Shape memory alloy energy dissipation shock absorber

A memory alloy and shock absorber technology, which is applied in the field of shape memory alloy energy dissipation shock absorbers, can solve problems such as inability to fully exert hysteretic performance, insufficient hysteretic energy dissipation capacity of nodes, and small initial stiffness of nodes, etc., to improve the structure Energy dissipation capacity, unique and reasonable device structure, and the effect of improving the stiffness of nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

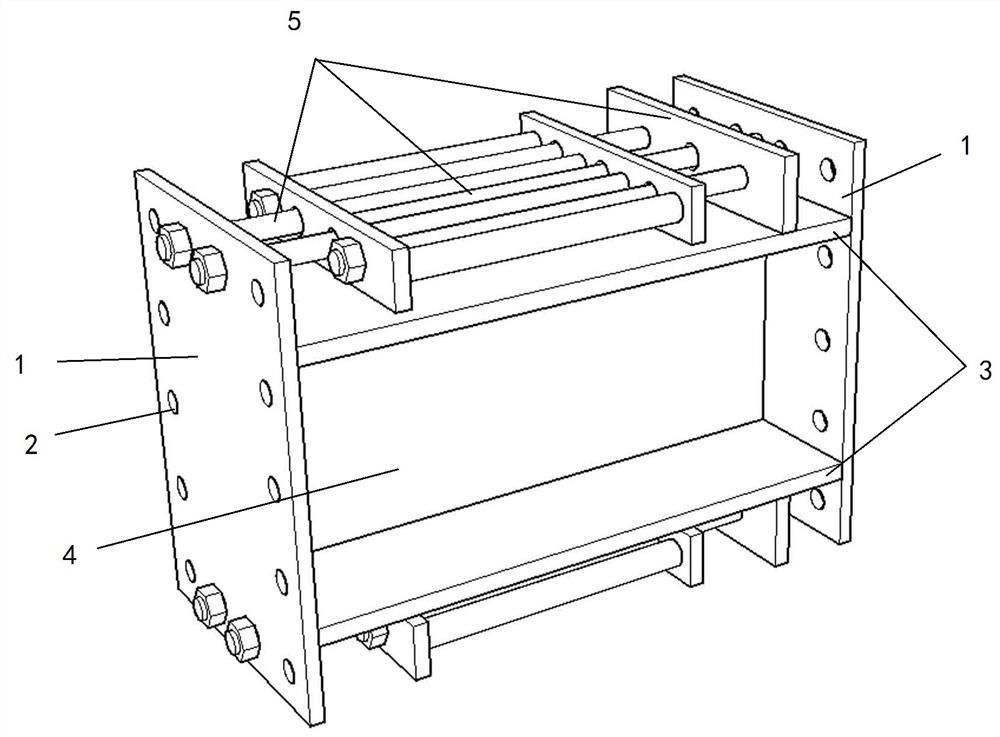

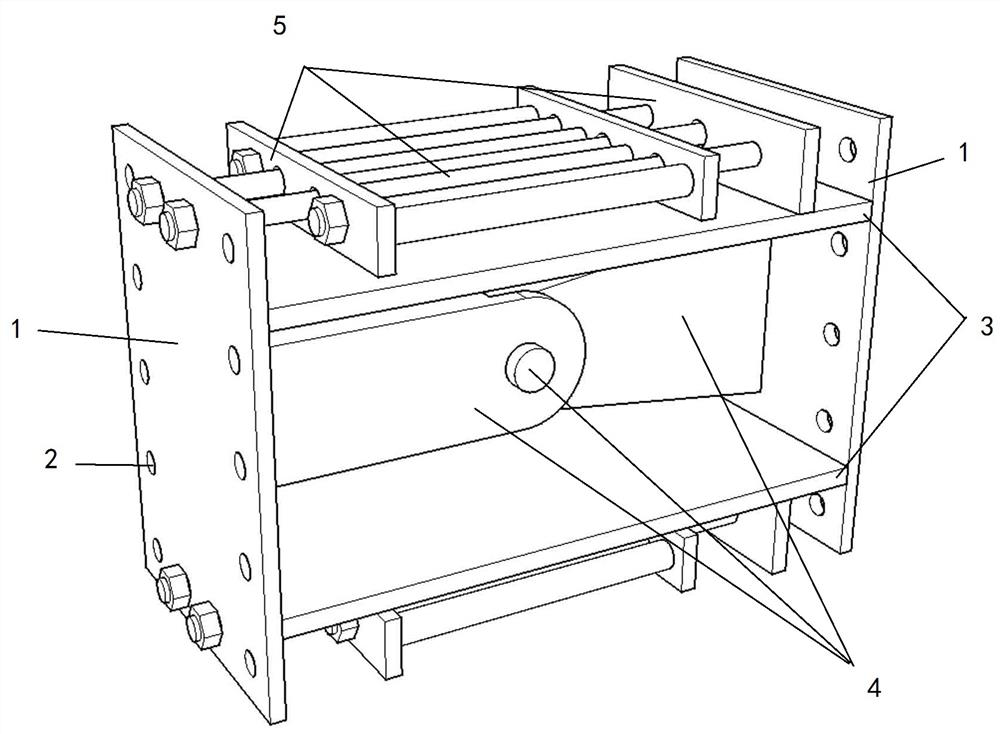

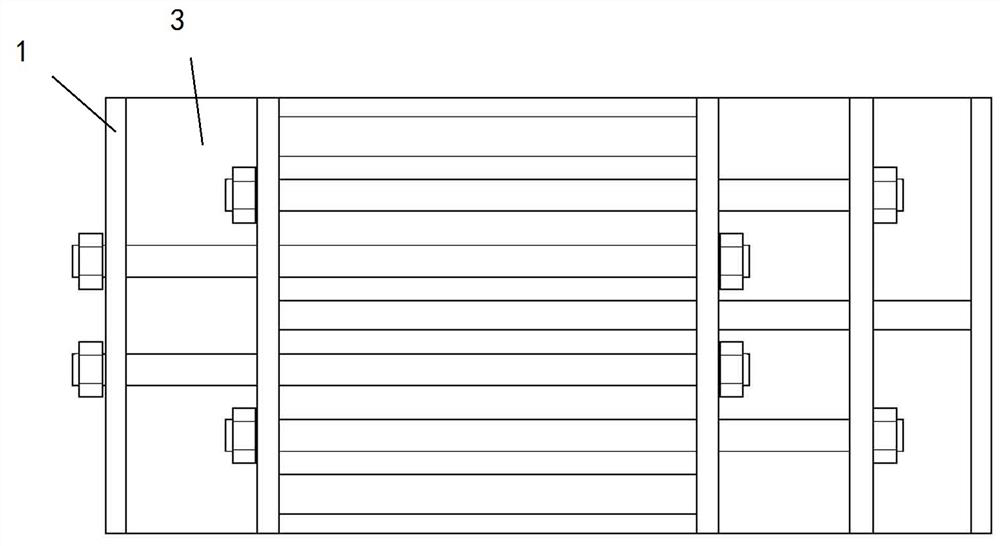

[0028] like Figure 1-8 Among them, the shape memory alloy energy-dissipating shock absorber includes symmetrically arranged mounting plates 1, and multiple sets of first mounting holes 2 are arranged on the described mounting plates 1, and symmetrically arranged first mounting holes 2 are arranged between the symmetrically arranged mounting plates 1. A connecting plate 3, a connecting structure 4 and a symmetrically arranged damping structure 5, the connecting structure 4 is located between the symmetrically arranged first connecting plates 3;

[0029] The damping structure 5 includes a second connecting plate 10 connected to the first connecting plate 3, and the second connecting plate 10 is provided with a mounting hole 11. There is a first matching plate 12 and a second matching plate 12' between them, the first matching plate 12 and the second matching plate 12' are connected by a plurality of connecting rods 13, and the first matching plate 12 is provided with a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com