Composite phase change temperature control material based on expanded graphite and non-woven fabric and preparation method of composite phase change temperature control material

A technology of expanded graphite and composite phase change, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of easy leakage, temperature-controlled non-woven composite materials are fragile, etc., and achieve high thermal conductivity and phase transition temperature. Stable, structurally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A preparation method of a composite phase change temperature control material based on expanded graphite and non-woven fabric, comprising the following steps:

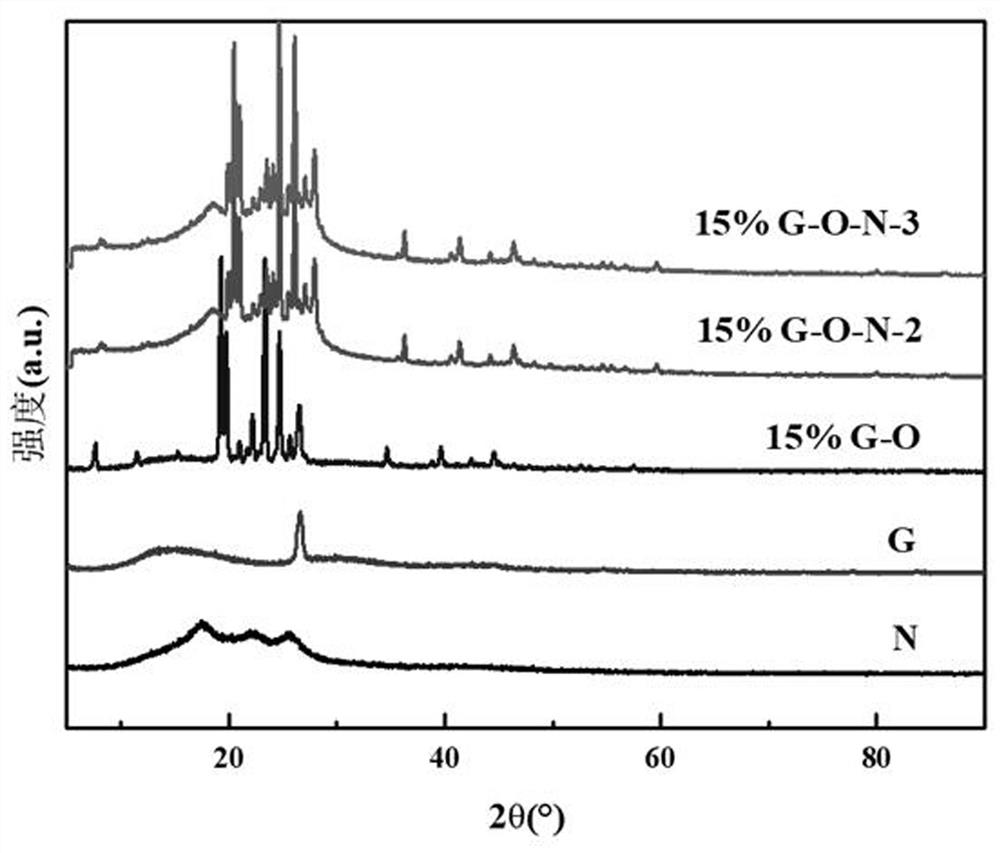

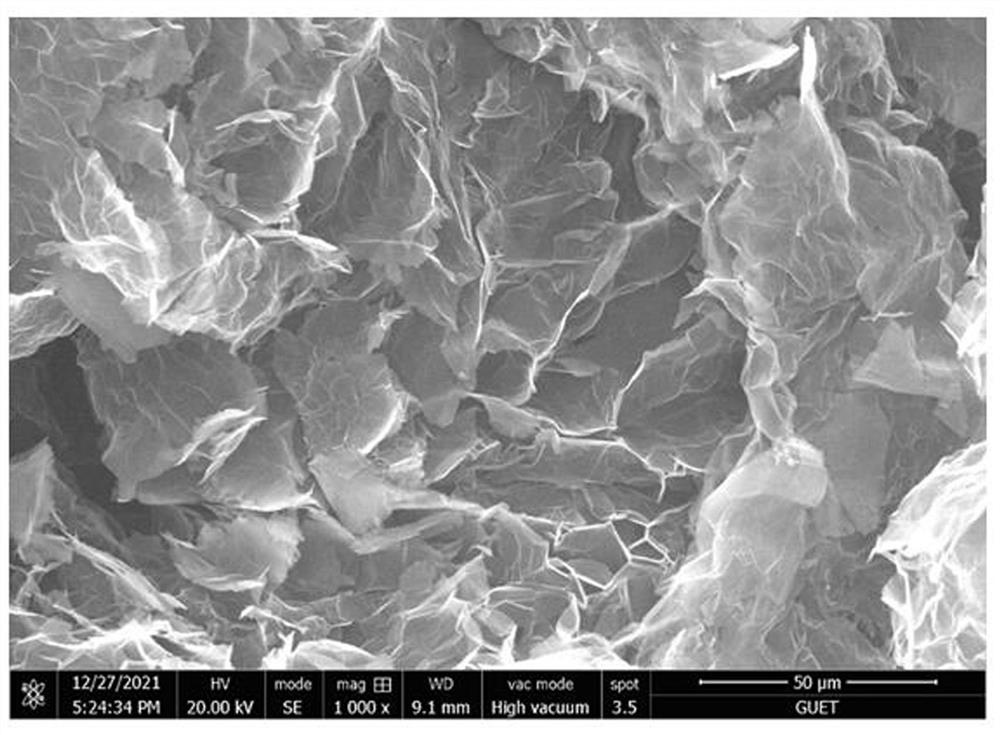

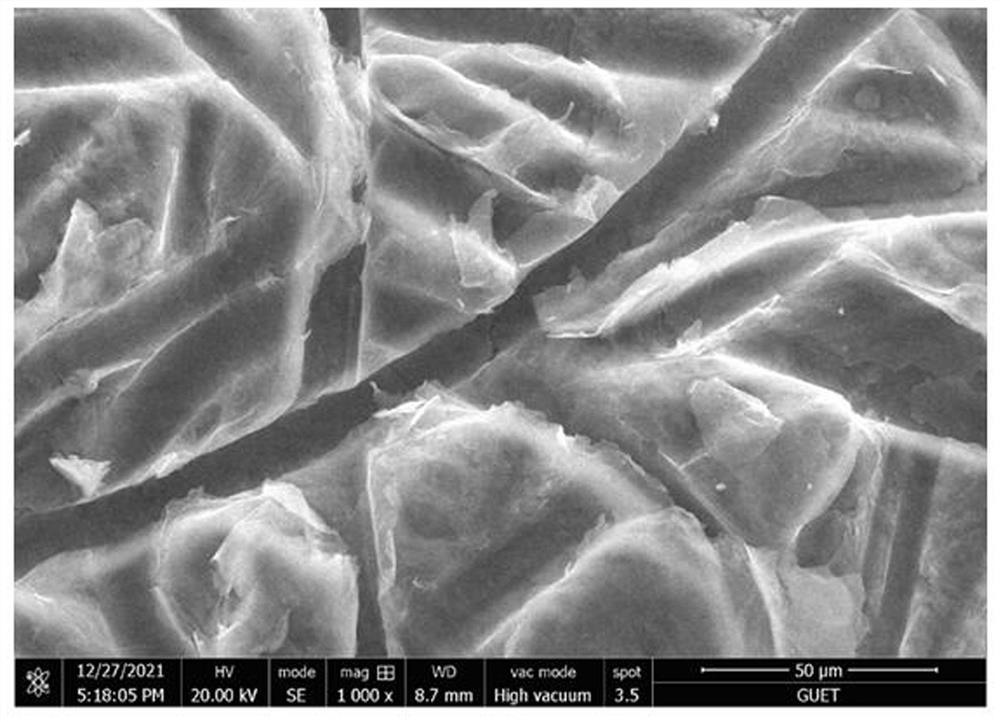

[0066] Step 1, the preparation of expanded graphite G and n-octadecane Oct composite material, firstly, under the condition that the treatment temperature is 950 °C and the treatment time is 30 s, the graphite is treated into expanded graphite, and then n-octadecane and expanded graphite are used to satisfy the conditions of The mass ratio is 17:3 for mixing treatment. The specific treatment method is as follows: under the condition of 60 °C, n-octadecane is added dropwise to the expanded graphite and stirred to disperse evenly. Then, the heating temperature is 60 °C, and the heating time is The expanded graphite and n-octadecane composite material can be obtained by vacuum adsorption under the condition of 24 h, abbreviated as 15% G-O;

[0067] Step 2, the preparation of composite phase change temperature contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat storage density | aaaaa | aaaaa |

| heat storage density | aaaaa | aaaaa |

| heat storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com