Mounting method of large-diameter hollow rivet for bamboo structure

An installation method and large-diameter technology, applied in the directions of rivets, pins, connecting components, etc., can solve the problems of low stiffness, large initial pores, poor ductility, etc., and achieve the effect of improving the stiffness of joints, facilitating production and processing, and designing flexible designs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

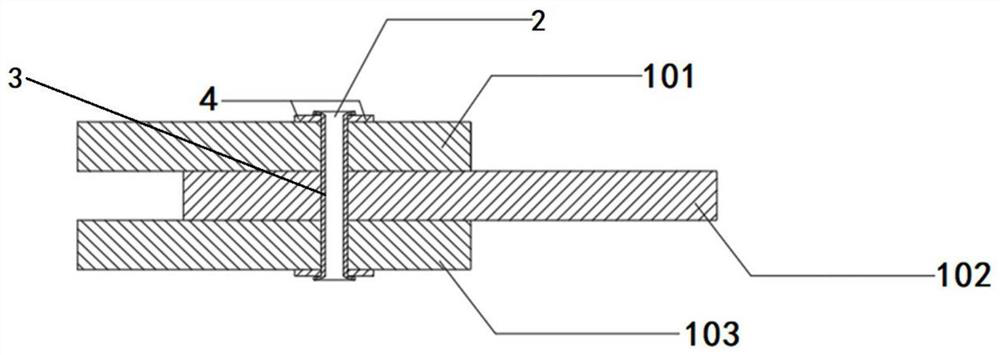

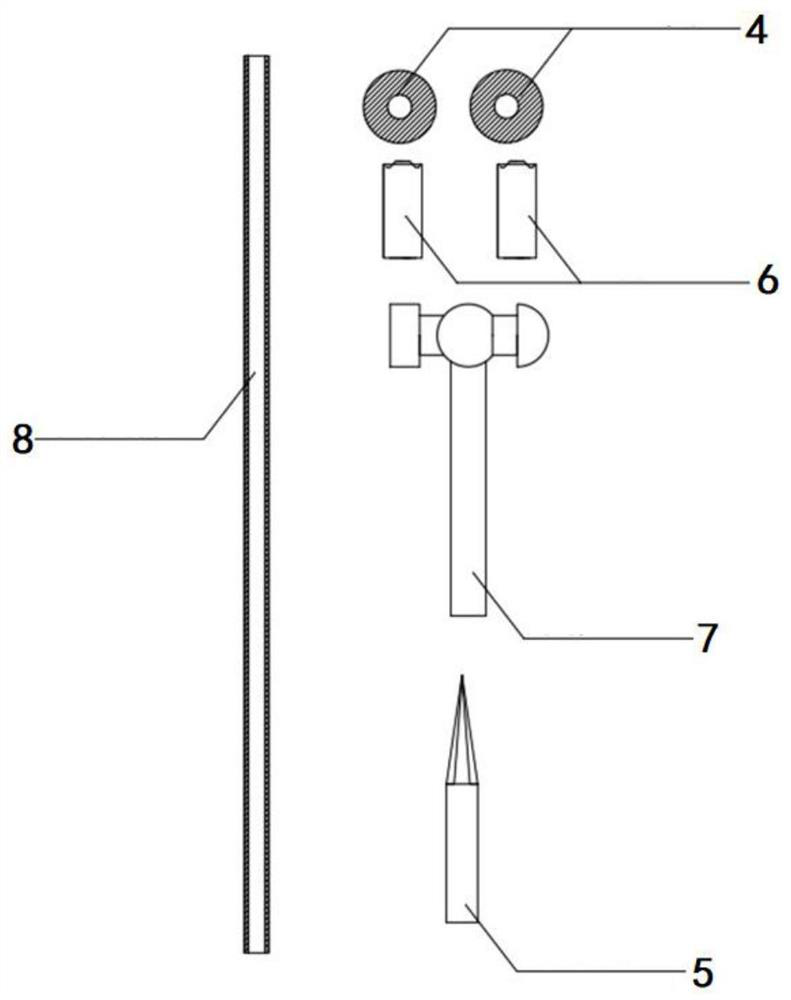

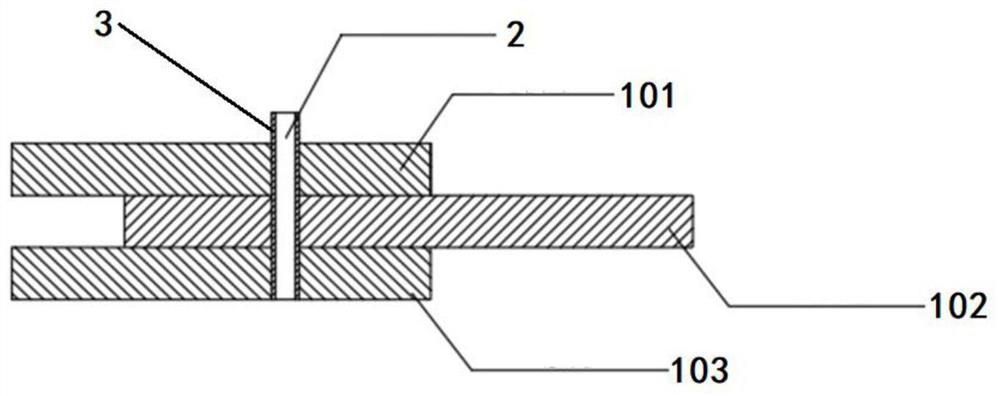

[0032] see Figure 1-Figure 7 , the present embodiment 1 provides a method for installing a large-diameter hollow rivet for bamboo and wood structures, which is characterized in that it includes:

[0033] Step S1: Drill holes on the multi-layer connection plate to be riveted to form a through hole 2, insert the matching hollow rivet 3 into the through hole 2, and ensure that both ends of the hollow rivet 3 pass through the multi-layer connection plate at a certain distance.

[0034] Specifically, the multi-layer connecting board used in this embodiment is a three-layer bamboo-wood connecting board structure, including: an upper connecting board 101, a middle connecting board 102, and a lower connecting board 103; the hollow core used in this embodiment The rivet 3 is made by cutting the steel pipe 8 into a suitable length by cutting equipment, and it is necessary to ensure that no cracks are generated during the cutting process, and then it is necessary to use sandpaper to po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com