Antarctic krill flavor peptide powder and preparation method thereof

An Antarctic krill and flavor technology, applied in the direction of food ingredients as taste improvers, food ingredients, protein food ingredients, etc., to achieve the effect of optimizing enzymatic hydrolysis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

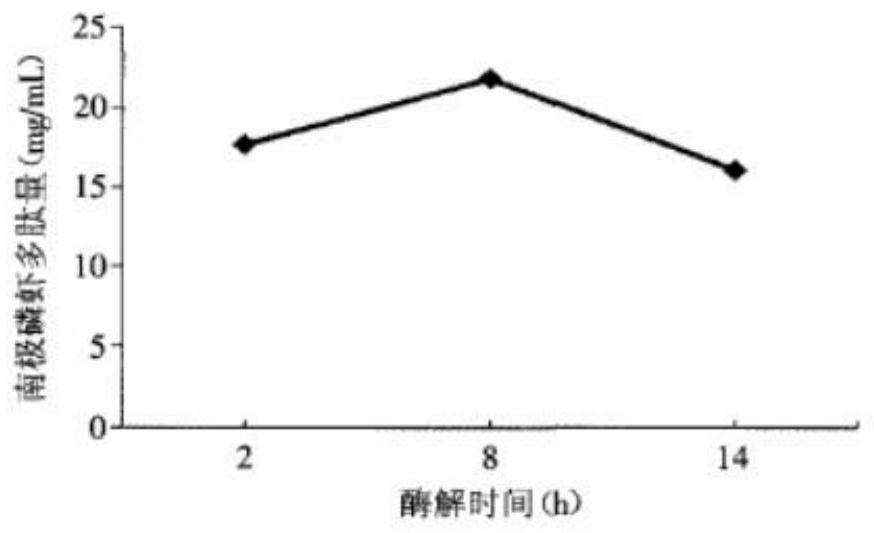

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of Antarctic krill flavor peptide powder, comprising the following steps:

[0027] (1) Weigh 200 g of shrimp powder and dissolve it in a ratio of 1:8. Take another 1600g of ultrapure water.

[0028] (2) Mix 200 g of shrimp meal with 600 g of ultrapure water and place it in a wall breaker to smash.

[0029] (3) The remaining 1000 g of ultrapure water was heated to 100°C, and stirring was started. Add the mixture spoon by spoon and keep stirring.

[0030] (4) When the temperature of all additions is constant to 55°C, start to measure and record the solid concentration.

[0031] (5) At this time, compound protease was added respectively, flavor protease 0.57g [two thousandths of the wet weight of the original shrimp (30%), namely: 200 / 0.7*0.002] (more or less).

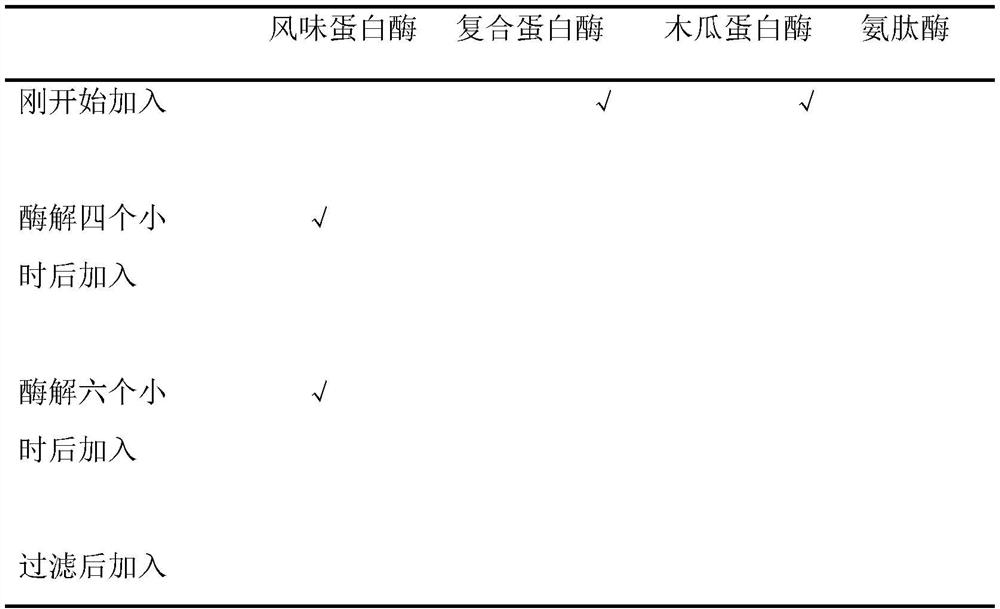

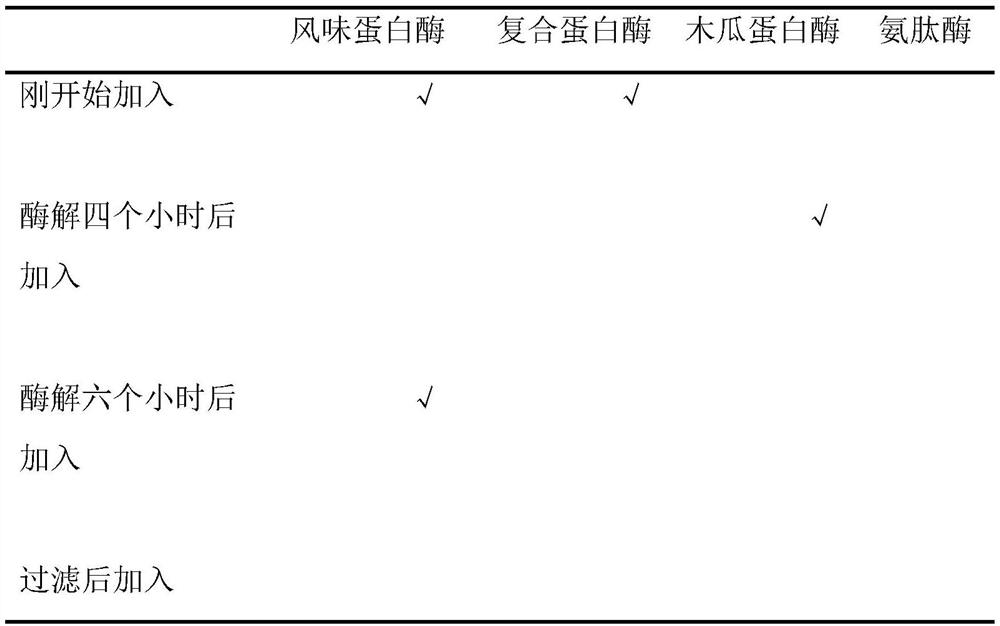

[0032] (6) After four hours of enzymatic hydrolysis, papain (0.57 g) was added to continue enzymatic hydrolysis for two hours, and flavor protease and aminopeptidase (0.57 g) were added af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com