A kind of three-dimensional network chitosan sustained-release coating and preparation method thereof

A three-dimensional mesh, chitosan technology, used in coatings, prostheses, medical sciences, etc., can solve the problems of low bonding strength of hydrogel coatings and base materials, unable to adhere firmly, and achieve easy chemical The effect of modification, high production efficiency and simple experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

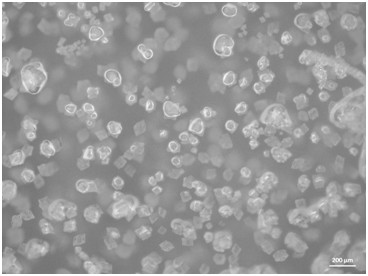

[0029] Dissolve 1 g of chitosan powder in 100 ml of 1% (v / v) acetic acid solution to obtain a 1% (w / v) chitosan solution, add dropwise uniformly to the prepared chitosan solution Methacrylic anhydride (the molar ratio of acid anhydride to amino group is 2:1), the entire reaction system is maintained at a constant speed from beginning to end and heated in a 60°C water bath for 12 h, and the reacted solution is adjusted to medium with sodium bicarbonate. The chitosan derivative solution prepared above was put into a dialysis bag and dialyzed in the environment of deionized water for 4 to 5 days to remove unreacted substances, and 0.2 wt% I2959 was added to the CSMA prepolymer solution. Photoinitiator with appropriate amount of 4 MCaCl 2 The solution was mixed by a magnetic stirrer, and then irradiated with low-dose UV light for 10 min to successfully construct a CSMA hydrogel coating.

Embodiment 2

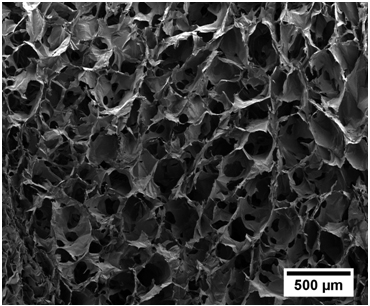

[0031] Dissolve 1 g of chitosan powder in 100 ml of 1% (v / v) acetic acid solution to obtain a 1% (w / v) chitosan solution, add formazan dropwise to the prepared chitosan solution at a uniform rate. base acrylic anhydride (the molar ratio of acid anhydride to amino group is 2:1), the entire reaction system was kept stirring at a constant speed from beginning to end and heated in a water bath at 60°C for 12 h, and the solution after the reaction was adjusted to neutrality with sodium bicarbonate The pH is for standby use. The chitosan derivative solution prepared above is put into a dialysis bag and dialyzed in the environment of deionized water for 4 to 5 days to remove unreacted substances. 0.2 wt% I2959 photoinitiator was added to the CSMA prepolymer solution, mixed with a magnetic stirrer, and then irradiated with low-dose UV light for 10 min to successfully construct the CSMA hydrogel coating.

Embodiment 3

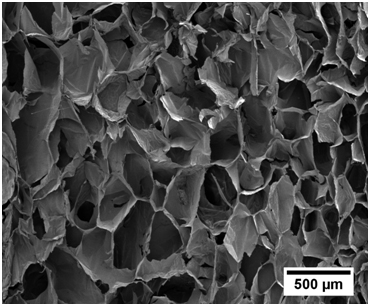

[0033] Dissolve 1 g of chitosan powder in 100 ml of 1% (v / v) acetic acid solution to obtain a 1% (w / v) chitosan solution, add formazan dropwise to the prepared chitosan solution at a uniform speed. base acrylic anhydride (the molar ratio of acid anhydride to amino group is 2:1), the entire reaction system was kept stirring at a constant speed from beginning to end and heated in a water bath at 60°C for 12 h, and the solution after the reaction was adjusted to neutrality with sodium bicarbonate The pH value was set aside, the chitosan derivative solution prepared above was put into a dialysis bag and dialyzed in the environment of deionized water for 4 to 5 days to remove unreacted substances, and 0.2 wt% I2959 light was added to the CSMA prepolymer solution. Initiator and appropriate amount of 4M CaCl 2 The solution was mixed by a magnetic stirrer, and then irradiated with low-dose UV light for 10 min, and the hydrogel coating was placed in a device containing ammonium carbona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com