Device for full-automatically measuring kinematic viscosity and viscosity index of electrical equipment oil and measuring method

A technology of kinematic viscosity and viscosity index, applied in the direction of DC flow characteristic measurement, etc., to achieve the effect of ensuring accuracy, simple operation and reasonable sample injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0035] Example.

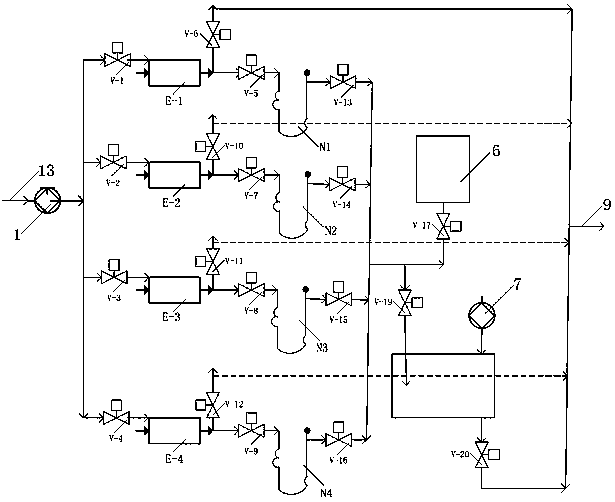

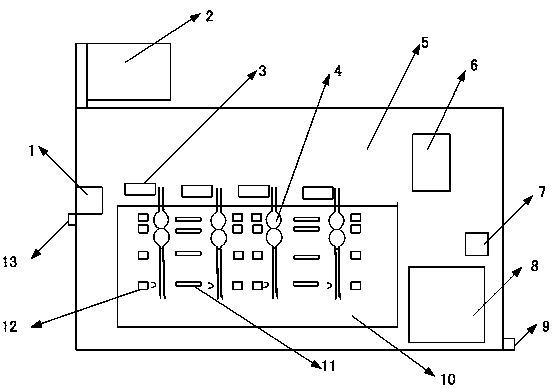

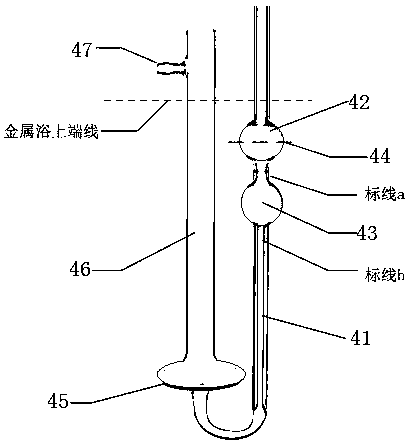

[0036] see Figure 1 to Figure 3 , a device for fully automatic determination of kinematic viscosity and viscosity index of oil used in electric equipment, including a device body, an electric pump pump unit 1, a microcomputer control panel 2, a quantitative tube and a propulsion device 3, a viscometer 4, insulating cotton and Relevant pipeline solenoid valve system 5, compression bottle and propulsion device 6, vacuum pump 7, vacuum bottle 88, oil discharge main outlet, metal constant temperature bath 10, monochromatic light emitting tube 11, photoelectric tube receiver and signal conversion system 12, sample injection Port 13; electric pump pumping unit 1, microcomputer control panel 2, vacuum p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com