Connection mode of optical module and heat dissipation mechanism

A technology of heat dissipation mechanism and connection method, which is applied in the field of connection between optical modules and heat dissipation mechanisms, can solve problems such as increasing plugging resistance, affecting heat dissipation effect, and damaging the surface of optical modules, so as to reduce processing quality requirements and improve heat dissipation performance. , the effect of reducing operating resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

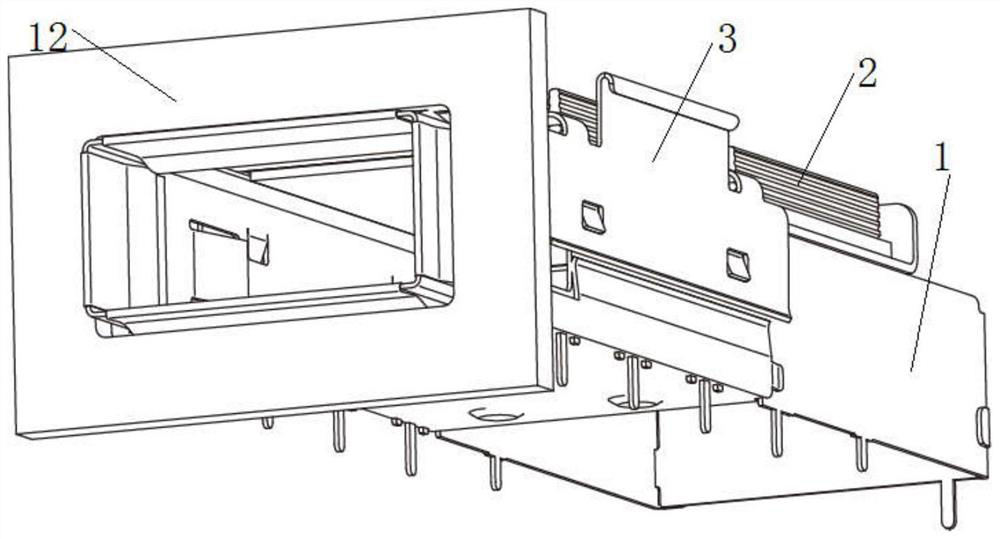

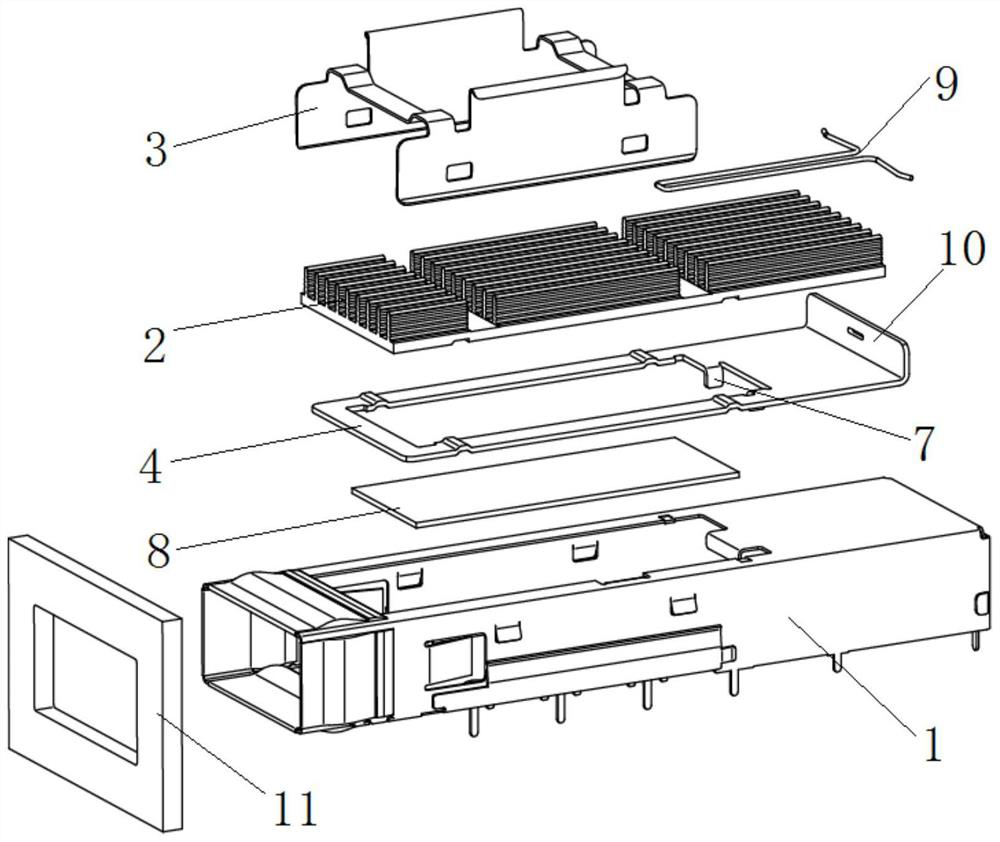

[0033] see Figure 1-2 , the embodiment of the present invention provides a connection method between an optical module and a heat dissipation mechanism. The heat dissipation mechanism includes a cage body. A cage radiator is hung outside the cage body through a spring clip. An adjustment mechanism is provided between the cage body and the cage radiator. The adjustment mechanism There is a reset mechanism on it. When the optical module is inserted into the cage body, it touches the adjustment mechanism and drives the adjustment mechanism to move horizontally, thereby causing the cage radiator to descend under the action of the spring clip. The bottom surface of the cage radiator contacts the optical module, and the optical module is pulled out from the cage body. , the adjustment mechanism can be reset under the action of the reset mechanism, so that the heat sink of the cage rises and separates from the optical module.

