Semi-automatic rapid hand-changing lifting device

A lifting device and semi-automatic technology, applied in the direction of lifting device, etc., can solve the problems of high labor intensity, consuming a lot of manpower and material resources, low operation efficiency, etc., so as to reduce labor intensity, reduce the amount of auxiliary measures, improve safety, reliability and operation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

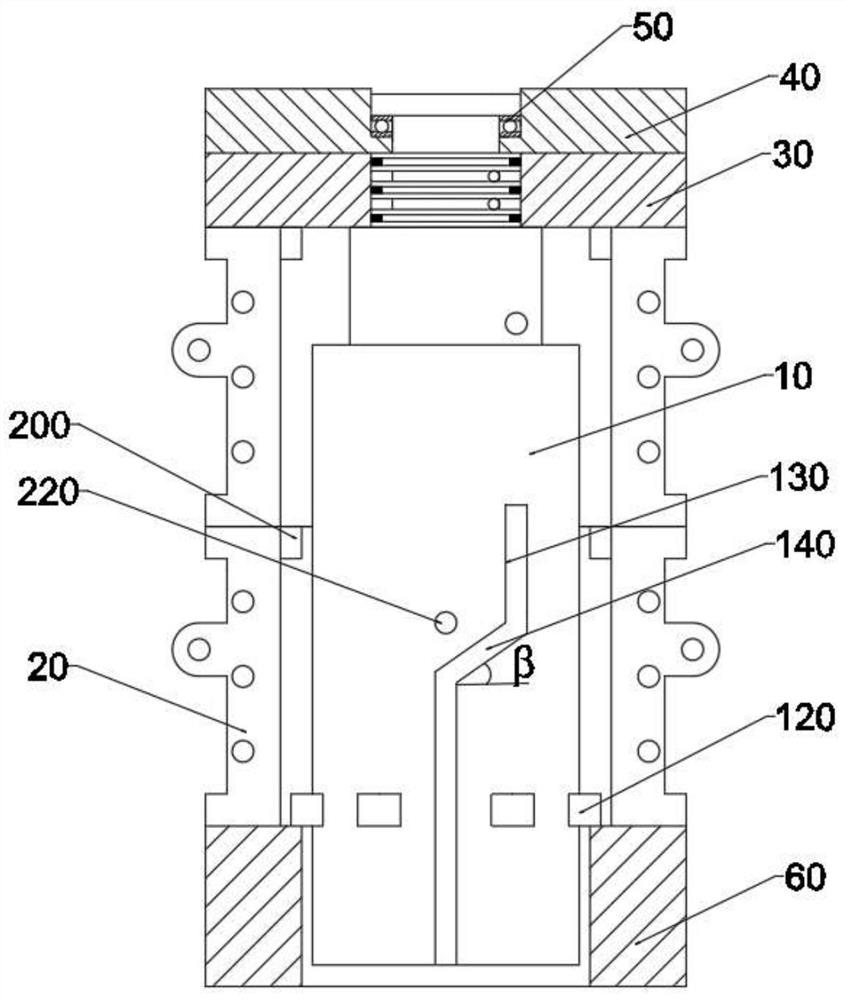

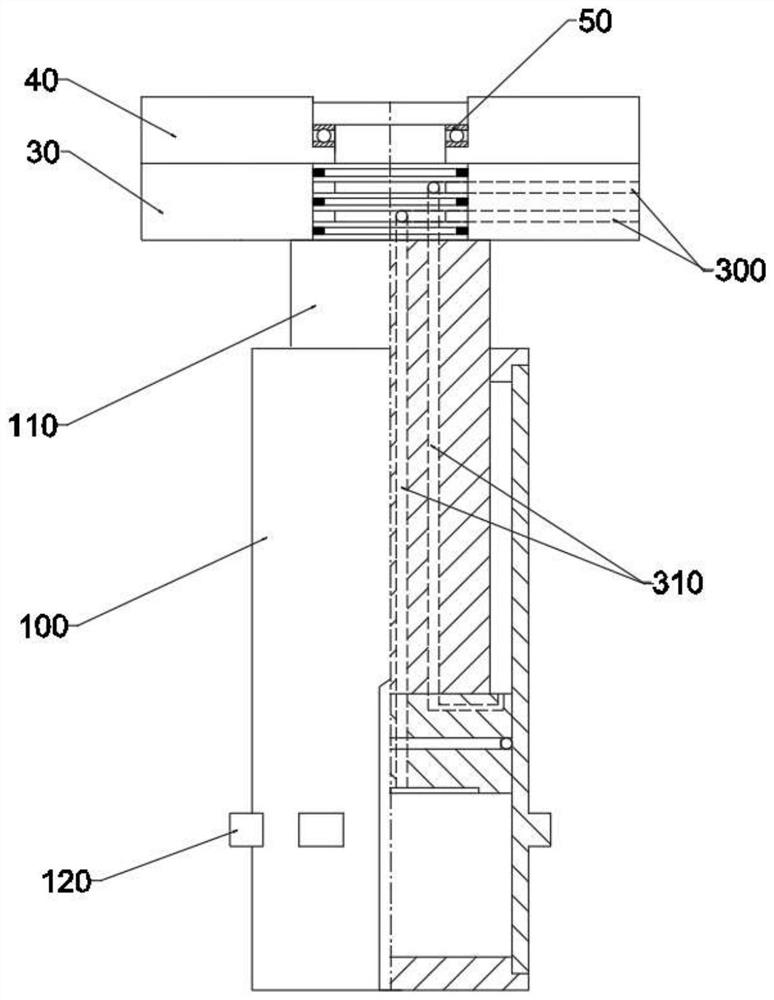

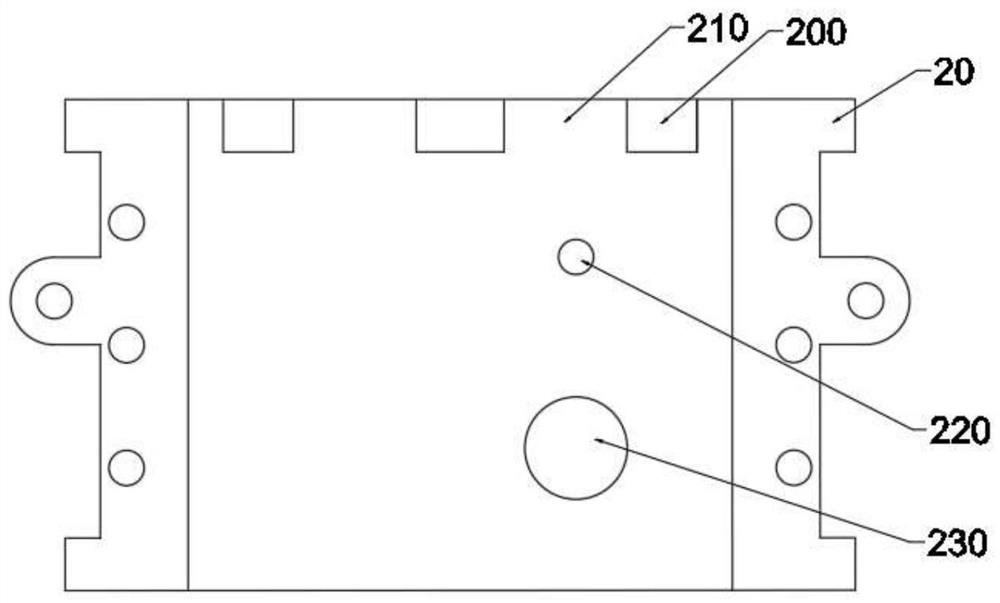

[0032] In order to make the purpose, advantages and features of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the drawings are all in very simplified form and not drawn to scale, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention. In addition, the structures shown in the drawings are often a part of the actual structures. In particular, each drawing needs to display different emphases, and sometimes uses different scales. It should also be understood that, unless otherwise specified or pointed out, the terms “first”, “second”, “third” and other descriptions in the specification are only used to distinguish each component, element, step, etc. in the specification, rather than It is used to express the logical relationship or sequence relationship between various comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com