Large smelting blast furnace shell position adjusting device

A blast furnace shell and adjustment device technology, applied in the blast furnace, blast furnace details, blast furnace parts, etc., can solve problems affecting safe production, damage to the furnace shell, damage to the furnace shell, etc., to ensure safe production, reduce input costs, The effect of continuous completion of deviation correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

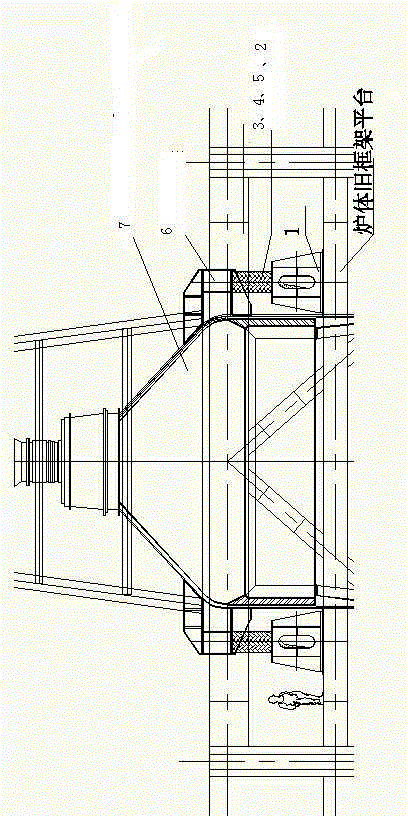

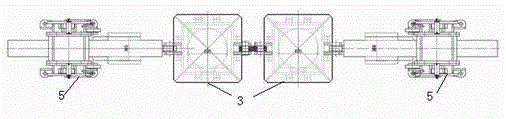

[0015] Such as figure 1 and figure 2 As shown, the present invention is a large-scale smelting blast furnace shell position adjustment device, which comprises: the furnace shell well-shaped support beam 1 is placed on the frame below the ring beam 6 of the furnace shell 7, and the well-shaped support beam is provided with a reducing Loading and anti-falling device 2, hydraulic jacking device 3, deviation correcting device 4 and sliding device 5; the furnace shell is located in the center of the well-shaped support beam 1, and the load-reducing and anti-falling device 2 includes a set of The spring support components are fixed on the well-shaped support beams and support the ring beams.

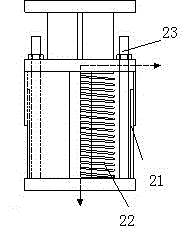

[0016] From image 3 It can be seen that in the position adjustment device for the large-scale smelting blast furnace shell, the spring support assembly includes a sleeve 21 that fits up and down. The upper and lower sleeves are provided with support rods, and the upper sleeve can m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com