Hydraulic oil filtering device utilizing negative pressure

A hydraulic oil filtration and negative pressure technology, which is applied in the field of hydraulic oil filtration, can solve problems such as the inability to judge the state of the filter element, broken hydraulic oil pipes, and complex structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

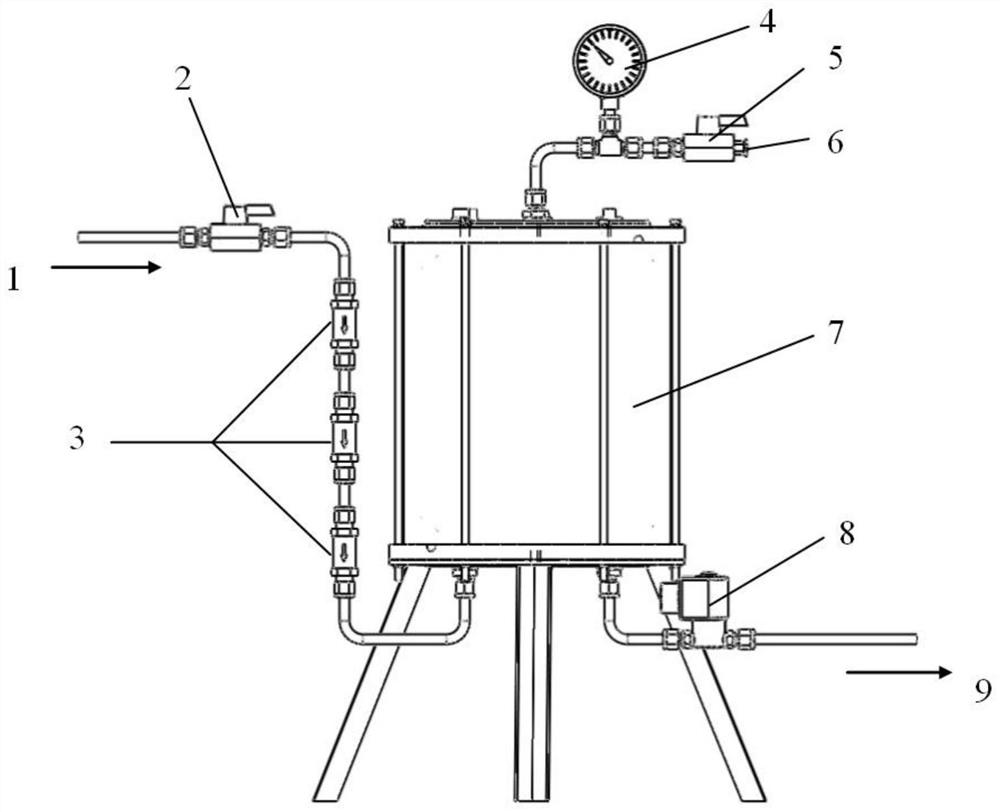

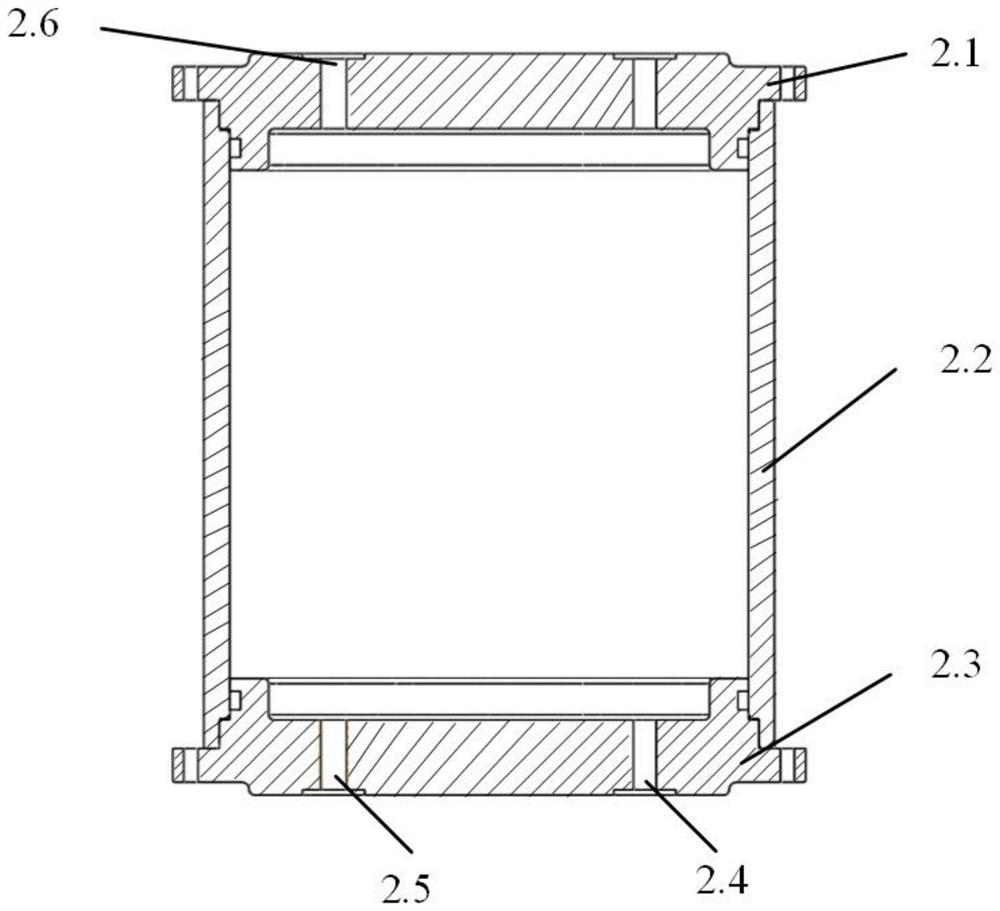

[0011] A hydraulic oil filter device using negative pressure, such as figure 1 and figure 2 As shown, a negative pressure oil tank 7 is provided, and the negative pressure oil tank 7 is provided with an upper end cover 2.1, a lower end cover 2.3 and a tank body 2.2; Connect with the pneumatic joint 6 in sequence; the lower end cover 2.3 of the negative pressure oil tank 7 is provided with an oil suction port 2.4 and an oil discharge port 2.5, and the oil suction port 2.4 is connected with the filter 3 and the hand valve 2 in sequence, and there are 3 filters 3; the oil discharge port 2.5 is connected to the solenoid valve 8; the two end caps of the negative pressure oil tank 7 and the tank body 2.2 are sealed with an O-ring; the hydraulic oil enters the filter system from the oil inlet 1, and enters the filter system after being filtered by the three-stage filter 3 Store in the negative pressure oil tank 7.

[0012] When starting to filter, first connect the oil inlet 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com