Partially-assembled sound insulation house and construction method

A prefabricated and housing technology, applied in the direction of sound insulation, insulating layer, protective building/shelter, etc., can solve the problems of low environmental pollution and poor integrity of prefabricated buildings, and achieve high land utilization, seismic performance and overall The effect of good performance and simple specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

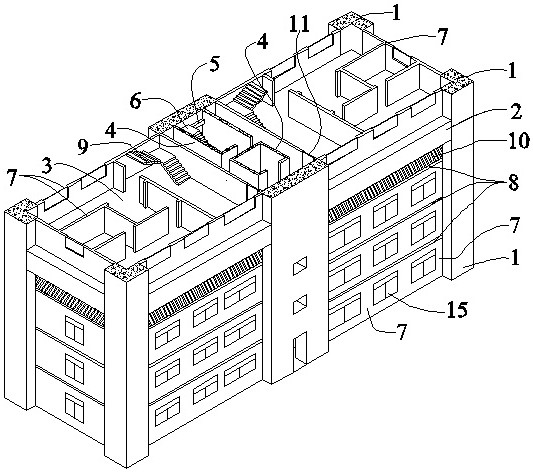

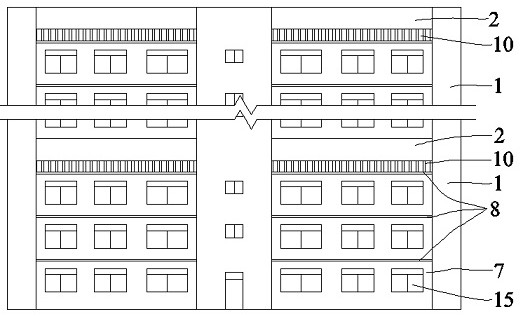

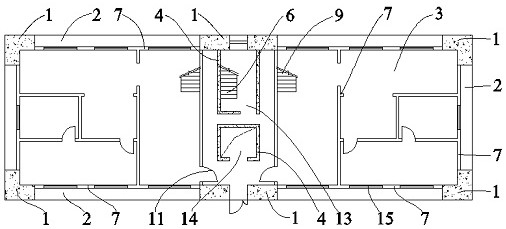

[0015] Such as Figure 1-Figure 4 As shown, a partially prefabricated soundproof house consists of giant columns (1), giant beams (2), cast-in-place floors (3), cast-in-place shear walls (4), cast-in-place ladder beams (5), stairs slab (6), prefabricated shear wall (7), laminated floor slab (8), interior staircase (9) and roof slab (10); giant column (1), giant beam (2), cast-in-place floor ( 3), cast-in-place shear walls (4) and cast-in-place ladder beams (5) are cast-in-place reinforced concrete components, stair slabs (6), prefabricated shear walls (7), indoor stairs (9) and roof slabs (10 ) is a prefabricated reinforced concrete component; the laminated floor (8) is composed of a prefabricated thin slab (81) and a cast-in-place slab (82), the prefabricated thin slab (81) is a prefabricated reinforced concrete component, and the cast-in-place slab (82) is a cast-in-place reinforced concrete Components; the giant beam (2) is supported on the giant column (1), and the cast-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com