Multi-stage injection type water-soluble waste gas recovery system and waste gas recovery process

A waste gas recovery and spraying technology, which is applied in the direction of dispersed particle filtration, transportation and packaging, and dispersed particle separation, can solve the problems of poor solution, waste, solution waste, etc., and achieve accurate measurement results, full response, and avoid solution waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

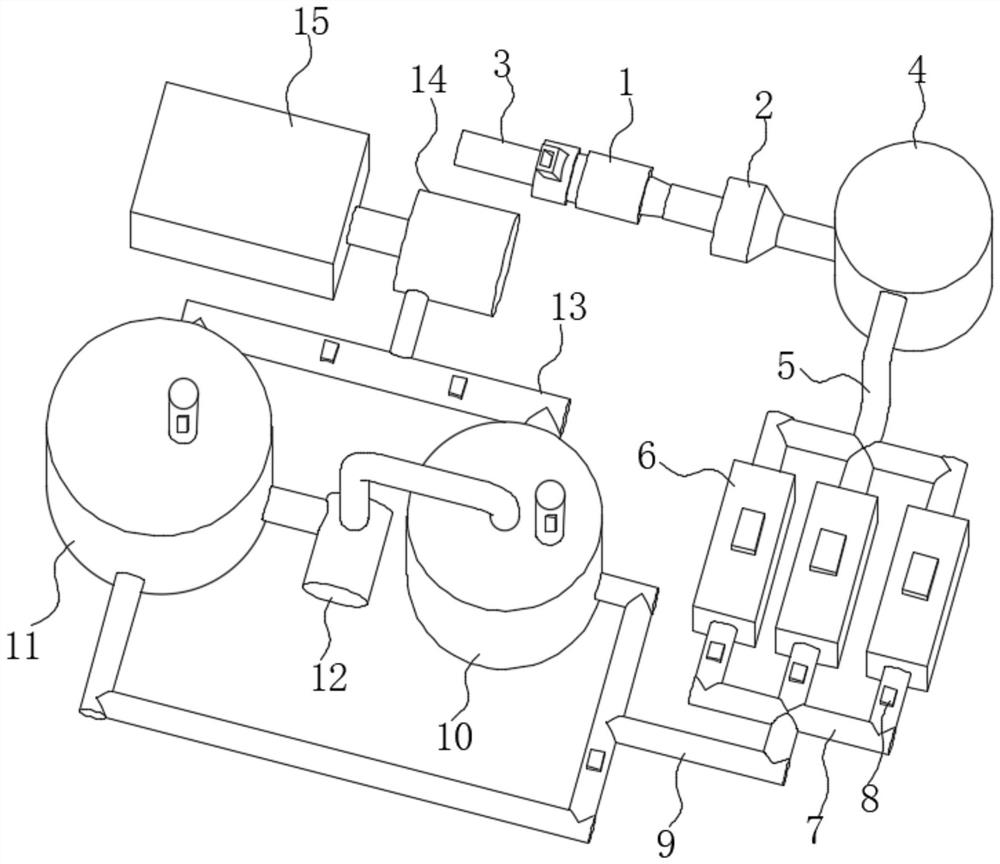

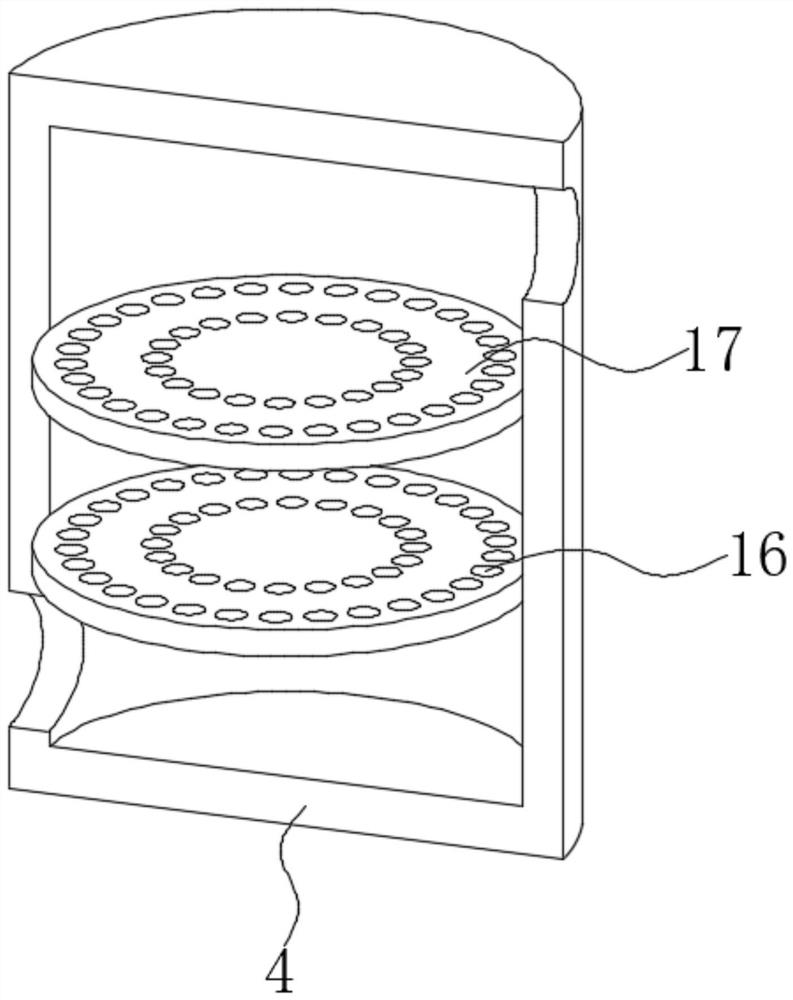

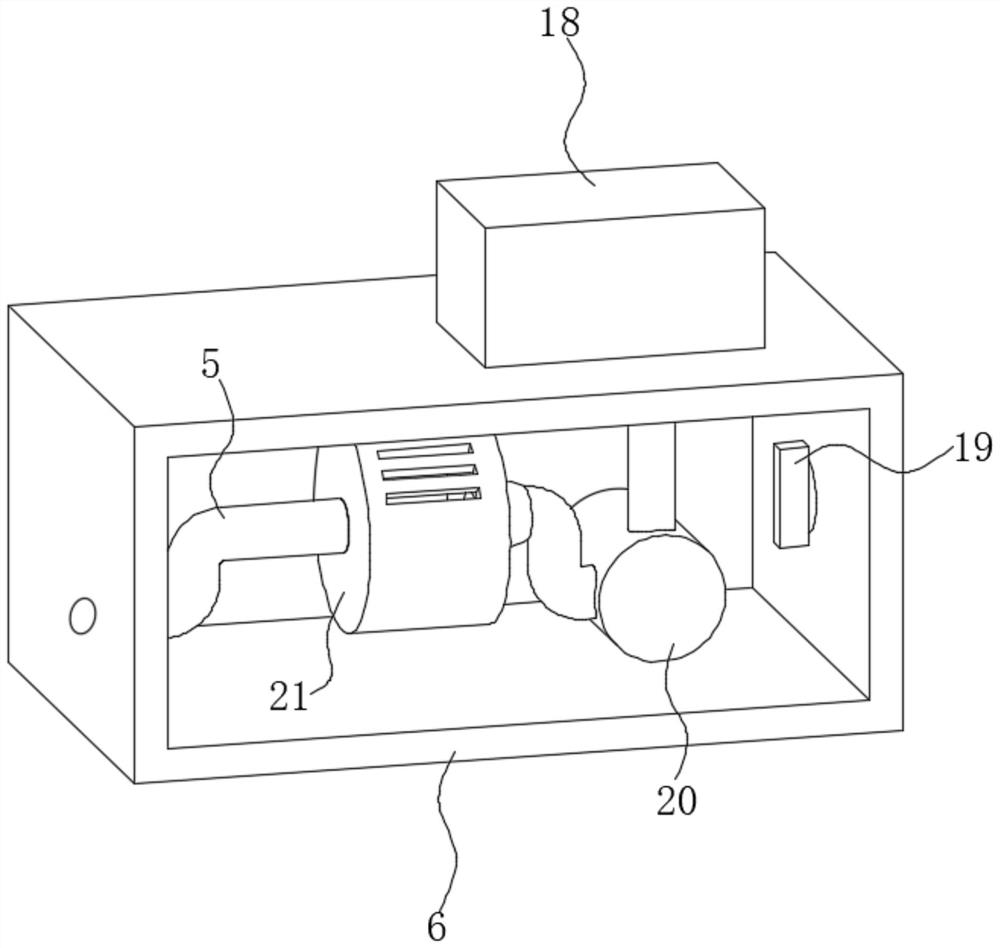

[0038] see Figure 1-6 , a multi-stage jet-type water-soluble exhaust gas recovery system and exhaust gas recovery process, including an injector 1, the right end of the injector 1 is fixedly connected with a flame arrester 2, and the left side of the injector 1 is fixedly connected with an intake pipe 3, and the flame arrester 2 The right end of the first three-terminal connecting pipe 5 is fixedly connected with the primary filter chamber 4 through the connecting pipe, and the outer wall of the primary filtering chamber 4 is fixedly connected with the first three-terminal connecting pipe 5 near the top. The front ends of the three branch pipes of the first three-terminal connecting pipe 5 are all The measuring chamber 6 is fixedly connected, and the front sides of the three measuring chambers 6 are fixedly connected with the second three-terminal connecting pipe 7, and the outer walls of the three branch pipes of the second three-terminal connecting pipe 7 are all fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com