Bidirectional laminated shear soil box for vibration table test and use method

A shaking table test and lamination technology, which is used in vibration testing, testing material strength using a stable shear force, testing of machine/structural components, etc. Soil Earthquake Response, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

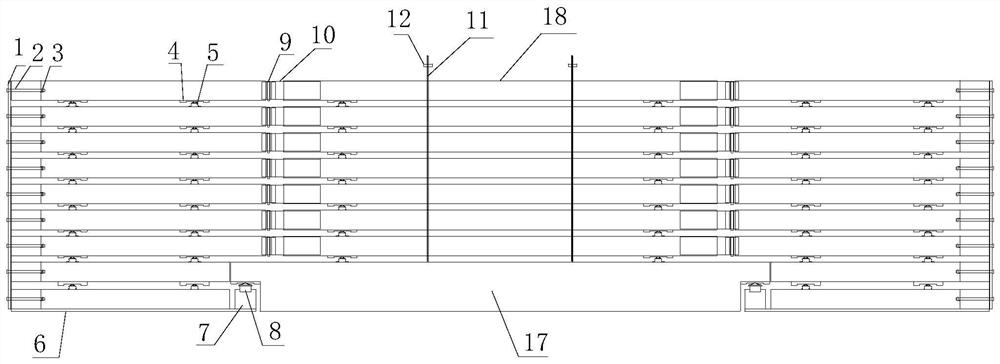

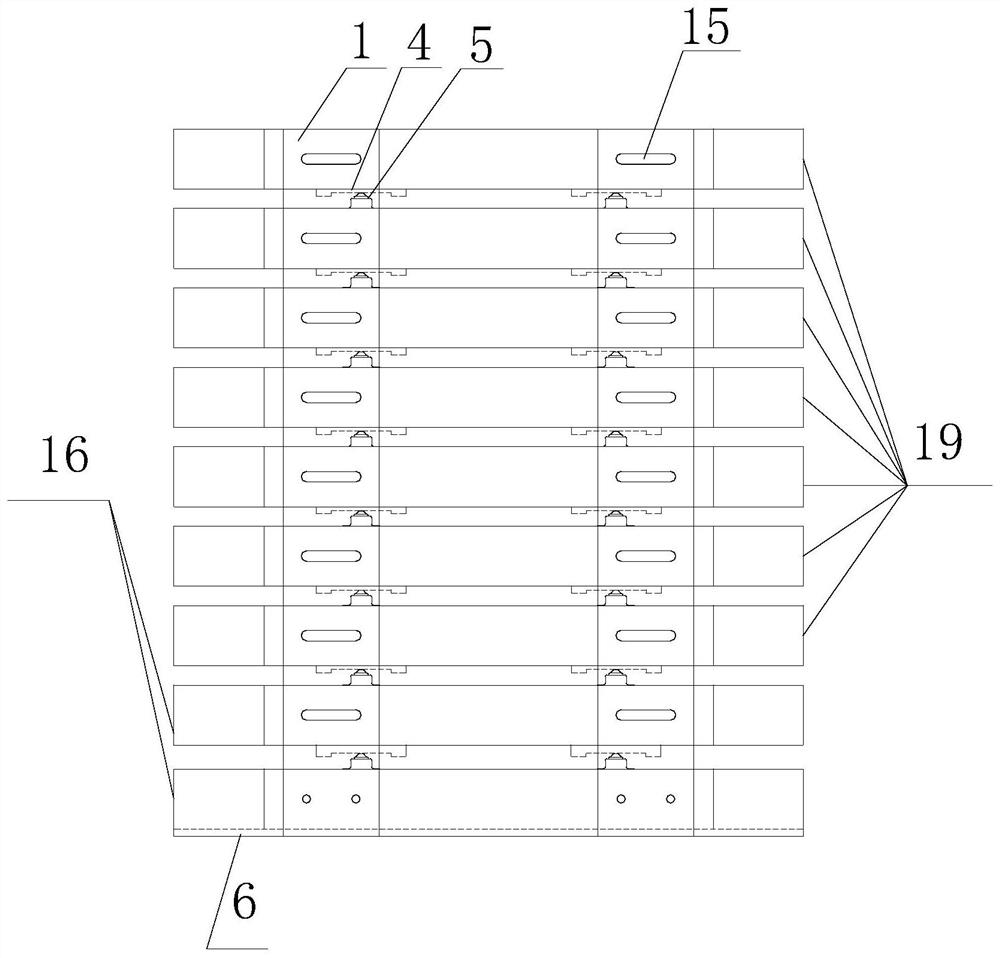

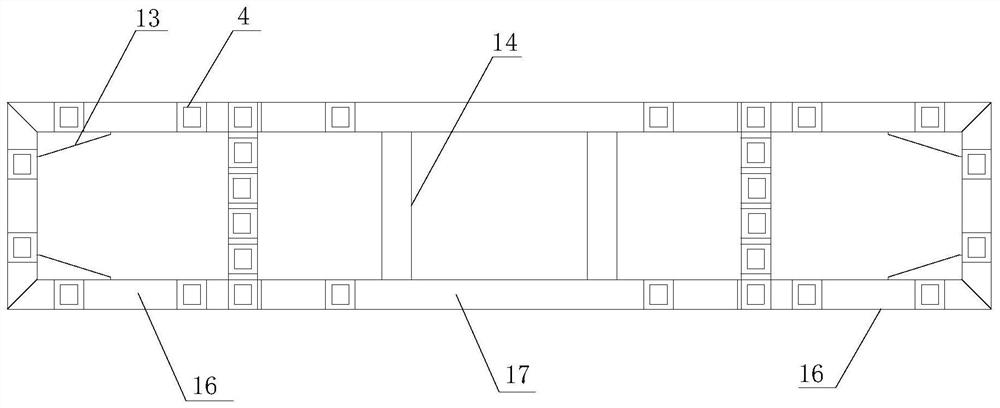

[0031]SeeFigure 1-4In this embodiment, the two-way laminated shear tank for the vibrating stage test includes a laminated frame casing, a rolling slip mechanism, a limit slip mechanism, and a telescopic mechanism; a stacked frame casing includes a support frame and The multilayer two-way U-box placed above the support box; between the support frame and the bidirectional U-box and between the adjacent two-layer bidirectional U-shaped frame are connected by a rolling slip mechanism; the rolling mechanism is multiple The telescopic mechanism is placed on a two-way U-shaped frame, which can meet the slip telescoping deformation brought by the bidirectional U-shaped frame; the limit slip mechanism is placed on the side wall of the laminated frame box, respectively, and realizes a laminated frame casing. Axial limit fixation and lateral slip.

[0032]Seefigure 1 withFigure 4 The two-way U-shaped frame provided in this embodiment includes two intermediate tubes 18 and two second U-shaped body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com