Crushing instrument assembly and crushing instrument

A crushing instrument and component technology, applied in grain processing, etc., can solve the problems of poor precision and slow efficiency, and achieve the effect of high crushing efficiency and precise control of injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

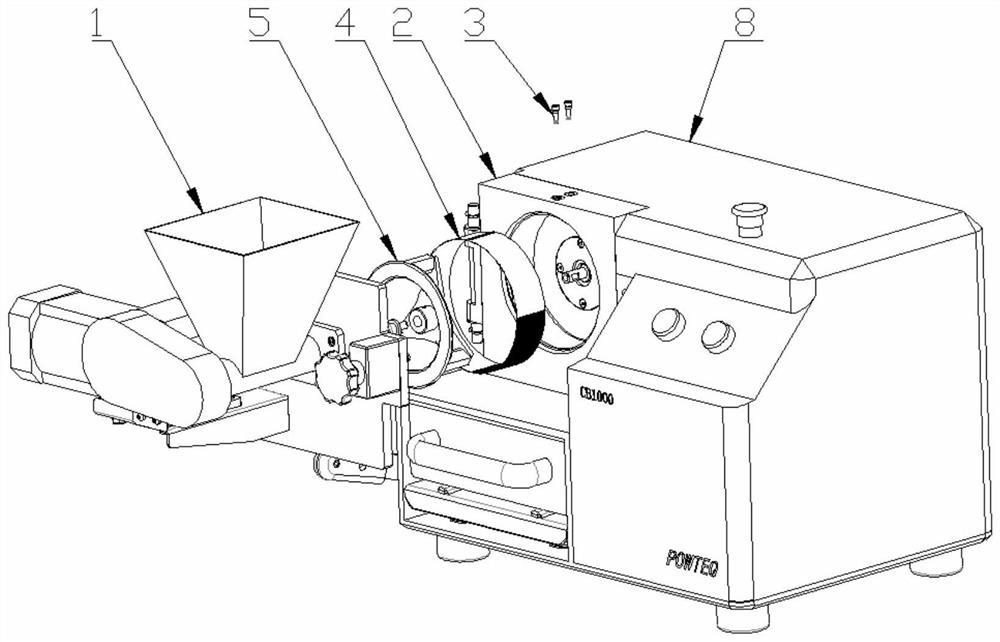

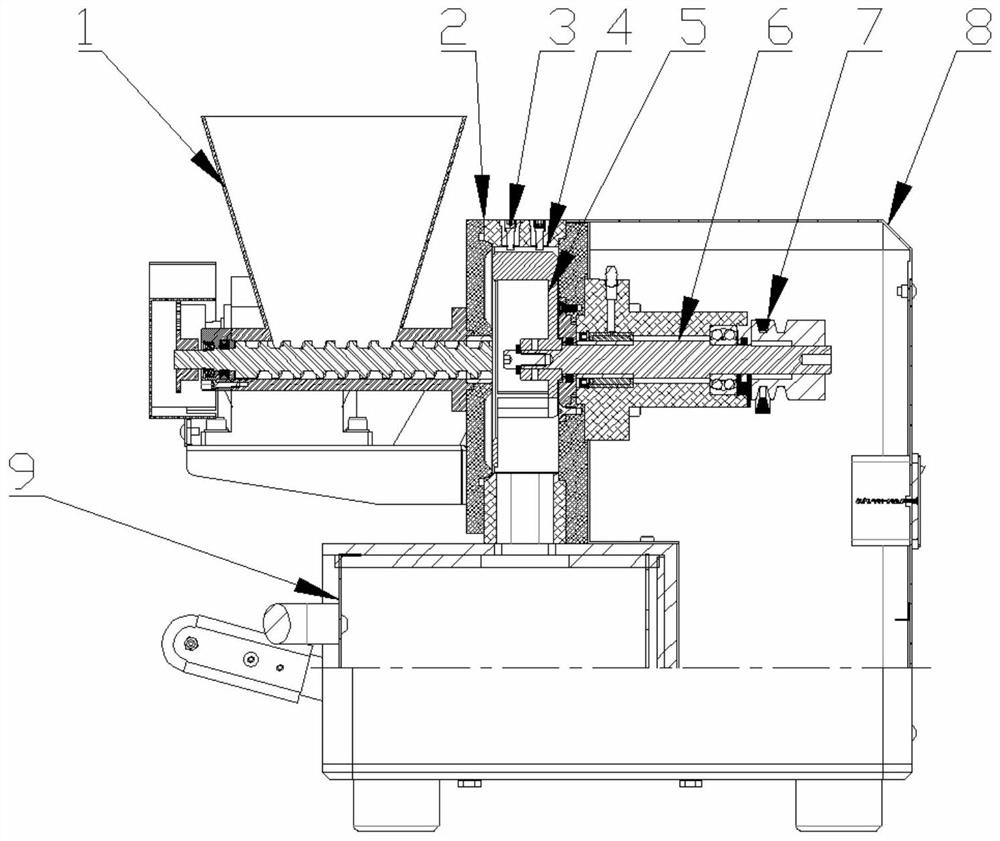

[0021] see in conjunction Figure 1 to Figure 3 As shown, according to an embodiment of the present application, a pulverizer assembly includes:

[0022] A sample feeding mechanism 1 and a crushing chamber 2, the outlet of the sample feeding mechanism 1 communicates with the crushing chamber 2;

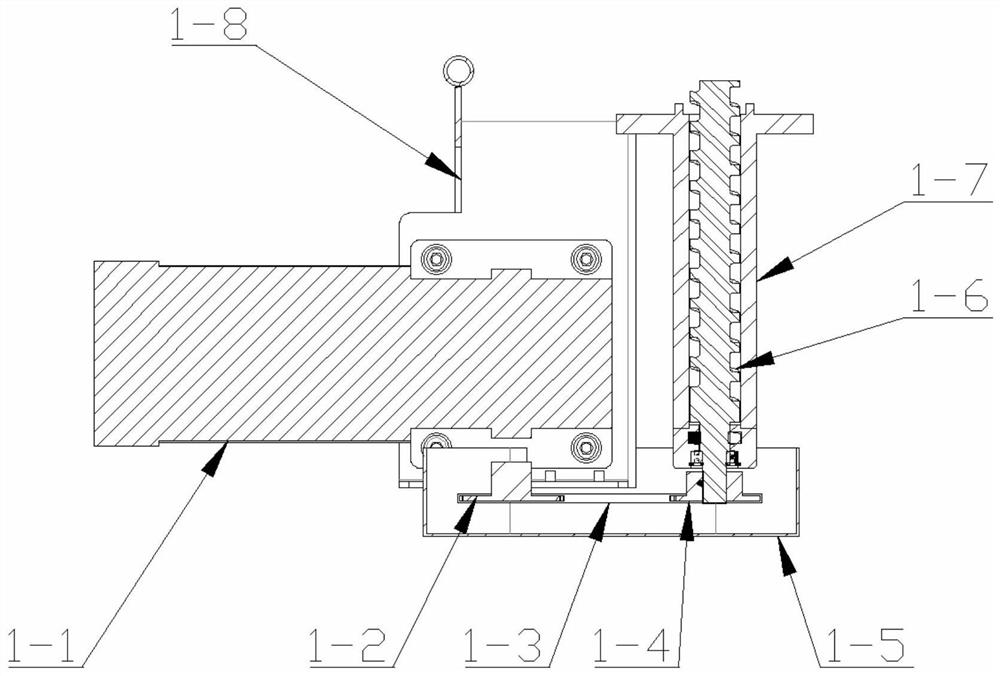

[0023] The sample feeding mechanism 1 includes a first drive assembly, a feed screw 1-6 and a feed bin, and the first drive assembly drives the feed screw 1-6 to rotate through a sprocket set; the feed screw 1-6 6 is located at the outlet of the silo, and the rotating feed screw 1-6 drives the material to move.

[0024] The outlet of the sample feeding mechanism 1 is connected to the crushing chamber 2, which is convenient for conveying materials into the crushing chamber 2; when the sample feeding mechanism 1 adopts a structure in which the driving assembly drives the feeding screw 1-6 through the sprocket, the driving assembly is easy to control, and the chain The wheel transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com