[0034] The entrance of the cage body is connected to t...

Embodiment 2

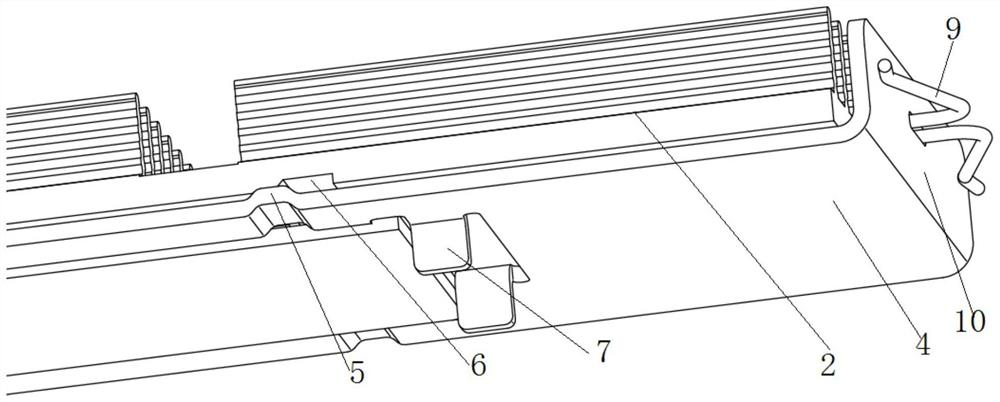

[0040] see Figure 5-6 , the embodiment of the present invention provides a connection method between an optical module and a heat dissipation mechanism. The heat dissipation mechanism includes a cage body. A cage radiator is hung outside the cage body through a spring clip. An adjustment mechanism is provided between the cage body and the cage radiator. The adjustment mechanism There is a reset mechanism on it. When the optical module is inserted into the cage body, it touches the adjustment mechanism and drives the adjustment mechanism to move horizontally, thereby causing the cage radiator to descend under the action of the spring clip. The bottom surface of the cage radiator contacts the optical module, and the optical module is pulled out from the cage body. , the adjustment mechanism can be reset under the action of the reset mechanism, so that the heat sink of the cage rises and separates from the optical module.

[0041]The entrance of the cage body is connected to th...

Embodiment 3

[0046] see Figure 7 , 8 , and the difference from Embodiment 1 is that in this embodiment, the reset device adopts a handle, and the handle is used for manual reset. The handle is arranged near the entrance of the cage, and a through hole is opened on the equipment panel for the handle to pass through.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com