A continuous process for the preparation of oil-based feedstock for mesophase pitch and pitch-based carbon fiber production

A technology of pitch-based carbon fiber and mesophase pitch, which is applied in the processing of tar pitch/petroleum pitch/natural pitch, tar pitch/petroleum pitch/natural pitch by distillation, tar pitch/petroleum pitch/natural pitch by selective extraction, etc. It can solve the problems of high softening point, poor spinnability of mesophase pitch, lack of hydrofining unit, etc., and achieve the effect of improving production efficiency and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

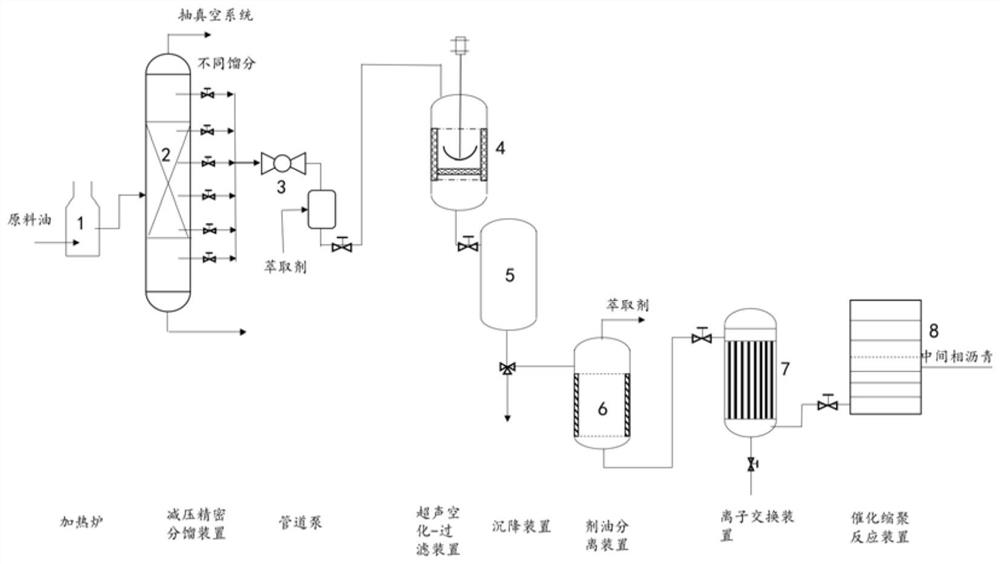

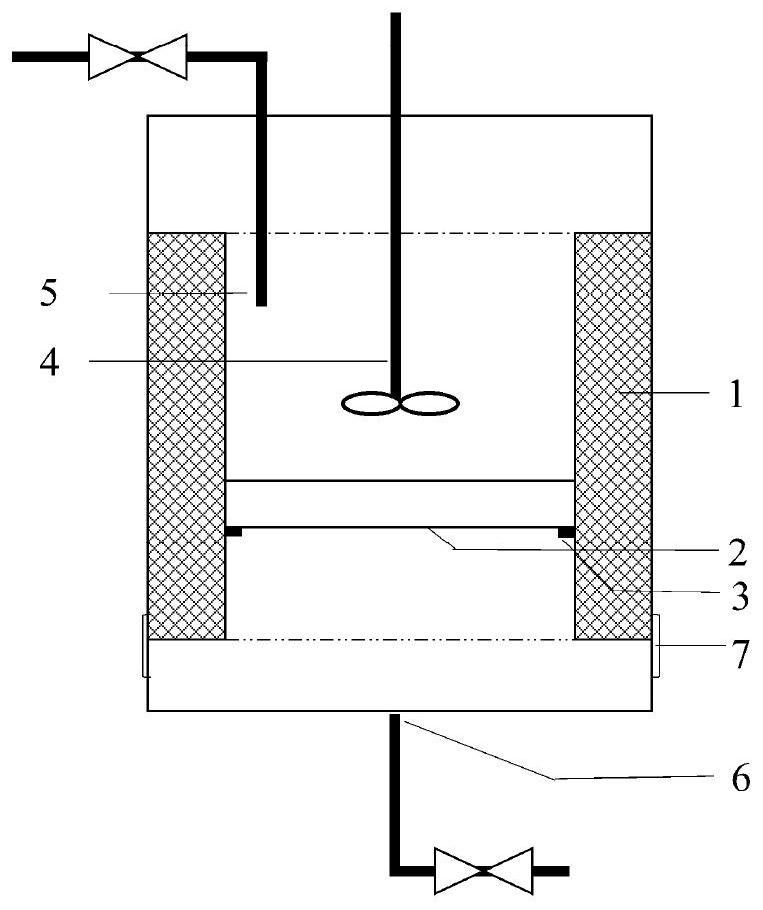

Embodiment 1

[0032] Add 3.5kg of ethylene tar into the vacuum precision fractionation unit, the temperature of entering the tower is 200°C, the absolute pressure is 5KPa, and the fraction oil above 300°C is separated by vacuum precision deep drawing, and the corresponding valve is opened to introduce the fraction oil and the extractant at the same time Ultrasonic-assisted filtration deashing coupling enhanced extraction unit, in which dimethylformamide (DMF) is selected as the extraction agent, the agent-oil ratio is 5:1, the power of the ultrasonic generator is adjusted to 700W, the temperature of the mixed material is 90°C, and the aperture The ceramic membrane of 20nm is used as filter medium, then the filtrate is subjected to static sedimentation and agent oil separation, then the raw material oil after the treatment is introduced into the ion exchange device, and passed through n-heptane, toluene, toluene-ethanol=1:1 (volume ratio) solvent, the temperature of the ion exchange unit is m...

Embodiment 2

[0035] Add 3.5kg of ethylene tar into the vacuum precision fractionation unit, the temperature of entering the tower is 200°C, the absolute pressure is 5KPa, and the fraction oil above 300°C is separated by vacuum precision deep drawing, and the corresponding valve is opened to introduce the fraction oil and the extractant at the same time Ultrasonic-assisted filtration deashing coupling enhanced extraction unit, in which N-methylpyrrolidone (NMP) is selected as the extraction agent, the agent-oil ratio is 5:1, the power of the ultrasonic generator is adjusted to 900W, the temperature of the mixed material is 90°C, and the aperture The ceramic membrane of 20nm is used as filter medium, then the filtrate is subjected to static sedimentation and agent oil separation, then the raw material oil after the treatment is introduced into the ion exchange device, and passed through n-heptane, toluene, toluene-ethanol=1:1 (volume ratio) solvent, the temperature of the ion exchange unit is...

Embodiment 3

[0038] Add 3.5kg of ethylene tar into the vacuum precision fractionation unit, the temperature of entering the tower is 200°C, the absolute pressure is 5KPa, and the fraction oil above 300°C is separated by vacuum precision deep drawing, and the corresponding valve is opened to introduce the fraction oil and the extractant at the same time Ultrasonic-assisted filtration deashing coupling enhanced extraction unit, in which furfural is selected as the extraction agent, the agent-oil ratio is 4:1, the power of the ultrasonic generator is adjusted to 800W, the temperature of the mixed material is 80°C, and a ceramic membrane with a pore size of 50nm is used as the filter Medium, then the filtrate is subjected to static sedimentation and agent oil separation, and then the treated raw oil is introduced into the ion exchange device, and passed into n-heptane, toluene, toluene-ethanol=1:1 (volume ratio) solvent, ion exchange unit The temperature is maintained at 100°C, and compounds co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com