Method for preparing collagen from deer sinew

A technology of deer tendon collagen and deer tendon, applied in the field of collagen purification, can solve the undiscovered problems of collagen extraction process research and reporting, and achieve the effects of stable experimental results, short enzymatic hydrolysis time and mild enzymatic hydrolysis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

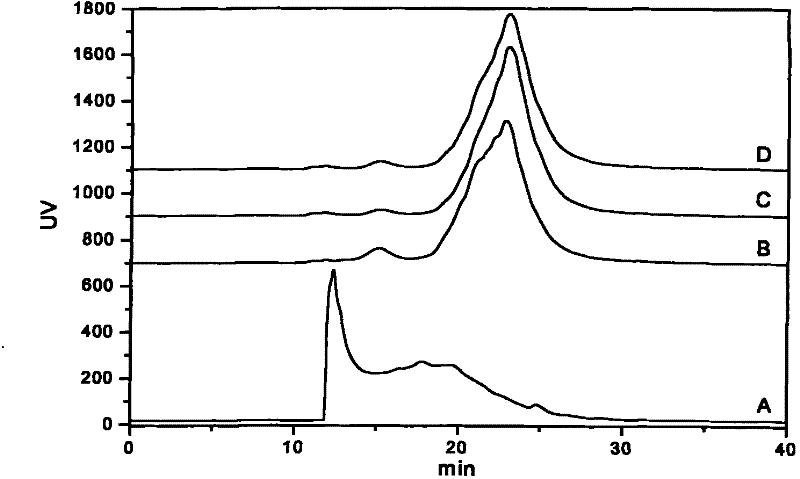

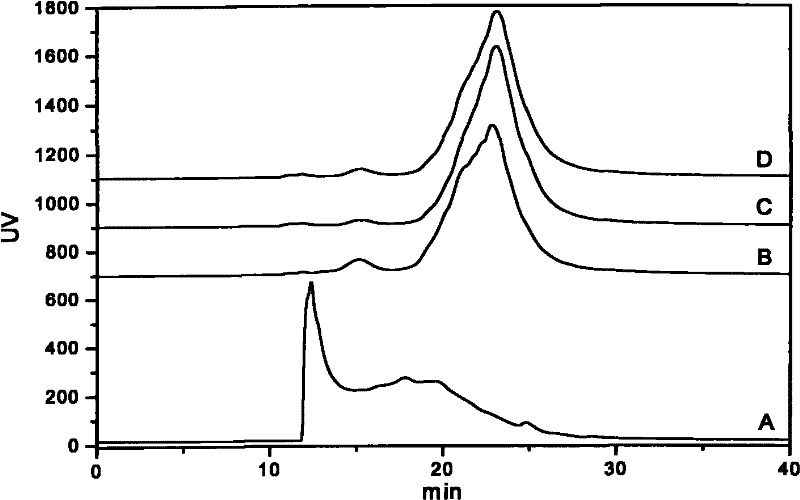

Image

Examples

Embodiment 1

[0033] 1) After removing the fat, skin and fascia from fresh deer tendons, cut them into 0.5~1cm 3 Use 0.9% normal saline to repeatedly clean the small pieces of serum and fat, then rinse with distilled water, and store in a refrigerator at -20°C. The moisture content is about 65%;

[0034] 2) Take 30g of fresh deer tendon processed above, add 300ml, 0.1% volume concentration of hydrochloric acid solution according to the material-to-liquid ratio of 1g: 10ml, and put it in the refrigerator at 4℃ for 12 hours to make deer tendon absorb acid water and acid swell, 12 hours Afterwards, take out the deer tendons and place them in boiling water at 100°C until the deer tendons are completely dissolved. The time required is 75min. Then filter with gauze with absorbent cotton, centrifuge the filtrate (12000rpm / min, 30min), discard the precipitate, and save the supernatant. ;

[0035] 3) Add 1M NaOH solution to the supernatant to adjust the pH to 7.0, centrifuge (12000rpm / min, 30min), discar...

Embodiment 2

[0041] 1) After removing the fat, skin and fascia from fresh deer tendons, cut them into 0.5~1cm 3 Use 0.9% normal saline to repeatedly clean the small pieces of serum and fat, then rinse with distilled water, and store in a refrigerator at -20°C. The moisture content is about 65%;

[0042] 2) Take 30g of the fresh deer tendon processed above, add 0.2% hydrochloric acid solution at a material-to-liquid ratio of 1g: 10ml and place it in a refrigerator at 4°C for 36 hours to make the deer tendon absorb acid water and acid swell. Take out the deer tendon after 36 hours Place it in boiling water at 100°C until the deer tendon is completely dissolved. The time required is 55 minutes, then filter with gauze with absorbent cotton, centrifuge the filtrate (12000rpm / min, 30min), discard the precipitate, and save the supernatant;

[0043] 3) Add 1M NaOH solution to the supernatant of step 2) to adjust the pH to 7.0, centrifuge (12000rpm / min, 30min), discard the precipitate, and retain the sup...

Embodiment 3

[0049] 1) After removing the fat, skin and fascia from fresh deer tendons, cut them into 0.5-1cm 3 Use 0.9% normal saline to repeatedly clean the small pieces of serum and fat, then rinse with distilled water, and store in a refrigerator at -20°C. The moisture content is about 65%;

[0050] 2) Take 30g of the fresh deer tendon processed above, add 0.8% hydrochloric acid solution at a material-to-liquid ratio of 1g:15ml and place it in a refrigerator at 4°C for 60 hours to make the deer tendon absorb acid water and acid swell. Take out the deer tendon after 60 hours Place it in boiling water at 100°C until the deer tendon is completely dissolved, the time is 32 minutes, then filter with gauze with absorbent cotton, centrifuge the filtrate (12000rpm / min, 30min), discard the precipitate, and save the supernatant;

[0051] 3) Add 1M KOH solution to the gelatin solution in step 2) to adjust the pH to 7.0, centrifuge (12000rpm / min, 30min), discard the precipitate and retain the supernatan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com