Air inlet net cleaning system of fan heater for smart home

A cleaning system, smart home technology, applied in separation methods, lighting and heating equipment, fluid heaters, etc., can solve the problems of underutilized waste heat, increased internal fan load, reduced life, etc., and achieve better shedding effect. , the effect of increasing the jitter frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

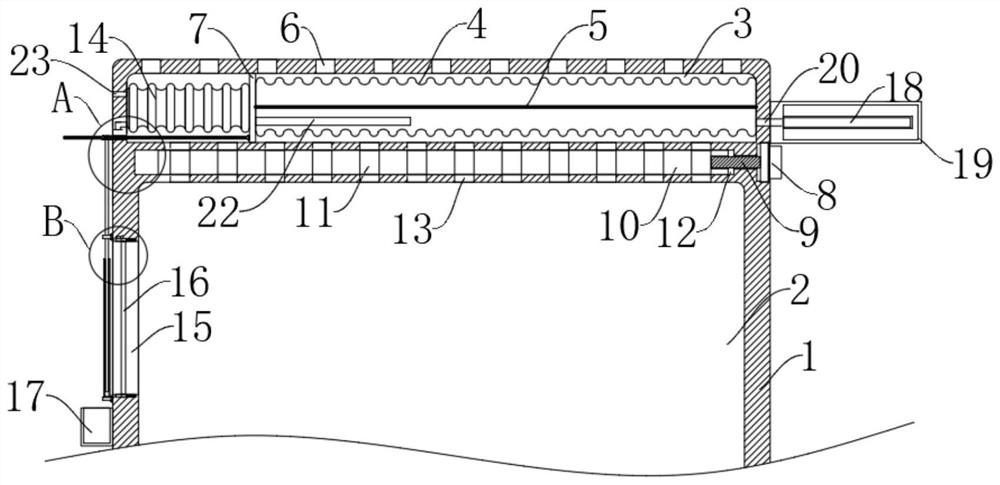

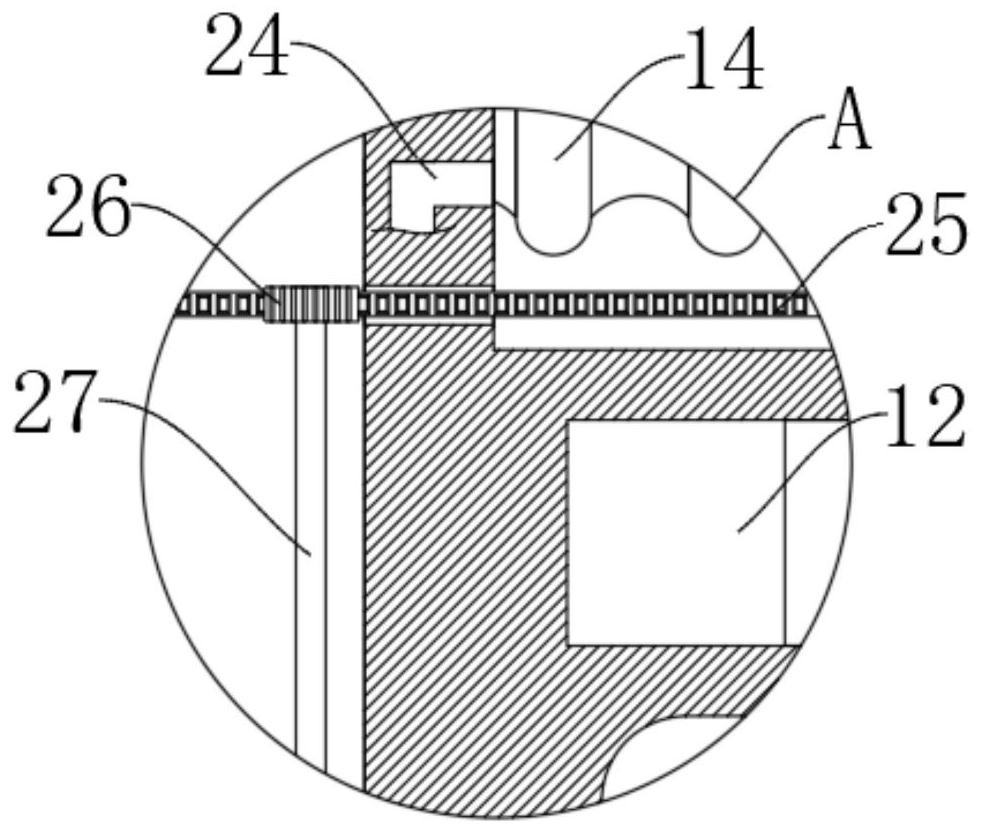

[0024] refer to Figure 1-4 , an air inlet net cleaning system for a smart home heater, comprising a heater body 1, the heater body 1 is provided with a reciprocating chamber 3, a sliding chamber 12 and a heating chamber 2 sequentially from top to bottom, and the left side of the heating chamber 2 An air inlet 15 is provided on the inner wall, and a filter screen 16 is installed in the air inlet 15. The inner top and inner bottom of the air inlet 15 are provided with chute 31, and both chute 31 are provided with sliders 32 for sliding left and right. , the right end of each slider 32 is slidably connected with the inner