A kind of prefabricated steel strip concrete composite shear wall and its production and construction method

A technology of concrete shear walls and combined shear walls, which is applied to walls, buildings, building components, etc., can solve the problems of reinforced concrete shear walls such as good ductility, poor ductility and energy dissipation capacity, cumbersome operation, etc., and achieve bending resistance and good shear resistance, increased ductility and energy dissipation capacity, and clear force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with embodiment and description of drawings.

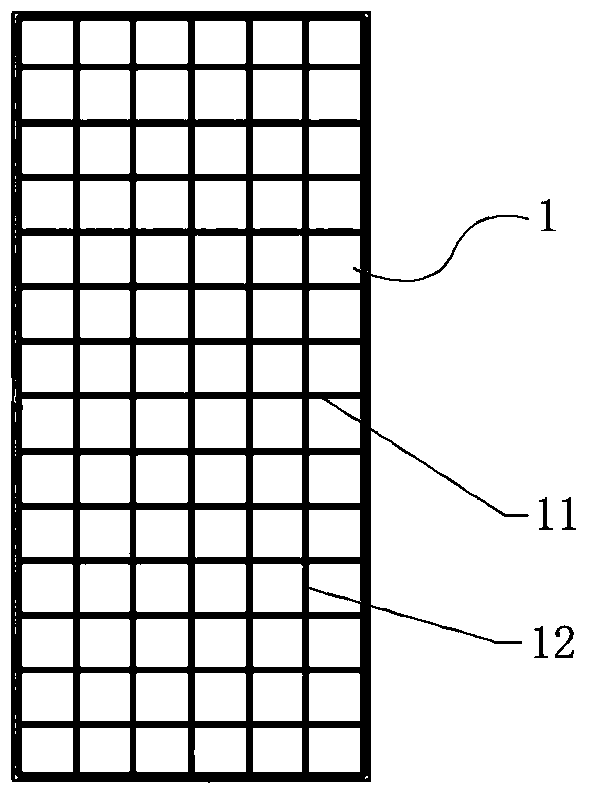

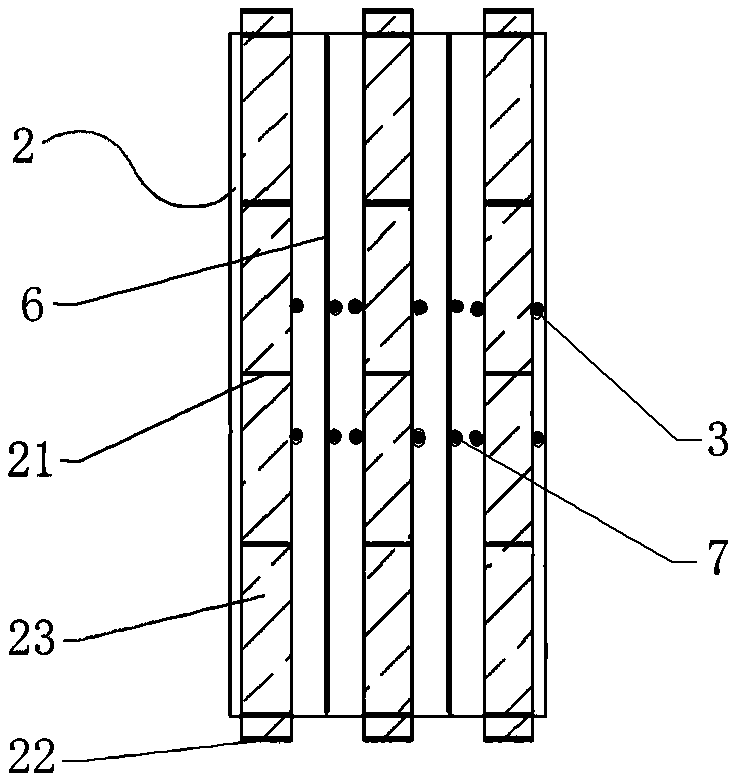

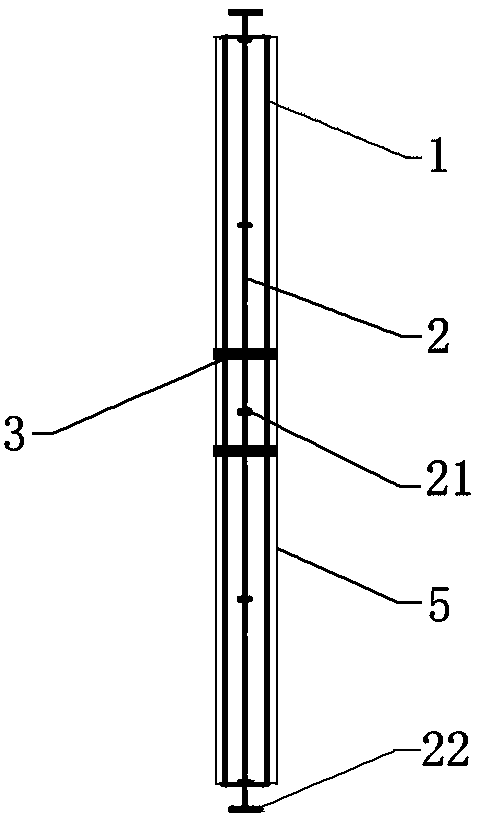

[0033] An assembled steel plate strip concrete composite shear wall of the present invention includes a concrete shear wall 5 and an inner skeleton embedded in the concrete shear wall 5, the inner skeleton has three layers, including the front and rear surface layers embedded in the concrete shear wall 5 The two distributed reinforcement meshes 1 in the interior, and the steel plate strips 2 arranged in the middle layer of the concrete shear wall 5; Composed of steel bars 11 and vertical steel bars 12, the maximum distance between adjacent horizontal steel bars 11 or vertical steel bars 12 is 200mm, and the minimum reinforcement ratio of distributed steel mesh 1 is 0.4%; steel plate strip 2 includes steel plate 23, flange plate 22. The middle vertical steel bars 6 and stiffeners 21, the steel slats 23 are arranged vertically, and are distributed on the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com