Ash bucket plastering plate connecting device for automatic plastering machine

A plastering machine and board connection technology, applied in the direction of construction, building structure, etc., can solve the problems of labor-intensive material loading, increase construction cost, increase the burden of construction workers, etc., to reduce work intensity, save construction cost, The effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

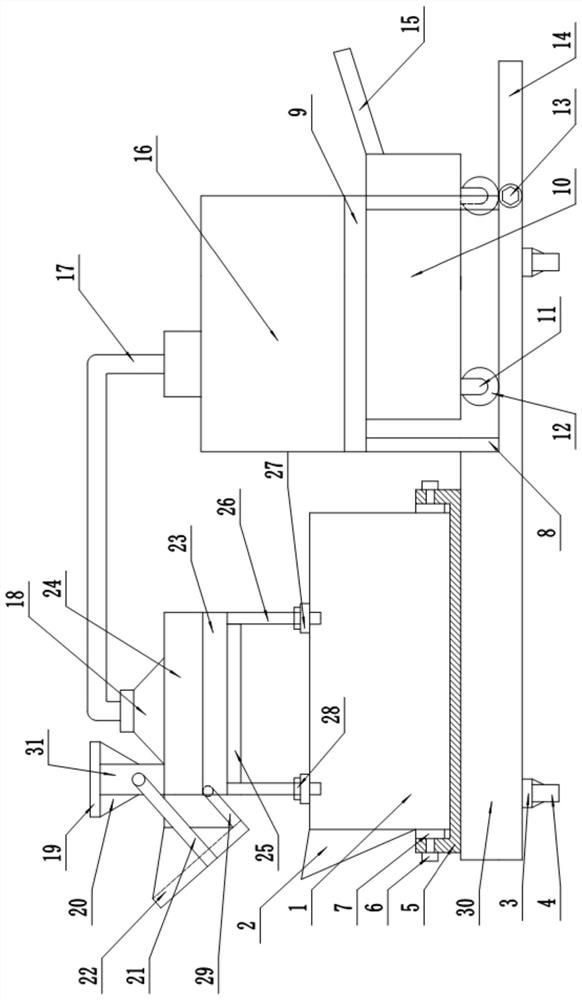

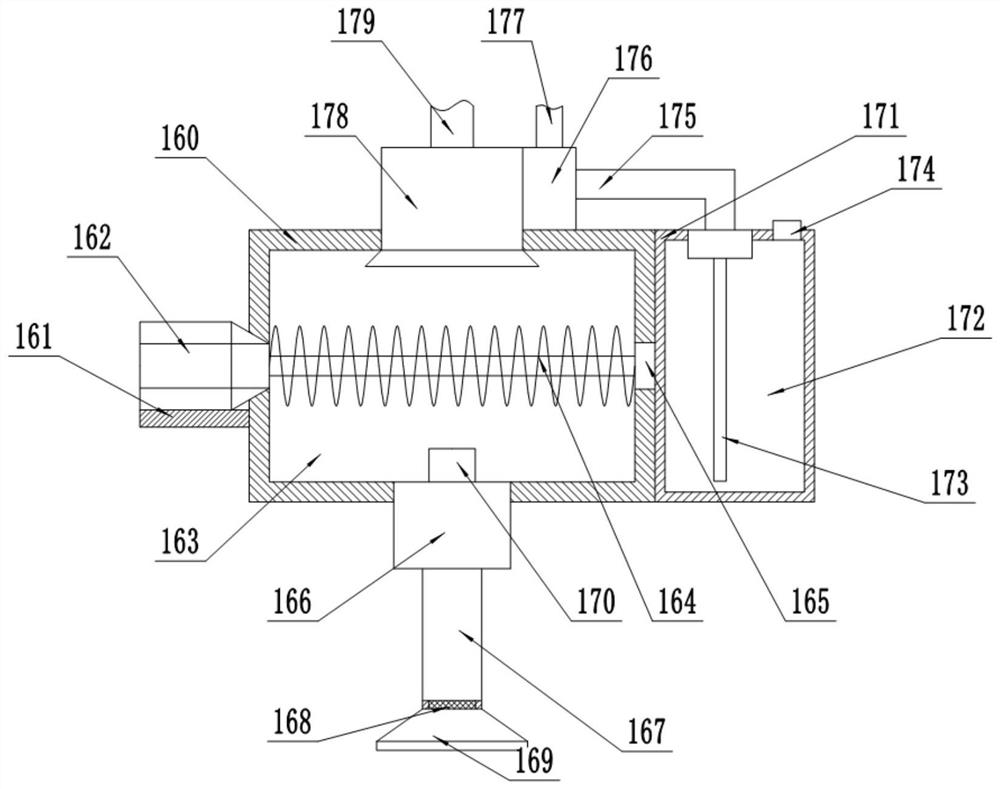

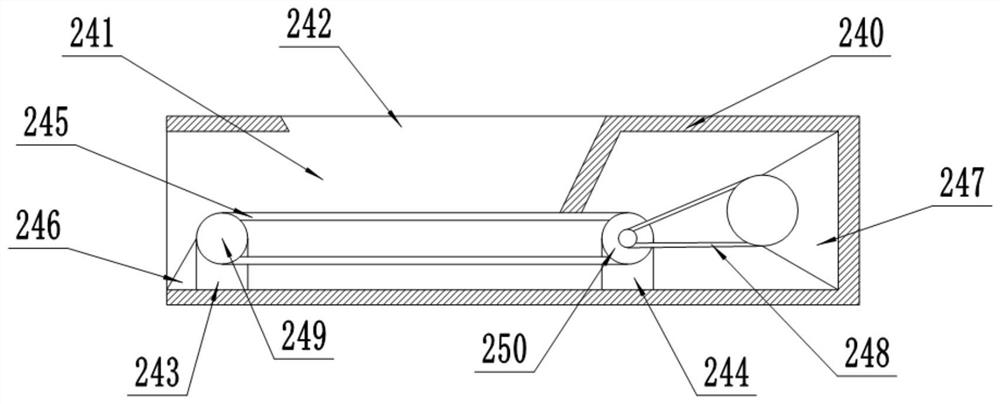

[0016] Such as figure 1As shown, this specific embodiment adopts the following technical solution: a hopper plaster connecting device for an automatic plastering machine. In order to solve the above problems, the present invention provides a technical solution: a The connecting device of the ash bucket wiper, including the plastering machine 1, the ash bucket wiper 2, the first wheel seat 3, the transverse pulley 4, the locking seat 5, the locking rod 6, the locking pad 7, and the first support column 8 , the first support base plate 9, the feeding box 10, the second wheel seat 11, the roller 12, the locking valve 13, the discharge plate 14, the handle of the feeding box 15, the stirring and cleaning device 16, the main pipe 17, the discharge cover 18, The first motor bottom plate 19, the first motor 20, the linkage rod 21, the limit hopper 22, the fixed bottom plate 23, the feeding device 24, the second support bottom plate 25, the second support column 26, the foot plate 27,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com