Brush head forming device with inner core

A molding device and inner core technology, which is applied to brushes, brush bodies, household appliances, etc., can solve the problems of low production efficiency of products, and achieve the effects of improving production efficiency, reducing movement precision, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

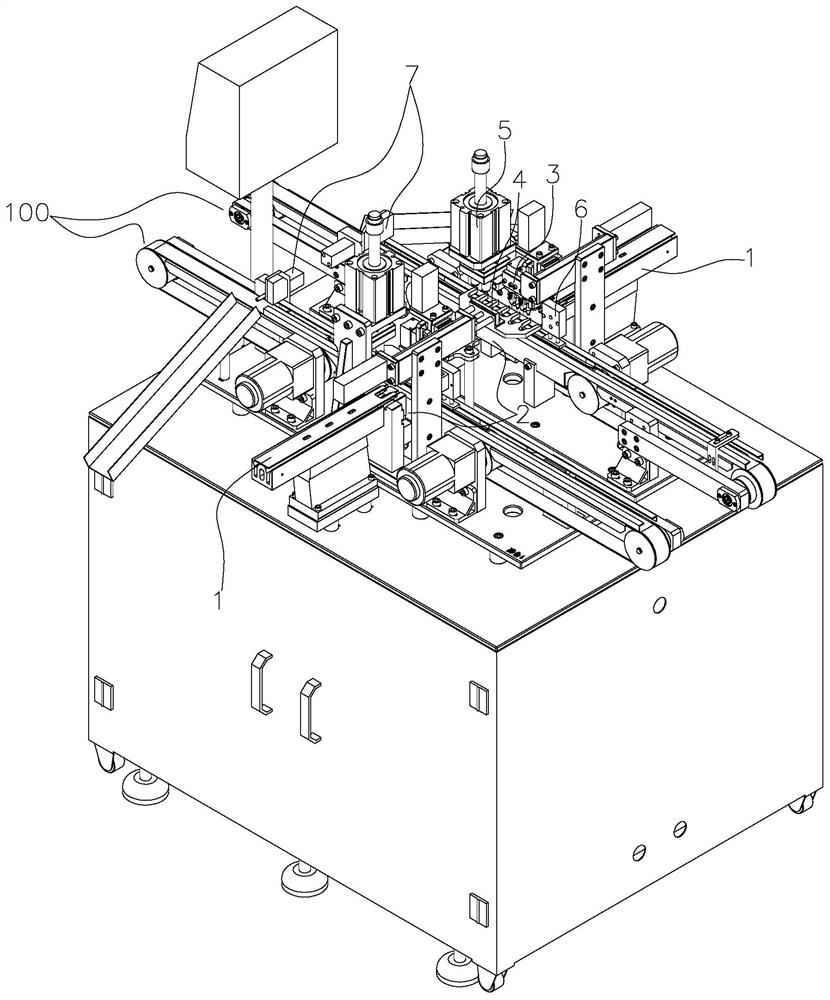

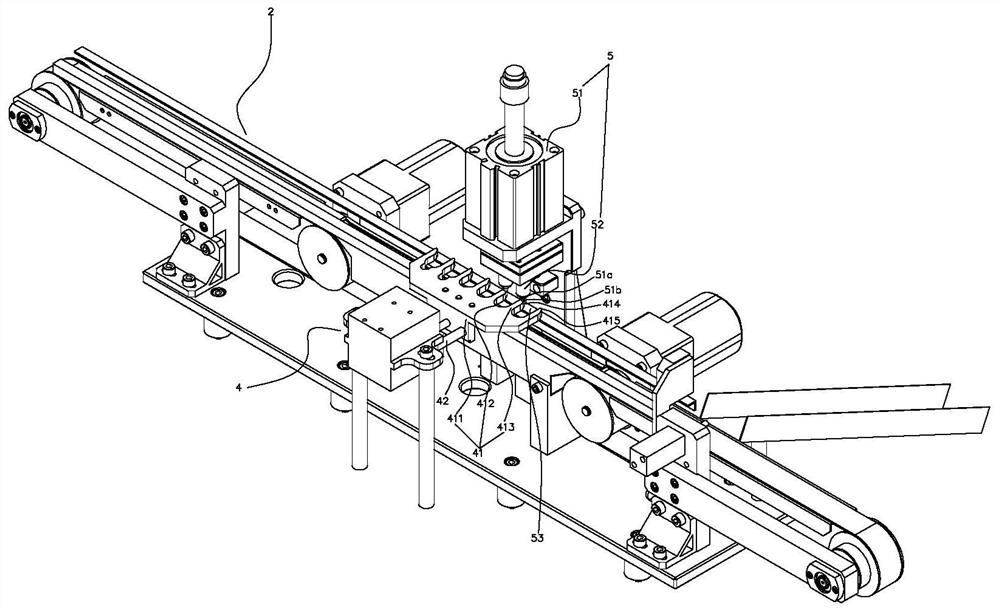

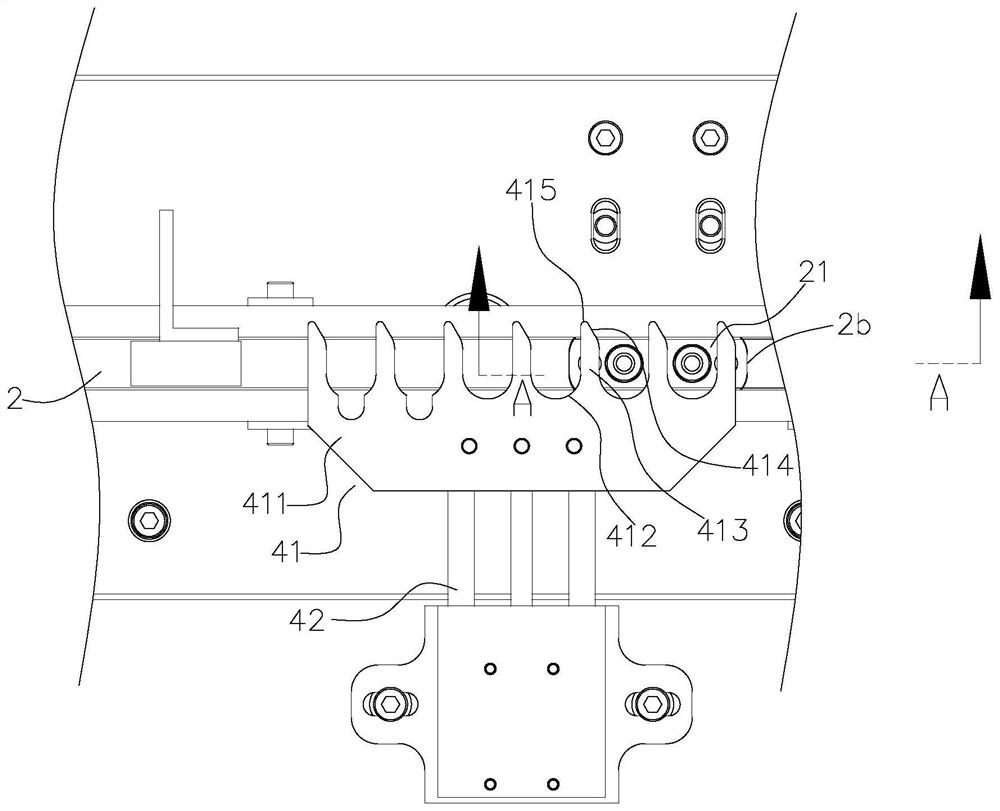

[0042] refer to Figure 1 to Figure 13 , the present embodiment provides a brush head forming device with an inner core, including a frame and a first conveying line 100 arranged on the frame, the first conveying line 100 is preferably provided with two or more, and can also be used alone The first conveying line 100 includes the first feeder 1 which is arranged on the frame and is used for conveying the inner core of the brush head, the second feeder 2 for inputting the brush head, and the first feeder 1 for the brush head The transfer device 3 for transferring the upper inner core to the second feeder 2, the limiting device 4 for limiting the inner core on the second feeder 2, and the pressing for pressing the inner core on the second feeder 2 device 5, the transfer device 3 is located between the first feeder 1 and the second feeder 2, the limit ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap