Pulse-jet dust removing device for bag-type dust collector

A technology of bag filter and pulse injection, which is applied to chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of high injection intensity, heavy maintenance workload, and high equipment cost, and achieve long-term filtration. Longer bag life, lower production cost, and adjustable blowing intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

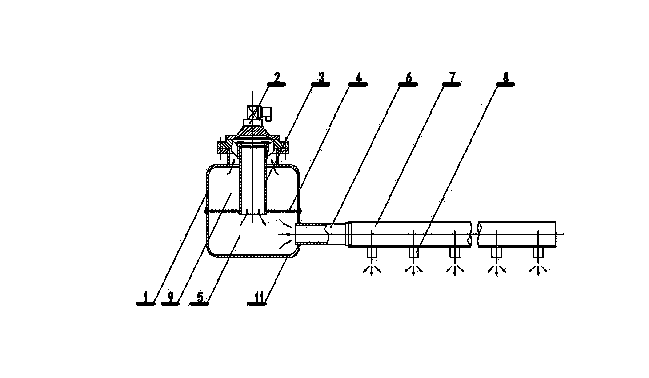

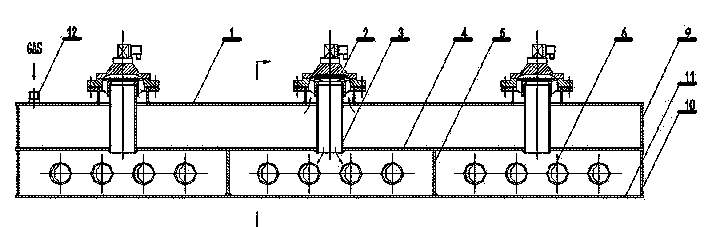

[0018] The bag type dust collector pulse jet dust cleaning device proposed by the present invention can be implemented in the following manner. Specific steps are as follows.

[0019] 1 Determine the volume of the air storage box (the cross-sectional size and length of the air storage box shell 1) according to the number of filter bags and the number of rows.

[0020] 2. The number of pulse valves 2 can be determined according to the nature of smoke and dust and the length of the gas tank shell 1.

[0021] 3. Drill a hole on the housing 1 of the air storage tank, and weld the base of the pulse valve 2 on it.

[0022] 4. Weld the gas storage tank shell 1 and the flat partition 4 to form the gas storage tank space.

[0023] 5. Weld the exhaust pipe 3 on the flat partition 4, and then install the pulse valve 2 on the base of the pulse valve 2.

[0024] 6. According to the number of filter bag rows, drill holes on the side of the gas distribution box shell 11, weld the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com