a co 2 Micro blast combined with tbm rock breaking device

A rock-breaking device, CO2 technology, applied in mining equipment, tunnels, earth-moving drilling, etc., can solve the problems of uneven sealing of the face, affecting the installation of blasting pipes, etc., and achieves easy operation, improved continuity, and high construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

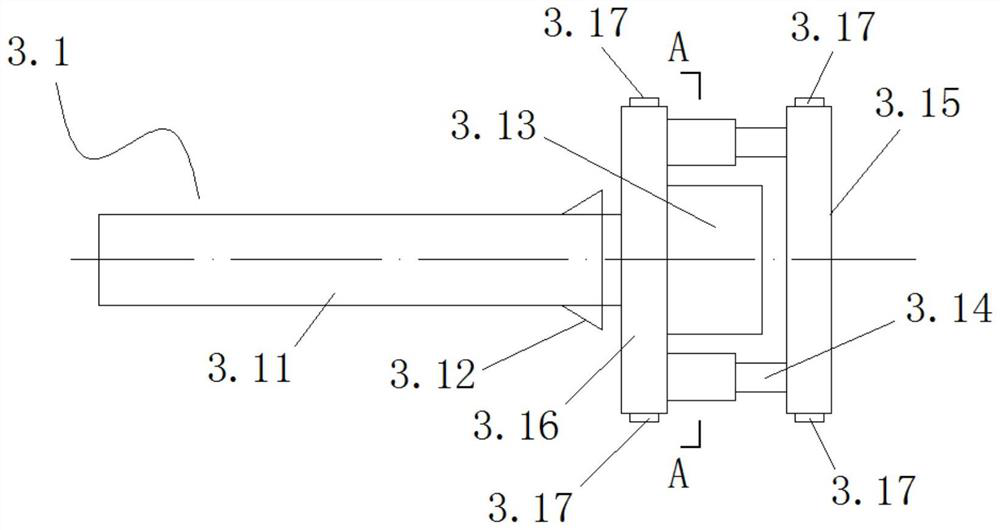

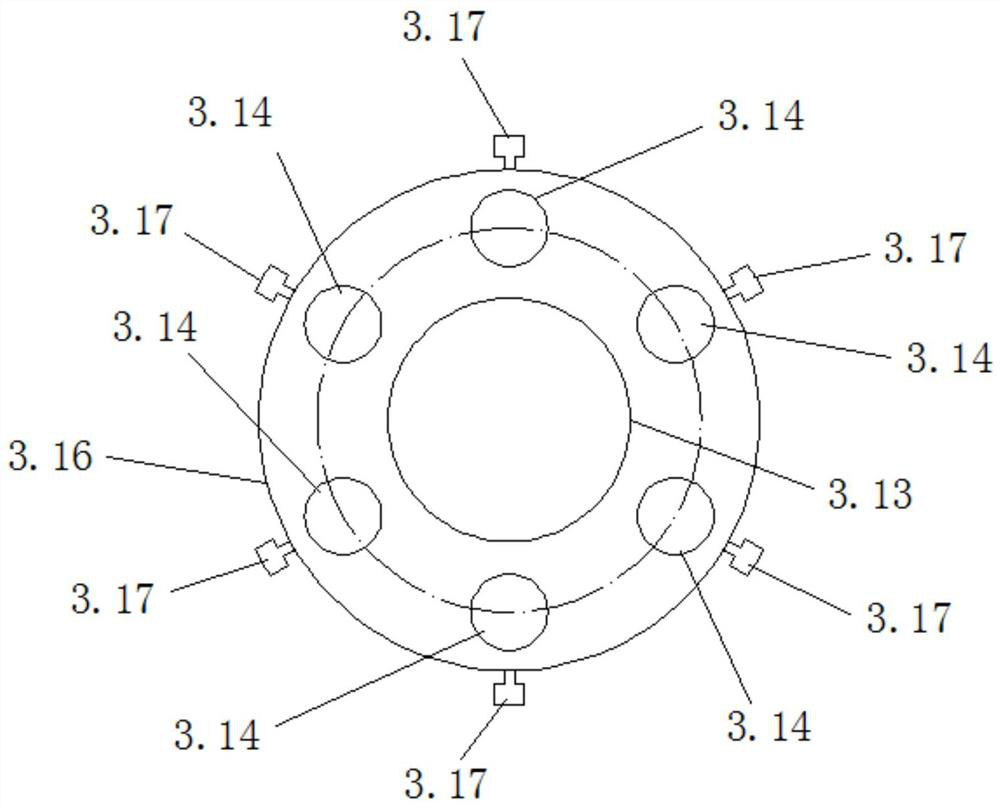

[0151] In this example, CO 2 Micro-explosion combined TBM rock breaking device 1 includes cutter head mechanism 2, drilling rig installation mechanism 3 and CO 2 Blasting device mounting mechanism 4; drilling rig mounting mechanism 3 and CO 2 The blasting device installation mechanism 4 is alternately arranged on the cutter head mechanism 2; the cutter head mechanism 2 is installed on the TBM main bearing; the belt conveyor 5 is installed on the support frame 6;

[0152] The cutterhead mechanism 2 includes a positive cutterhead 2.1 and a side cutterhead 2.2;

[0153] The side cutter head 2.2 is located on the outer periphery of the front cutter head 2.1;

[0154] Rig mounting cylinder 3.2 and CO of rig mounting mechanism 3 2 CO of blasting device installation mechanism 4 2 The installation cylinders 4.2 are alternately arranged on the positive cutter head 2.1;

[0155] The mechanical cutter 2.11 is arranged on the positive cutterhead 2.1; the side cutterhead 2.2 is equipp...

