Baking equipment for curing forming of vacuum heat insulation board

A technology for curing molding and baking equipment, applied in lighting and heating equipment, drying, dryers and other directions, can solve the problems of inability to meet a variety of operation needs, single operation mode, large floor space, etc., to avoid heat The effect of heat dissipation, ease of use, and heat dissipation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

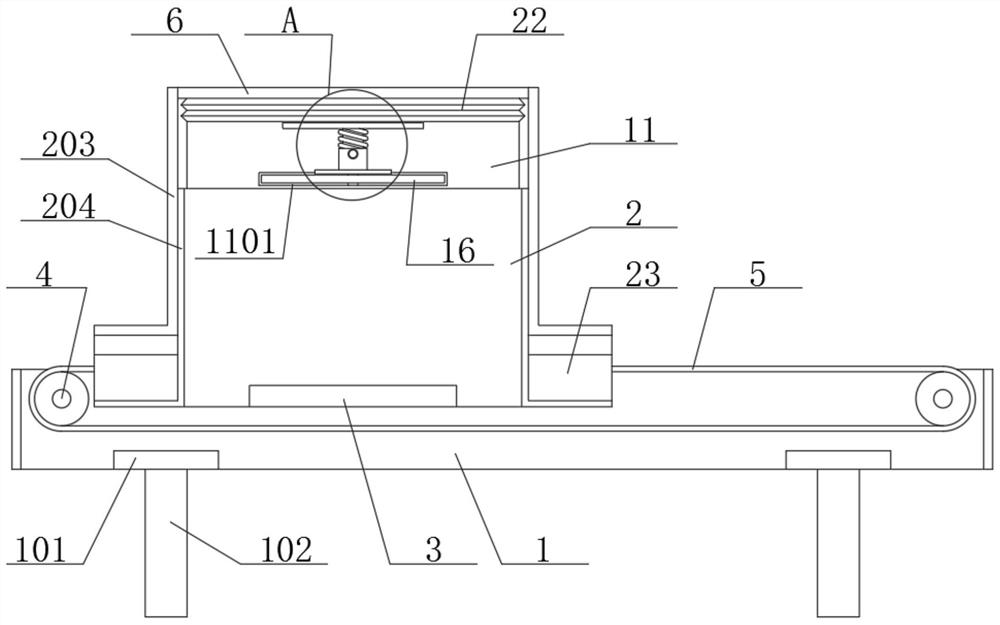

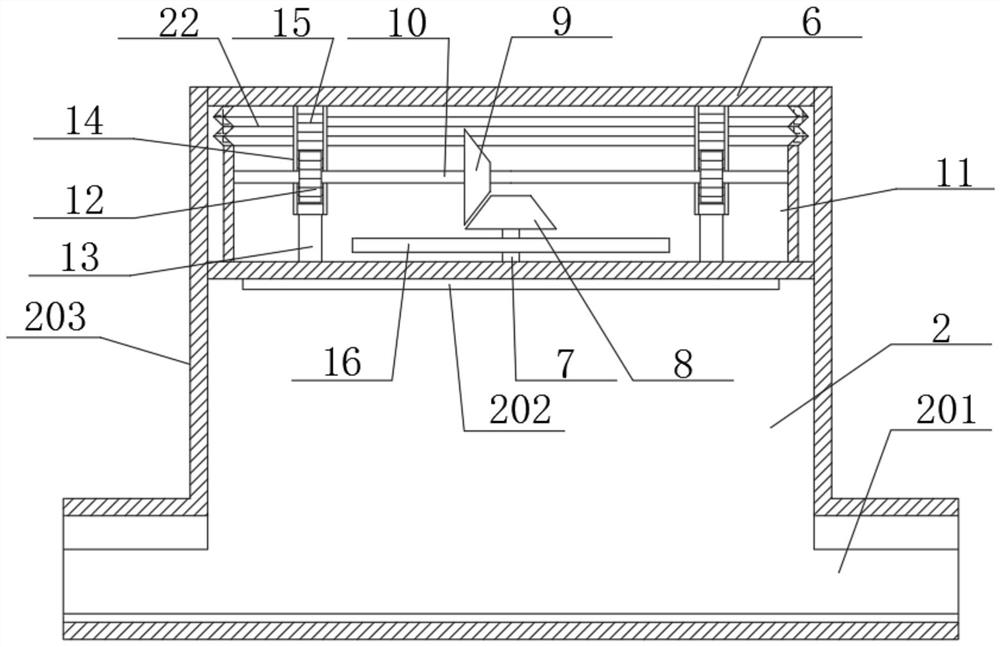

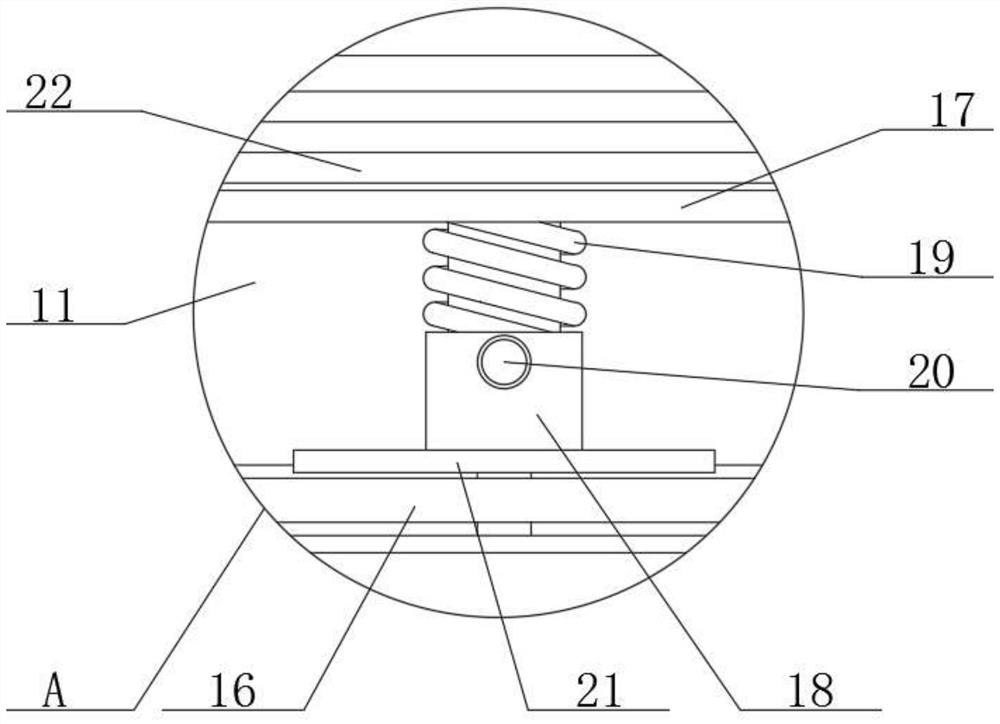

[0033] Such as Figure 1-5 As shown, a baking equipment for curing and molding of vacuum heat insulation boards includes a base shell 1, two first receiving rods 101 are connected to the inner wall of the base shell 1, and two first receiving rods 101 are connected to each of the first receiving rods 101. a supporting leg 102, the inside of the base shell 1 is provided with an oven 2, the oven 2 is connected with the base shell 1 through the second receiving rod 3, and the inner bottom wall of the oven 2 is coated with reflective paint,

[0034] The left and right ends of the oven 2 are provided with an extension section 201, and an L-shaped door panel 203 is arranged above the extension section 201. The inner top wall of the oven 2 is connected with a heating wire 202, and the inside of the base shell 1 is provided with two rollers 4, one roller 4 is connected to the inner wall of the base shell 1 through a driving device, and the other roller 4 is rotationally connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com