wall of the corresponding chute 31 through the connecting spring 33, and the opposite ends of the two sliders 32 all extend into the air inlet 15, and are fixedly connected with the upper and lower ends of the filter screen 16;

[0025] The conduction mechanism, the conduction mechanism includes a sliding bar 10 slidably connected in the sliding chamber 12, the...

Embodiment 2

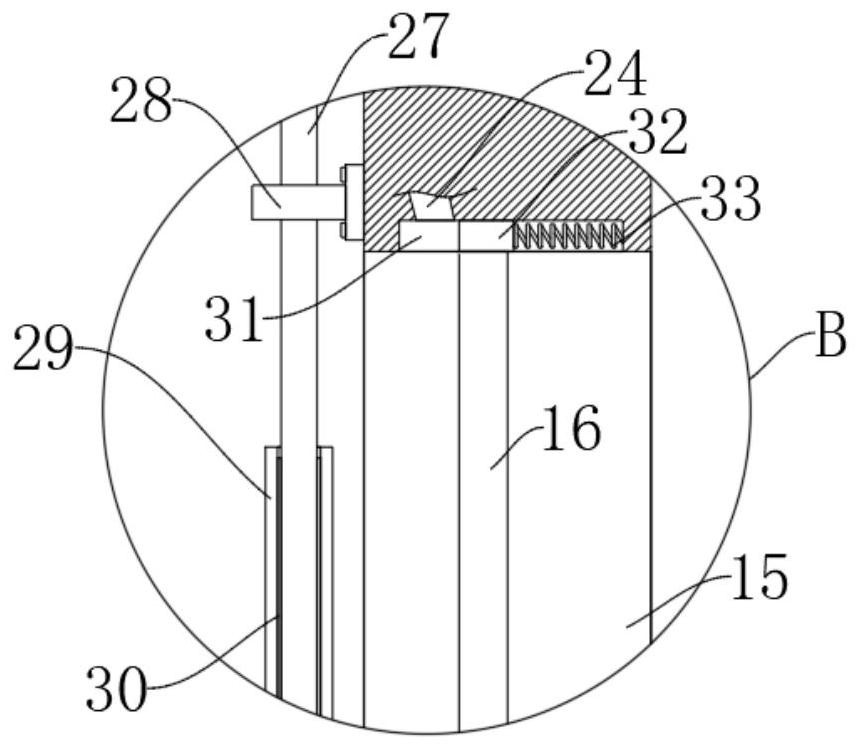

[0036] refer to Figure 5-6 , The difference between this embodiment and Embodiment 1 is that the left end of the filter screen 16 is fixedly connected to the block 21 , and the cam 35 that is fixed against the block 21 is sleeved on the rotating rod 27 .

[0037] In this embodiment, under the elastic action of the connecting spring 33, the block 21 and the cam 35 are always in contact with each other, and the rotation of the rotating rod 27 will make the filter screen 16 vibrate back and forth all the time, greatly increasing the vibration frequency of the filter screen 16, thereby making The shedding effect of dust on the filter screen 16 is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com