a cylinder 23, a fixed plate 24, a bracket 25, a push plate 26 and a top block 27, and the bottom plate 1 is provided with a second fixed block 22 at the rear. The inner side of the second fixed block 22 is provided with a cylinder 23, the upper rear portion of the base plate 1 is provided with two first fixed blocks 21, and a fixed plate 24 is connected between the tops of the two first fixed blocks 21, the fixed plate 24 and the cylinder 23 The output shaft is slidingly connected, and the front side of the output shaft of the cylinder 23 is provided with a push plate 26. There are three supports 25 connected between the push plate 26 and the fixed plate 24. The support 25 is connected with the push plate 26 in a sliding manner. Top block 27 is provided.

[0084] People put the glass in the support 25, then open the cyl...

Embodiment 3

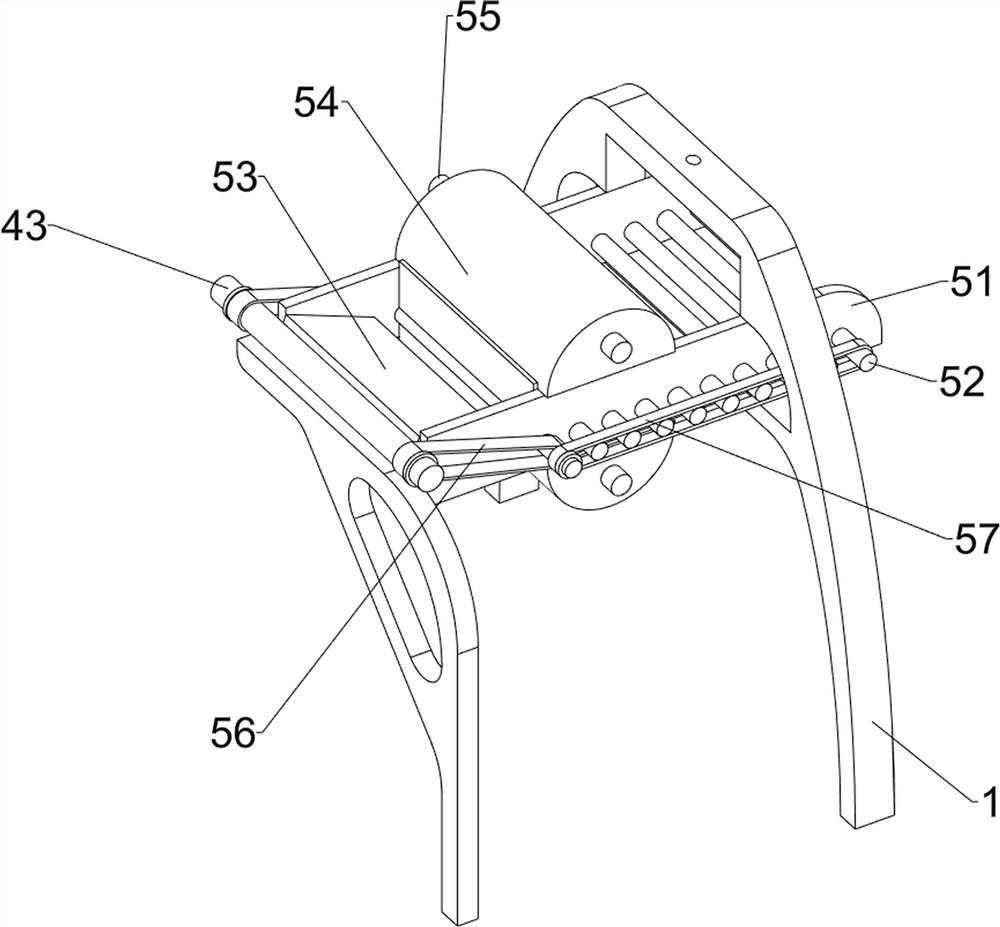

[0088] On the basis of Example 2, such as figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a hot pressing mechanism 4 is also included, and the hot pressing mechanism 4 includes a servo motor 41, a first material blocking plate 42, a second rotating shaft 43, a transmission assembly 44, a first elastic assembly 45, a moving pressing plate 46, a second elastic Component 47, hot-melt cutter 48, second connecting block 49, second rack 410, third rotating shaft 411, second one-way gear 412, rope reel 413, rope guide block 414 and pull rope 415, on the left side of bottom plate 1 The middle part is equipped with a servo motor 41, and the bottom plate 1 is provided with two first material retaining plates 42, and two second rotating shafts 43 are rotationally connected between the first material retaining plates 42 on the left and right sides, and the second rotating shaft on the rear side 43 is connected to the output shaft of the servo motor 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com