Embodiment 2

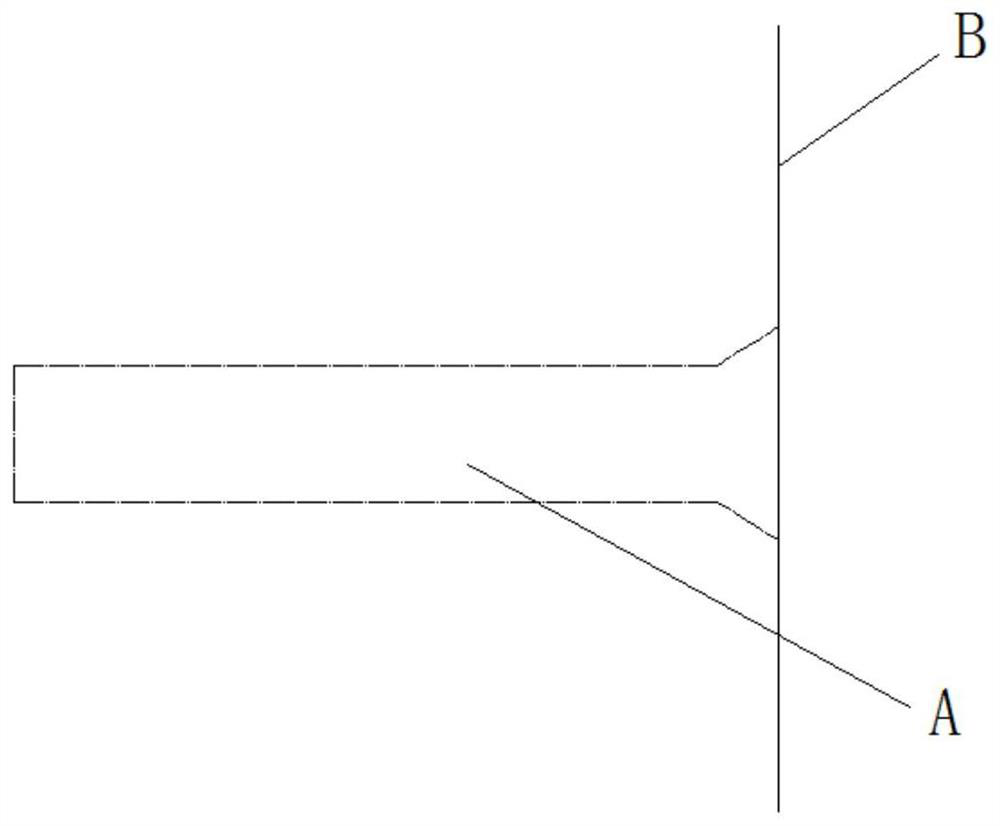

[0165] its CO 2 The micro-explosion combined TBM rock-breaking device 1 and its rock-breaking method are the same as in Embodiment 1, except that the rock mass in this embodiment is blasted and cut for a certain time, and the contour of the tunnel surface formed at last is not flat (as shown in Fig. 30), then there are differences in the strokes of the drilling rod of the drilling rig in the rock mass.

[0166] In this embodiment, a depth measurement sensor is set on the drilling rig (being the prior art); in this embodiment, the depth data of the actual drilling of the drilling rig is obtained by the depth measurement sensor on the drilling rig, and according to the depth data, the next stage CO 2 The filling amount of the blasting device and the length of the blasting tube are adjusted; Figure 30 , the actual working footage of the drilling rigs in area A is less than the actual working footage of the drilling rigs in area B, the adjustment method in this embodiment is: in...

Embodiment 3

[0168] its CO 2 Micro-explosion combined TBM rock-breaking device 1 and rock-breaking method thereof are the same as embodiment 2, the difference is that in this embodiment, the tunnel face contour line is an inclined structure or a rotating structure (such as Figure 31 shown); in Figure 31 Among them, the actual working footage of the drilling rigs in area C is greater than the actual working footage of drilling rigs in area D. The adjustment method in this embodiment is: when the TBM turns, the drilling length in area C is greater than that in area D. In the next stage, the state CO 2 When blasting the device, according to the depth of the borehole, the CO 2 The filling amount of gas is adjusted, that is, the area of C blasthole CO 2 Burst tube length and CO 2 The filling volume is larger than the D blast hole area.

[0169] Other unspecified parts belong to the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com